Diamond & CBN grinding wheel

Using diamond and CBN (cubic boron nitride) abrasive as raw materials, using metal binder, resin binder, ceramic binder and electroplating binder to make a variety of shapes of grinding wheels for grinding, grinding, polishing, CBN compared to diamond grinding wheel in the processing of black metal has more advantages.

The grinding wheel made of diamond and CBN abrasive can be divided into the following four kinds according to different processing processes and different components of the binder used, and their properties and uses (referring to mechanical processing uses) are also different.

Electroplated diamond & CBN grinding wheel

The forming process of grinding wheel is simple and the production cost is low. The molding is simple but there is only one layer of coating, which cannot be corrected, and it is difficult to know when the grinding layer is damaged during the processing. It is suitable for small batch machining and geometric complex forming mill processing and as a dressing roller.

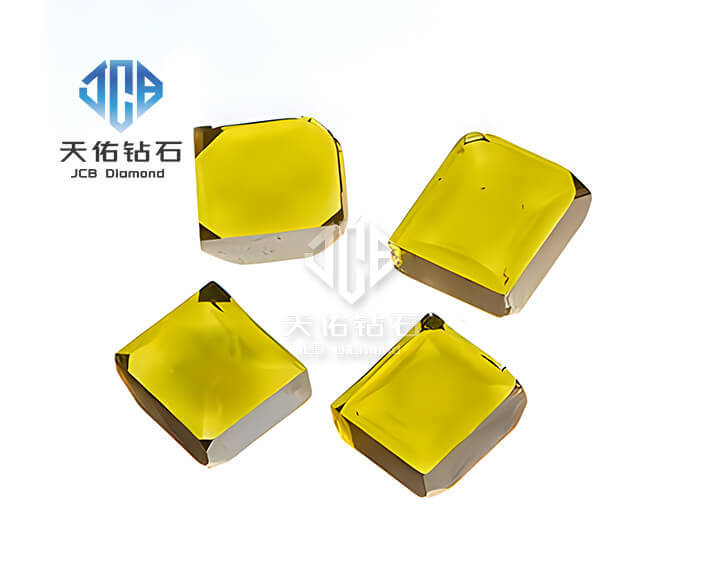

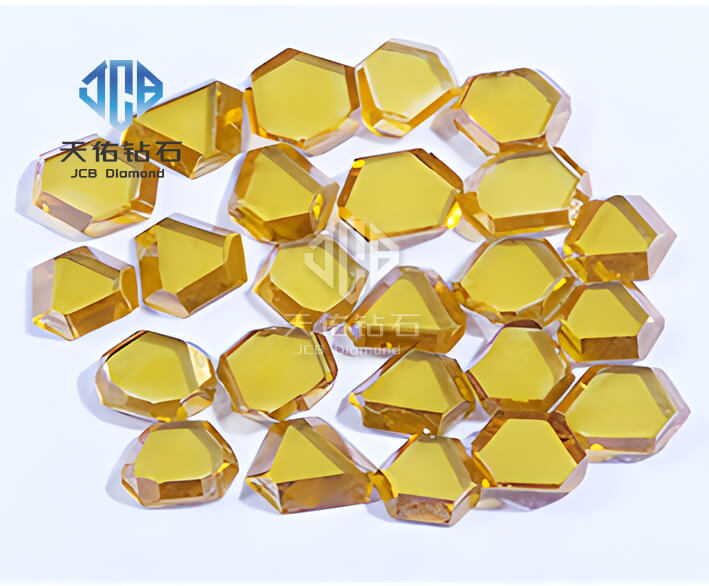

Sintered diamond; CBN grinding wheel

High hardness and high density, processing into high-precision dressing roller, high cost. It is mainly used for dressing roller of grinding wheel and processing of large quantities of superhard materials.

Resin diamond & CBN grinding wheel

The production process of grinding wheel is simple and the production cost is low. The molding is simple but not easy to correct. For multi-shape and small batch processing. Such as tool grinding and tool processing, and glass processing.

Ceramic bond diamond & CBN grinding wheel

Ceramic bond for diamond & CBN grinding wheel has the advantages of strong grinding force, high-speed processing does not burn the workpiece, can be corrected and durable, is currently the ideal high-speed, efficient and high-precision grinding tool.

Diamond grinding wheel is the ideal choice for optical materials, glass, ceramics, gems, stone and other hard and brittle materials and cemented carbide grinding. With the progress of The Times, the development of science, the needs of society, the development of new materials, grinding processing to the direction of high quality, high precision, high efficiency, automation continues to develop, the role of diamond grinding wheel is becoming more and more obvious, metal bond diamond grinding wheel on the grinding particle control strength is high, long life, less wear. The diamond grinding wheel gives full play to its characteristics of strong abrasion resistance and cutting ability in high-speed and ultra-high-speed high-precision grinding, especially in hard and brittle materials, and is widely used. Diamond grinding wheels have almost all applications in various sectors and fields of industry, aerospace, mold manufacturing, semiconductor manufacturing, optical processing manufacturing and so on. At present, ceramic materials, optical materials, aircraft engine turbine blades, silicon products, etc., are multi-purpose diamond grinding wheel.

Cubic boron nitride (CBN) grinding wheel is suitable for processing the following materials: ① high manganese steel; ② High chromium, nickel, molybdenum alloy steel; ③ Chilled cast iron (HS80 ~ 90); ④ All kinds of hardened steel (HRC55 ~ 65); ⑤ All kinds of cast iron (HB200 ~ 400), etc., and has been in the domestic automobile (gear, flywheel, shaft, bearing, etc. Processing), roll, slurry pump (impeller, vortex shell, guard plate, jacket, etc. Processing), mold, cylinder liner; It solves the cutting and processing of high-hardness difficult materials in all walks of life, and can improve work efficiency, greatly save processing hours and electricity, and obtain huge economic benefits.