Abstract: This research report focuses on the research status, preparation process, performance characteristics and application of coated diamond in many fields. It elaborates on the advantages of coated diamond compared to ordinary diamond, analyzes the impact of different coating processes on diamond performance, and looks into its future development trends, aiming to provide comprehensive information for the research, production and application of coated diamond. and in-depth reference basis.

1. Introduction

Diamond has excellent properties such as extremely high hardness, wear resistance, and thermal conductivity, and has broad application prospects in many fields such as mechanical processing, drilling, and electronics. However, the surface chemical activity of untreated diamond is low and the bonding force with the matrix material is weak, which limits the full use of its performance. Coated diamond technology effectively improves the interface bonding between diamond and matrix by depositing metal or other coatings on the diamond surface, significantly improving its overall performance and becoming one of the current research hotspots in the field of materials science.

2. Preparation process of coated diamond

(1) Electroplating method

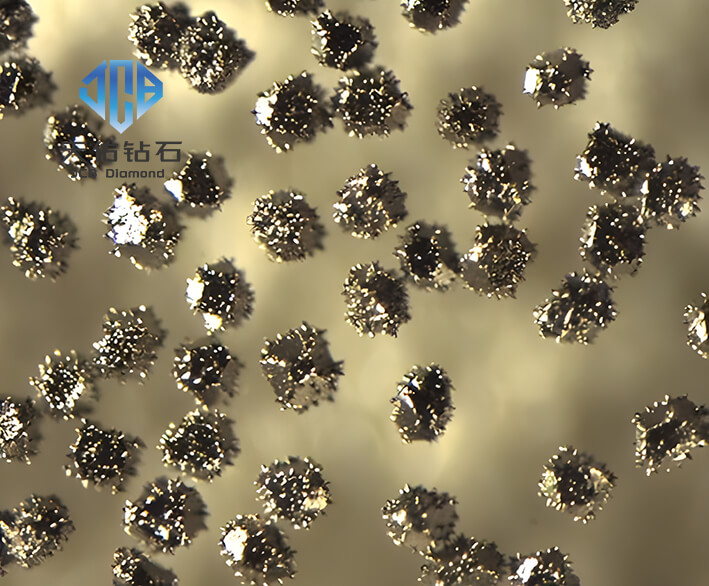

Electroplating is a commonly used preparation process for coated diamond. Its basic principle is to use electrolysis to reduce and deposit metal ions on the diamond surface to form a coating. During the electroplating process, diamond serves as the cathode, and the metal anode dissolves in the electrolyte to produce metal ions, which migrate to the diamond surface and deposit under the action of the electric field. For example, in the nickel plating process, nickel sulfate is commonly used as the nickel source, combined with boric acid and other buffers and additives, and the composition and process parameters of the electroplating solution (such as current density, temperature, pH value, etc.) are adjusted to obtain uniform and uniform nickel on the diamond surface. Dense nickel plating. The advantages of the electroplating method are mature technology, low cost, strong operability, and the ability to achieve large-scale production; the disadvantage is that the binding force between the coating and diamond is relatively limited, and the uniformity of the coating thickness is difficult to accurately control.

(2) Chemical plating method

Electroless plating is a method of depositing metal on the diamond surface based on chemical reactions and does not require an external electric field. Taking electroless nickel plating as an example, sodium hypophosphite is usually used as the reducing agent, and nickel is deposited on the diamond surface through an autocatalytic reaction in a solution containing nickel ions. The key to electroless plating lies in the formula design of the plating solution and the control of process conditions. Appropriate additives such as complexing agents, stabilizers, and accelerators are crucial to obtaining high-quality coatings. The electroless plating method can obtain a uniform coating on the surface of complex-shaped diamond, and the coating has good bonding force with diamond. However, the stability of the plating solution is poor, the cost is relatively high, and it is prone to environmental pollution problems.

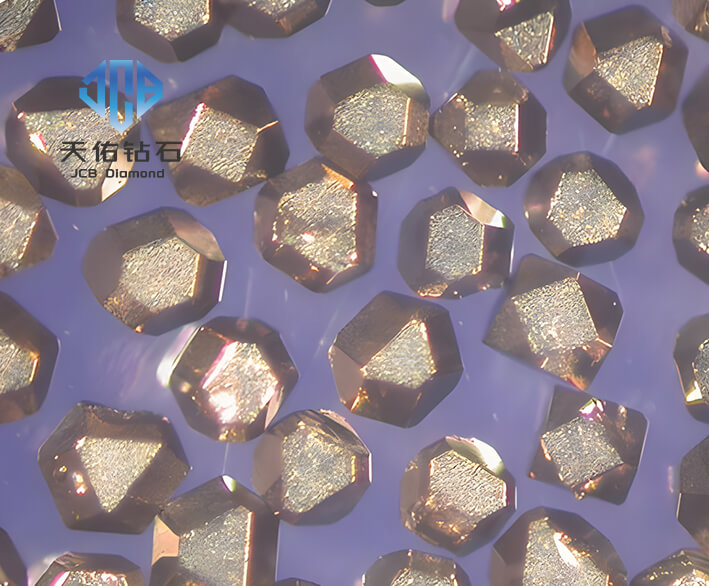

(3) Vacuum coating method

Vacuum coating technology includes methods such as physical vapor deposition (PVD) and chemical vapor deposition (CVD). PVD, such as magnetron sputtering coating, uses ions to bombard the target in a high vacuum environment, causing target atoms or molecules to be sputtered out and deposited on the diamond surface to form a coating. CVD generates coating materials in the gas phase through chemical reactions and deposits them on the diamond surface. For example, the hot wire CVD method is used to deposit a diamond film on the surface of diamond, which can further improve the hardness and wear resistance of diamond. The vacuum coating method can prepare a coating with high purity, good density, and strong bonding force, and can accurately control the thickness and composition of the coating. However, the equipment is expensive, the process is complex, and it requires high operating environment, so it is not suitable for large-scale industrial production.

3. Performance characteristics of coated diamond

(1) Improve the bonding force with the matrix

The existence of the plating layer increases the contact area and chemical bonding between the diamond and the substrate, effectively improving the interface bonding between the two. For example, in metal matrix composites, diamonds coated with metal layers can be better embedded in the matrix and are less likely to fall off when subjected to external forces, thereby improving the overall performance of the composite material. Experiments show that the bonding strength between nickel-plated diamond and copper matrix can be increased by more than 50% compared to unplated diamond.

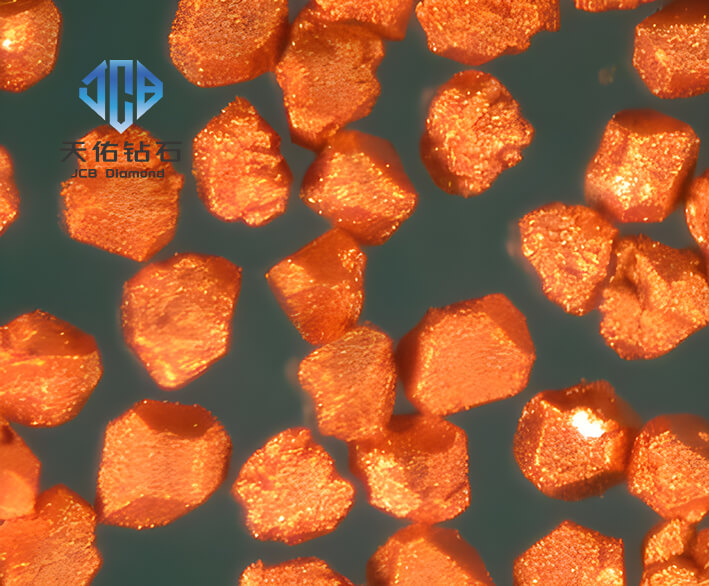

(2) Enhance wear resistance

The coating can form a protective film on the surface of the diamond to reduce the wear and tear of the diamond during use. At the same time, some coatings (such as cemented carbide coatings) themselves have high hardness and wear resistance, which further enhances the wear resistance of coated diamond. In the field of cutting processing, the service life of coated diamond tools can be significantly longer than that of ordinary diamond tools, effectively reducing processing costs.

(3) Improve thermal stability

For some application scenarios used in high-temperature environments, the coating layer can play a certain role in heat insulation and anti-oxidation, and improve the thermal stability of diamond. For example, when a diamond grinding wheel is used to grind high-temperature alloys, the coating can reduce thermal damage to the diamond at high temperatures and maintain the stability of its cutting performance.

(4) Change surface electrical properties

By plating different metals or conductive materials, the surface electrical properties of diamond can be changed so that it has certain conductivity or semiconductor properties. This provides the possibility for the application of diamond in the electronic field (such as diamond electrodes, electronic heat dissipation materials, etc.).

4. Application areas of coated diamond

(1) Superhard material tools

Coated diamond has been widely used in superhard material tools such as diamond tools, grinding wheels, and saw blades. In terms of cutting tools, coated diamond cutting tools can improve cutting efficiency and processing accuracy, and are suitable for processing high-hardness, difficult-to-cut materials, such as ceramics, cemented carbide, etc. In the field of grinding wheels and saw blades, coated diamond can enhance the wear resistance and service life of tools, improve the quality of processed surfaces, and is widely used in stone processing, metal cutting and other industries.

(2) Composite material reinforcement phase

As a reinforcing phase for composite materials such as metal matrix and ceramic matrix, diamond coating can significantly improve the mechanical properties of composite materials. For example, adding coated diamond particles to aluminum-based composites can increase the hardness of the composite by 30% - 50% and the strength by 20% - 30%, while maintaining good toughness. This kind of composite material has broad application prospects in aerospace, automobile manufacturing and other fields, and can be used to manufacture lightweight, high-performance parts.

(3) Electronic industry

In the electronics industry, coated diamond is used as heat dissipation material and electrode material due to its good thermal conductivity and electrical properties. For example, in high-power electronic devices, coated diamond heat sinks can effectively reduce chip temperature and improve the reliability and service life of the device. Diamond electrodes have the advantages of wide electrochemical window and low background current, and have potential application value in electrochemical analysis, electrochemical synthesis, etc.

(4) Drilling project

In petroleum and geological drilling projects, coated diamond drill bits can improve the wear resistance and cutting efficiency of the drill bit, reduce the wear and replacement frequency of the drill bit, and reduce drilling costs. Especially in drilling hard formations and complex formations, coated diamond drill bits have shown obvious advantages and can significantly increase drilling speed and depth.

5. Challenges and development trends in coated diamond research

(1) Challenges faced by research

The interface bonding mechanism between coating and diamond still needs to be further studied. Although the importance of chemical bonding and other effects in improving bonding strength has been recognized, there is still a lack of systematic and comprehensive understanding of the specific bonding mechanism under different coating materials and diamond surface states, which limits further optimization of coating performance.

The optimization and innovation of plating processes face many technical difficulties. For example, how to improve plating efficiency, reduce costs, and reduce environmental pollution while ensuring the quality of the plating is a key issue that needs to be solved in current electroplating and electroless plating processes. For the vacuum coating process, how to localize the equipment, reduce equipment costs, and improve the stability and repeatability of the process are also difficulties that need to be overcome.

There are few studies on the performance evolution of coated diamond under multi-field coupling conditions (such as high temperature, high pressure, high humidity and complex stress fields, etc.). With the continuous expansion of its application fields, performance reliability under extreme working conditions has become the focus of attention, but the current relevant experimental research and theoretical models are not perfect enough.

(2) Development trends

Develop new plating materials and composite coatings. In addition to traditional metal coatings (such as nickel, copper, cobalt, etc.), in the future it is expected to develop coatings with higher hardness, better wear resistance, stronger corrosion resistance and special functions (such as self-lubrication, biocompatibility, etc.) New coating materials. At the same time, the research and application of composite coatings (such as metal-ceramic composite coatings, multi-layer composite coatings, etc.) will also become a hot spot, and the comprehensive performance of coated diamond will be further improved through the synergy of different materials.

Multi-scale, multi-disciplinary interdisciplinary research. Combining microscopic characterization techniques (such as scanning electron microscopy, transmission electron microscopy, atomic force microscopy, etc.) and macroscopic performance testing, the structure-property relationship of coated diamond can be in-depth studied from the atomic and molecular scale to the macroscopic scale. At the same time, we integrate multidisciplinary knowledge such as materials science, physics, chemistry, and mechanics to establish a more complete theoretical model to provide scientific guidance for the design, preparation, and application of coated diamond.

Green and sustainable development. In the context of increasingly stringent environmental protection requirements, the coated diamond preparation process will develop in the direction of green, low pollution, and low energy consumption. For example, the development of cyanide-free electroplating processes, environmentally friendly chemical plating solutions, and high-efficiency and energy-saving vacuum coating technology can achieve the sustainable development of the coated diamond industry.

Expand emerging application areas. With the continuous advancement of science and technology, coated diamond is expected to be applied in emerging fields such as new energy, biomedicine, and quantum information. For example, in the field of new energy, it can be used to manufacture high-performance battery electrode materials; in the field of biomedicine, it can be used as a biosensor or hard tissue repair material; in the field of quantum information, its potential application value in quantum computing and quantum communications can be explored.

6. Conclusion

As a material with broad application prospects, the research and development of coated diamond has made significant progress in recent years. Coatings with different properties can be prepared on the diamond surface through a variety of plating processes, which effectively improves the bonding force between diamond and the matrix, wear resistance, thermal stability and electrical properties. It is widely used in superhard material tools, composite materials, electronics, etc. It plays an important role in many fields such as industry and drilling engineering. However, there are still challenges such as insufficient research on the interface bonding mechanism, difficulties in optimizing the plating process, and insufficient research on multi-field coupling performance. In the future, with the development of new coating materials, the in-depth multi-disciplinary research, the development of green preparation processes and the expansion of emerging application fields, coated diamond will show greater development potential in the field of materials science, and will promote related industries. Provide strong support for technological upgrading and innovative development.