Monocrystalline Wafer Technology Fuels Rapid Growth of Diamond Monocrystalline Wafer Market

Recently, driven by explosive demand in 5G communications, artificial intelligence, and high-end electronics, diamond monocrystalline wafers, as a core component of next-generation semiconductor materials, have become a focal point in global technology. With ultra-high thermal conductivity, excellent electrical insulation, and exceptional physical stability, diamond monocrystalline wafers are gaining significant attention for applications in power devices, lasers, quantum computing, and beyond.

Compared to traditional silicon-based materials, diamond monocrystalline wafers exhibit thermal conductivity over 5 times higher and can withstand higher voltages and extreme temperatures. This makes them ideal for high-frequency, high-power electronic devices. Industry analysts predict the global diamond monocrystalline wafer market will exceed $5 billion by 2030, with a compound annual growth rate (CAGR) of over 25%.

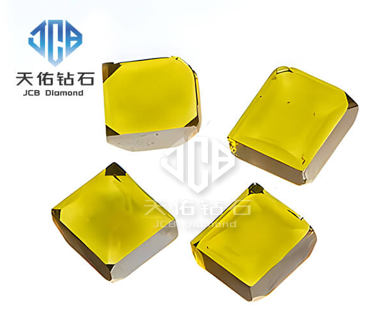

In this competitive landscape, top-tier diamond monocrystalline wafer manufacturers are enhancing their advantages through innovation. For instance, a leading international manufacturer recently announced the mass production of diamond monocrystalline wafers with diameters exceeding 100mm, significantly reducing production costs. Meanwhile, diamond monocrystalline wafer manufacturers in China, the U.S., and Japan are increasing R&D investments to advance chemical vapor deposition (CVD) and high-temperature high-pressure (HTHP) technologies.

Currently, diamond monocrystalline wafers are widely used in:

· Semiconductors: Enabling high-power-density chips with improved thermal management;

· Optical Devices: Serving as premium substrates for infrared windows and laser lenses;

· Quantum Technologies: Providing stable signal transmission carriers for quantum computers.

Multiple downstream companies have formed strategic partnerships with diamond monocrystalline wafer manufacturers to accelerate industrial adoption.

As global carbon neutrality goals advance, diamond monocrystalline wafer manufacturers are pioneering low-carbon production methods. Some companies now synthesize diamonds using recycled industrial carbon emissions, reducing energy consumption and environmental impact. This innovative approach may set new sustainability benchmarks for the industry.