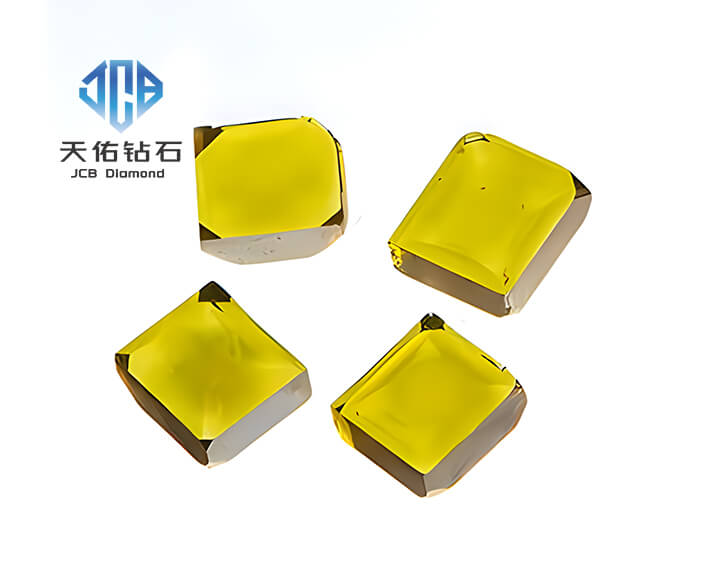

Features:

Extremely high hardness: Diamond is the hardest substance in nature, which makes diamond single crystal have excellent wear resistance and scratch resistance, and can maintain good shape and dimensional stability during processing and use.

High thermal conductivity: Diamond has very high thermal conductivity, for example, its thermal conductivity is about 5 times that of copper and silver, which makes diamond single crystal have excellent performance in the field of heat dissipation. It can be used as a heat dissipation material for high-power electronic devices,

which can effectively conduct the heat generated by electronic devices, reduce the operating temperature of the device, and improve the reliability and service life of the device.

Good insulation performance: Diamond is a good insulator, which makes it can be used as an insulating material in the field of electronics, especially in special environments such as high frequency and high voltage, which can ensure the normal operation of electronic devices.

Excellent optical performance: Diamond has good light transmittance and refractive index in the optical field, and can be used to manufacture optical components such as optical windows and lenses.

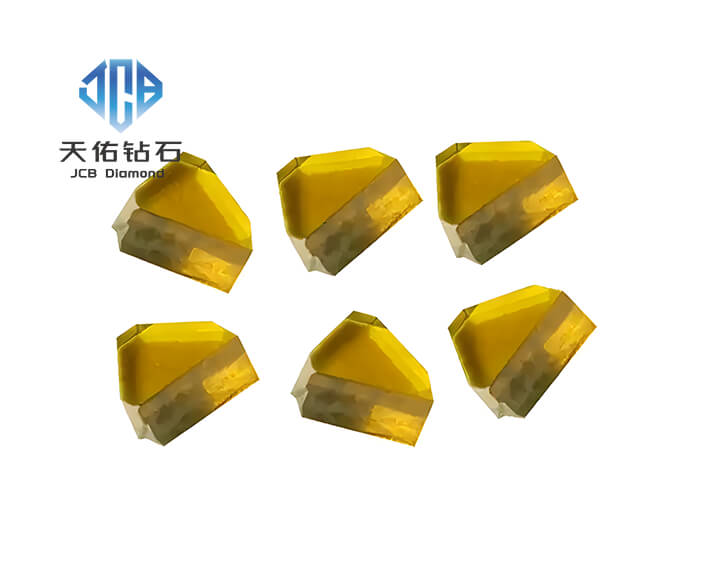

Preparation method:

Static pressure catalyst method: Under the condition of thermodynamic stability of diamond, diamond is synthesized by using ultra-high pressure and high temperature equipment and adding catalysts to participate in the reaction. This method can control the growth process of diamond and produce high-quality diamond single crystals,

but the equipment cost is high and the process is complicated.

Dynamic pressure method (explosion method): Synthesize diamonds using the high temperature and high pressure conditions generated by the explosion of explosives. The pressure and temperature conditions of this method are similar to those of the static pressure method without catalyst,

but the way of generating high temperature and high pressure is different. The advantages of the explosion method are fast reaction speed and relatively low cost, but the quality and dimensional stability of the synthesized diamond single crystal are relatively poor.

Metastable growth method: Growth is carried out under the pressure and temperature conditions of the metastable state of diamond. High-pressure equipment is not required and it is often carried out under normal pressure or negative pressure (vacuum). The advantages of this method are simple equipment and easy operation,

but the quality and performance of the synthesized diamond single crystal may not be as good as the products synthesized by the static pressure catalyst method.

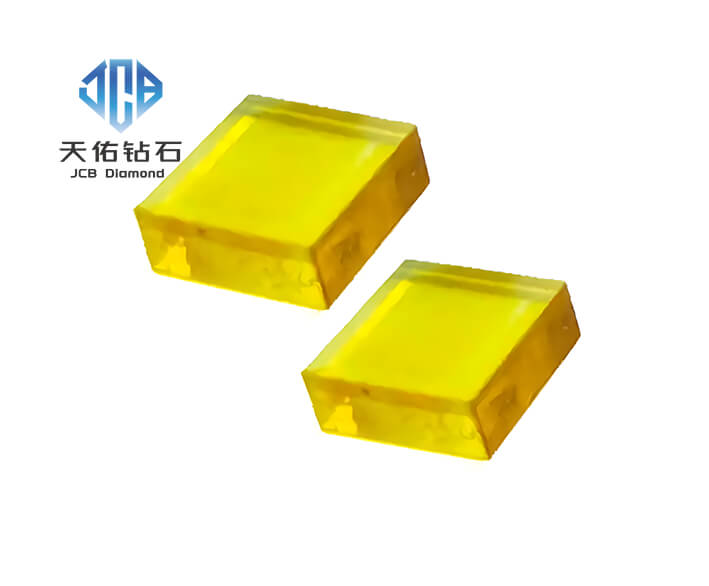

Application areas:

Electronic and electrical industry: It can be used to manufacture semiconductor devices. For example, diamond can be used as a semiconductor material to manufacture high-power, high-frequency electronic devices, such as radio frequency switches, amplifiers and transmitters; in the processing of semiconductor devices,

diamond grinding paste can be used to polish semiconductor materials to improve surface quality.

Optical glass and gem processing industry: Silicon carbide was used to process optical glass in the past, which was inefficient and had poor working conditions. Now diamond grinding tools are widely used, including cutting, nesting, cutting, edge grinding, and fine grinding of convex and concave surfaces.

Drilling and mining industry: It is widely used in drilling and mining such as petroleum, coal, metallurgy, and geological exploration. For example, the production of diamond drill bits can improve drilling efficiency and the service life of drill bits.

Construction and building materials industry: Diamond tools are widely used in the cutting and grinding of marble, granite, artificial cast stone, and concrete building materials.

Heat dissipation field: With its high thermal conductivity, it has become the preferred material for high-power heat dissipation and can be used for heat dissipation of high-power IGBT modules, semiconductor lasers, etc.