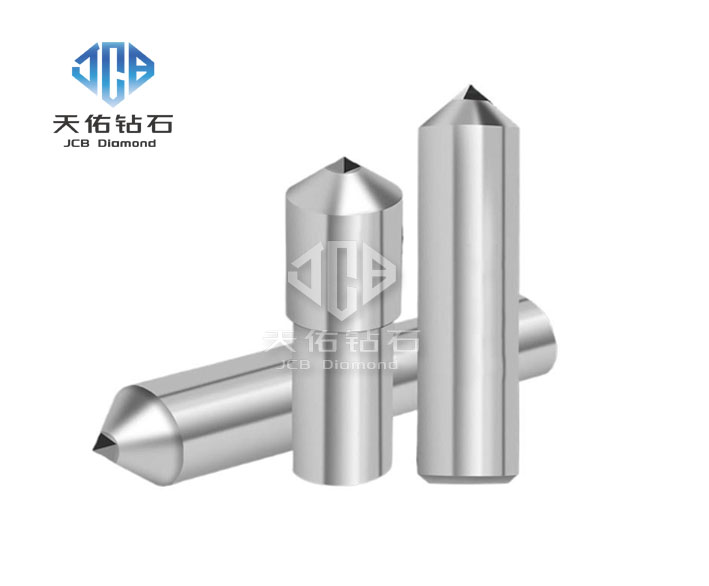

PCD tool

Industrial developed countries have carried out research on PCD tools earlier, and its application has been relatively mature. Since the first synthetic diamond was synthesized in Sweden in 1953, the research on the cutting performance of PCD tools has obtained a lot of results, and the application range and usage of PCD tools have expanded rapidly. At present, the world famous synthetic diamond composite sheet manufacturers are mainly DeBeers Company in the United Kingdom, GE Company in the United States, Sumitomo Electric Co., LTD. It is reported that in the first quarter of 1995, the production of PCD tools in Japan alone reached 107,000. The application range of PCD tool has been extended from the initial turning processing to drilling and milling processing. A survey conducted by a Japanese organization on superhard tools shows that the main consideration for people to choose PCD tools is based on the advantages of surface accuracy, dimensional accuracy and tool life after PCD tool processing. Diamond composite sheet synthesis technology has also been greatly developed, DeBeers Company has launched 74mm diameter, layer thickness of 0.3mm polycrystalline diamond composite sheet.

The domestic PCD tool market is also expanding with the development of tool technology level. At present, China First Automobile Group has more than 100 PCD turning tool use points, many wood-based panel enterprises also use PCD tools for wood product processing. The application of PCD tool has further promoted the research of its design and manufacturing technology. In China, Tsinghua University, Dalian University of Technology, Huazhong University of Science and Technology, Jilin University of Technology, Harbin Institute of Technology and so on are actively carrying out research in this area. At present, the processing range of PCD tools has been extended from traditional metal cutting to stone processing, wood processing, metal matrix composite materials, glass, engineering ceramics and other materials processing. Through the analysis of the application of PCD tools in recent years, it can be seen that PCD tools are mainly used in the following two aspects: ① Processing non-ferrous metal materials that are difficult to process: When processing non-ferrous metal materials that are difficult to process with ordinary tools, they often produce defects of easy tool wear and low processing efficiency, while PCD tools can show good processing performance. For example, the PCD tool can effectively process a new type of engine piston material - silicon aluminum alloy (the research on the processing mechanism of the material has made a breakthrough). ② Processing difficult to process non-metallic materials: PCD tool is very suitable for stone, hard carbon, carbon fiber reinforced plastic (CFRP), artificial plate and other difficult to process non-metallic materials processing. For example, Huazhong University of Science and Technology realized the PCD tool processing glass in 1990; At present, the application of reinforced composite flooring and other wood-based panels (such as MDF) is becoming more and more widespread, and the processing of these materials with PCD tools can effectively avoid the defects such as easy tool wear.

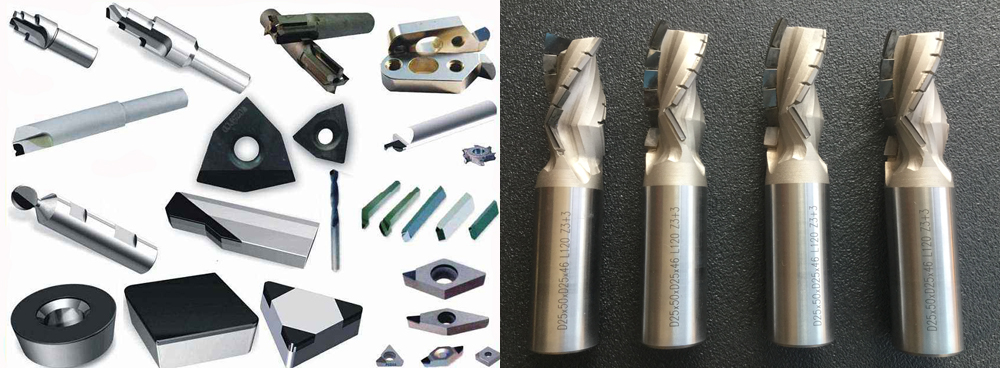

PCBN tool

PCBN tool is an artificial cubic boron nitride tool, which can maintain high hardness characteristics at high temperatures, mainly for processing black metal. Cubic Boron Nitride (Cubic Boron Nitride) was first synthesized by the United States General Electric (GE) company in the 1950s using artificial methods under high temperature and high pressure conditions, and its hardness is second only to diamond and far higher than other materials, so it is collectively known as superhard materials with diamond.

Application field

Suitable for high-speed and ultra-high-speed cutting technology:

PCBN tool is suitable for high-speed cutting of cast iron, hardened steel and other materials. From the PCBN tool cutting cast iron and hardened steel tool back tool wear and cutting distance relationship can be seen: when the cutting speed exceeds a certain limit, the higher the cutting speed, PCBN tool back tool wear speed is smaller, that is, high-speed cutting tool life is higher, this feature is especially suitable for modern high-speed cutting processing.

Suitable tool materials for hard cutting technology

The finishing of hardened hardware (hardness HRC55 or more) is usually completed by grinding processing, but with the development of tool materials and the improvement of machining accuracy of lathes (especially CNC lathes), hard cutting is used instead. Grinding to complete the final processing of parts has become a new way of finishing, this process method of turning instead of grinding has the following advantages:

(1) can improve the processing flexibility, break through the restrictions of grinding wheel grinding, by changing the cutting edge and the way of moving the tool can process different geometric shapes of the workpiece;

(2) The environmental problems in cutting processing are becoming more and more serious, the waste liquid and waste generated by grinding processing are more and more difficult to deal with and remove, and harmful to the human body, and the hard cutting does not need to add coolant, which is of great significance;

(3) High cutting efficiency, short processing time, small equipment investment costs, can reduce processing costs;

(4) The energy consumed by cutting the same volume is only 20% of the grinding, so the cutting heat generated is less, the machining surface is not easy to cause burns and tiny cracks, and it is easy to maintain the integrity of the workpiece surface performance;

(5) Under the same metal removal rate, hard cutting saves energy than grinding.

The tool materials usually used for hard cutting are ceramic, TiC coated blades and PCBN tool materials, but to perform hard turning at higher speeds (1000m/min or more), PCBN is a suitable tool material variety. Such as in the automotive gearbox synchronizer sleeve fork (material is 20CrMnTi, hardness is HRC58 ~ 62) processing with car grinding, the efficiency is increased by more than 4 times, and the processing cost is reduced to 1/3 ~ 1/2 of the original grinding process.

Ideal tool material for dry cutting processes

Due to the reasons of economy and environmental protection, dry cutting machining method has become a key research topic in the field of machinery manufacturing in recent years. Let's first look at the problems caused by the use of cutting fluid in the wet cutting process:

(1) Long-term exposure to the air or the cutting heat caused by the cutting fluid mist volatilization, easy to pollute the environment, harm the health of the operator, the cutting fluid in the sulfur, chlorine and other additives more harmful, affecting the quality of the processing surface;

(2) The use of cutting fluid affects the processing cost, according to statistics, cutting fluid accounts for 15% of the production cost, while the tool cost accounts for only 3% to 4%;

(3) Leakage and overflow of cutting fluid will pollute the environment and prone to safety and quality accidents;

(4) The transmission, recovery, filtration and other devices of cutting fluid and their maintenance costs are higher, which increases the production cost.

Due to the above reasons, dry cutting processing technology has been applied in the Western industrial developed countries. The "Red Crescent" dry cutting process recommended by Makino Company in the United States can give full play to the cutting performance of the tool and greatly improve productivity compared with wet cutting. The mechanism is that due to the high cutting speed, the heat generated is concentrated in the front of the tool, so that the material near the cutting zone reaches a red hot state, the yield strength decreases, and the effect of improving the cutting efficiency is achieved. The premise of the red crescent dry cutting process is that at a higher cutting temperature, the strength of the cut material has been significantly reduced, becoming easy to cut, and the strength of the tool material in the same state to have better red hardness and thermal stability, but also have better wear resistance and resistance to bonding.

Suitable for dry cutting process tool materials are ceramic, cermet, coated carbide and PCBN tool materials, etc., but in terms of red hardness and thermal stability, PCBN material is suitable for dry cutting process tool materials, and because PCBN tool materials have the above advantages, more suitable for high-speed dry cutting processing. The comparison between dry cutting and wet cutting of grey cast iron with PCBN tool can be seen that PCBN has a higher tool life than wet cutting in the case of high-speed dry cutting.

Suitable for automatic processing and difficult material processing

PCBN cutter has high hardness and wear resistance, and can process high-precision parts (small size dispersion) for a long time at a high cutting speed, greatly reducing the number of tool changes and the time spent on tool wear compensation downtime. Therefore, it is very suitable for CNC machine tools and processing equipment with a high degree of automation, and can make the high efficiency of the equipment fully play.

In the application of difficult materials, PCBN tool also shows its excellent performance, such as surface spray welding (coating) material processing, machining with other materials, tool life is very low, can not be processed by grinding method, and PCBN is the only suitable tool material; For example, the high alloy wear-resistant cast iron used in petroleum power plant equipment, the use of PCBN tools than carbide tools to improve the cutting efficiency of more than 4 times, the cost of a single tool reduced to 1/5 of the original. In addition, in the cutting of sintered materials such as cemented carbide, PCBN tools also show good cutting performance.

PCBN tool application case

Because PCBN has high hardness and wear resistance, and does not react with iron group metals at high temperatures, it is mainly used for the cutting of high hardness materials and difficult materials, such as hardened steel, high alloy wear-resistant cast iron, high temperature alloy, high-speed steel, surface spray welding materials, sintered metal materials and other difficult materials.

(1) Processing hardened steel, can play the effect of turning instead of grinding, because the cutting depth is more than ten times larger than the grinding depth, so the processing efficiency is high, the surface does not produce burns. For example, when the variable speed sliding gear (20CrMnTi, hardness HRC58 ~ 62) is processed by the lathe, the cutting efficiency is more than 4 times higher than that of the original grinding.

(2) Processing high alloy (including tungsten or chromium 18%) wear-resistant cast iron, cutting speed is more than 10 times higher than carbide cutting tools, cutting efficiency is more than 4 times higher.

(3) Processing of high cobalt chromium molybdenum corrosion and heat resistant alloy, PCBN tool cutting speed of 160m/min, is 8 times the carbide tool.

(4) Processing thermal spraying (spray welding) materials, the surface spray welding parts can not be processed by grinding, and the cutting efficiency of cemented carbide tools is very low, and the processing efficiency can be improved after using PCBN tools, saving more than 50% of processing costs. PCBN tool can also be used for non-ferrous metal precision cutting and sintered metal cutting processing and so on.