Wire-drawing die

Wire drawing die usually refers to a variety of drawing dies for metal wire, as well as drawing dies for fiber optics. All drawing dies have a hole in the center of a certain shape, round, square, octagonal or other special shape. As the metal is pulled through the die, its size decreases and even its shape changes. A steel die is sufficient for pulling soft metals (such as gold and silver), and there can be multiple holes of different apertures in the die.

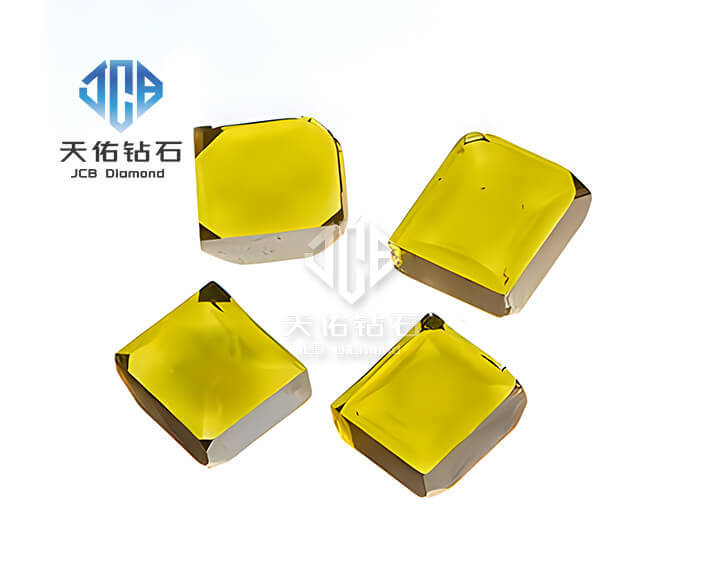

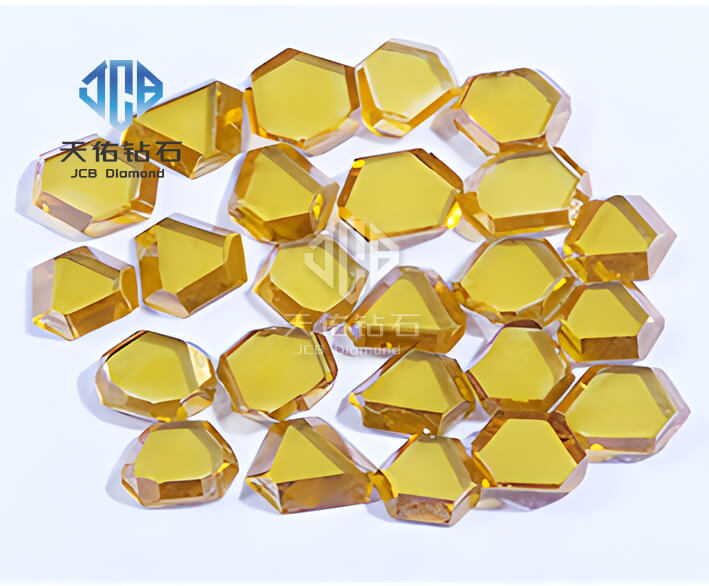

Wire drawing die is widely used, such as electronic devices, radar, television, instruments and aerospace used in high-precision wire and commonly used tungsten wire, molybdenum wire, stainless steel wire, wire and cable wire and various alloy wires are drawn with diamond wire drawing die, diamond drawing die due to the use of natural diamond, artificial diamond, polycrystalline diamond and CVD diamond as raw materials, Therefore, it has strong wear resistance and extremely high service life.

After decades of development, there have been many new wire drawing die materials. According to the type of material, wire drawing die can be divided into alloy steel die, carbide die, natural diamond die, diamond die, polycrystalline diamond die, CVD diamond die and ceramic die. The development of new materials has greatly enriched the application range of wire drawing die and increased the service life of wire drawing die.

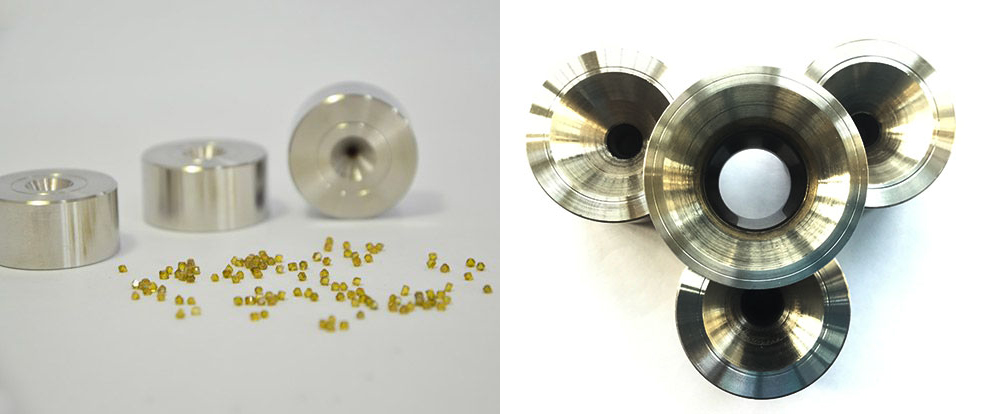

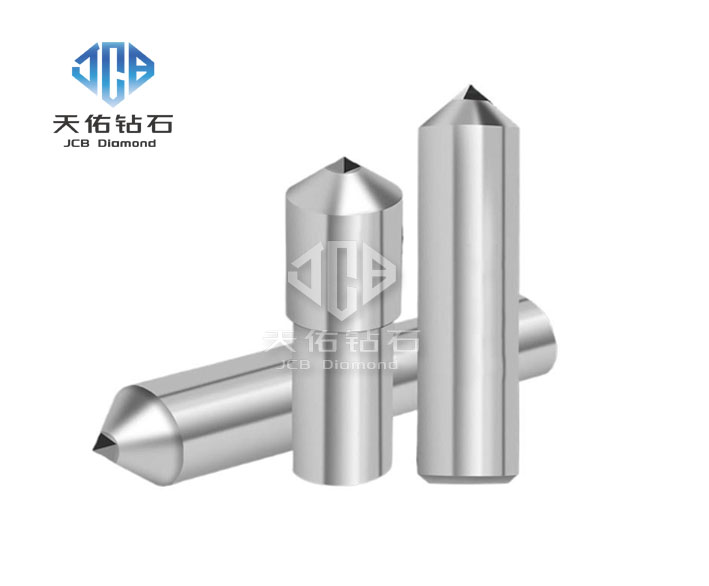

The structure of the wire drawing die core can be divided into five sections according to the nature of work: "entrance area, lubrication area, work area, sizing area and exit area". The inner diameter profile of the wire drawing die is very important, it determines the tension required to compress the wire and affects the residual stress in the wire after drawing. The function of each area of the mold core is: the entrance area, which facilitates threading and prevents the steel wire from chafing the wire drawing die from the entrance direction; Lubrication area, through which the steel wire is easy to bring lubricant; The working area is the main part of the die hole, where the deformation process of the steel wire is carried out, that is, the original section is reduced to the required section size. When drawing conical surface metal, the space occupied by the volume of the metal in the working area is a round table, which is called the deformation zone. The cone half Angle α (also known as the die half Angle) in the working area is mainly used to determine the size of the drawing force; The function of the sizing zone is to obtain the exact size of the drawn wire. The outlet area is used to prevent the wire outlet from being unstable and scratching the wire surface.

With the increase of wire drawing speed, the service life of wire drawing die has become a prominent problem. Americans T Maxwall and E G Kennth proposed a new drawing die pass theory for high-speed drawing, that is, the "straight line" theory. The drawing die made according to the theory has the following characteristics:

① The inlet area and the lubrication area are combined into one, which has the tendency to reduce the lubrication Angle, so that the lubricant is subjected to a certain pressure before entering the work area, so as to achieve better lubrication effect.

② The inlet area and working area are lengthened to establish a better lubrication pressure, and the Angle is optimized according to the drawing material and the compression rate per pass.

The sizing zone must be straight and reasonable in length.

④ The vertical lines of each part must be flat and straight.