I. Characteristics of Synthetic Diamond Rough Materials

High Hardness

Synthetic diamond rough materials possess extremely high hardness, with a Mohs hardness of up to 10, being one of the hardest substances known so far. This enables them to effectively cut, grind and polish various hard materials in industrial processing.

For example, in the stone processing industry, synthetic diamond rough materials can be used to manufacture saw blades and grinding tools, which can quickly and efficiently cut hard stones such as marble and granite, improving processing efficiency and quality.

High Strength

Synthetic diamond rough materials have high strength and can withstand relatively large pressure and impact forces. This has led to their wide application in fields such as drilling and mining.

For example, in oil drilling, synthetic diamond rough materials can be used to make drill bits, which can drill into hard rock formations, increasing drilling speed and depth.

Good Thermal Stability

Synthetic diamond rough materials can still maintain relatively high hardness and strength at high temperatures, having good thermal stability. This enables them to exhibit stable performance in high-temperature processing environments.

For example, in the glass processing industry, synthetic diamond rough materials can be used to make glass-cutting tools, which can quickly and accurately cut glass at high temperatures, improving processing efficiency and quality.

Chemical Stability

Synthetic diamond rough materials have good chemical stability and are not easily corroded by chemical substances such as acids and alkalis. This has resulted in their wide application in the chemical industry.

For example, in the manufacturing of chemical equipment, synthetic diamond rough materials can be used to make seals and valve components, which can maintain good performance in corrosive media, prolonging the service life of the equipment.

II. Production Methods of Synthetic Diamond Rough Materials

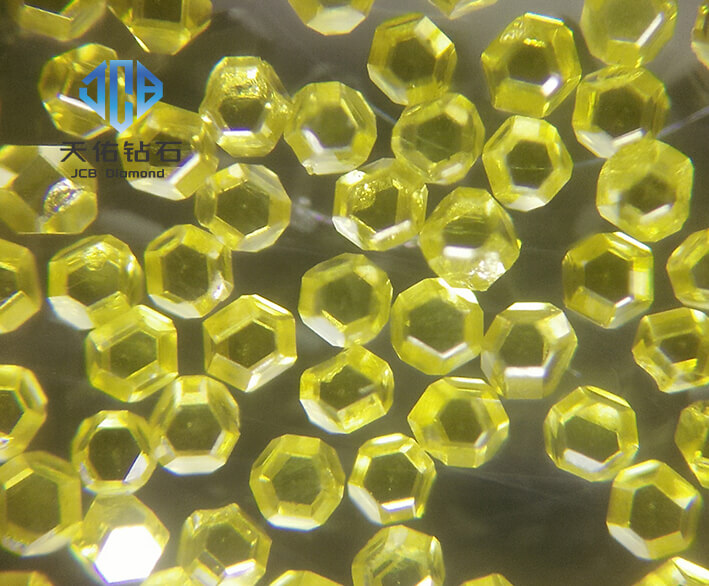

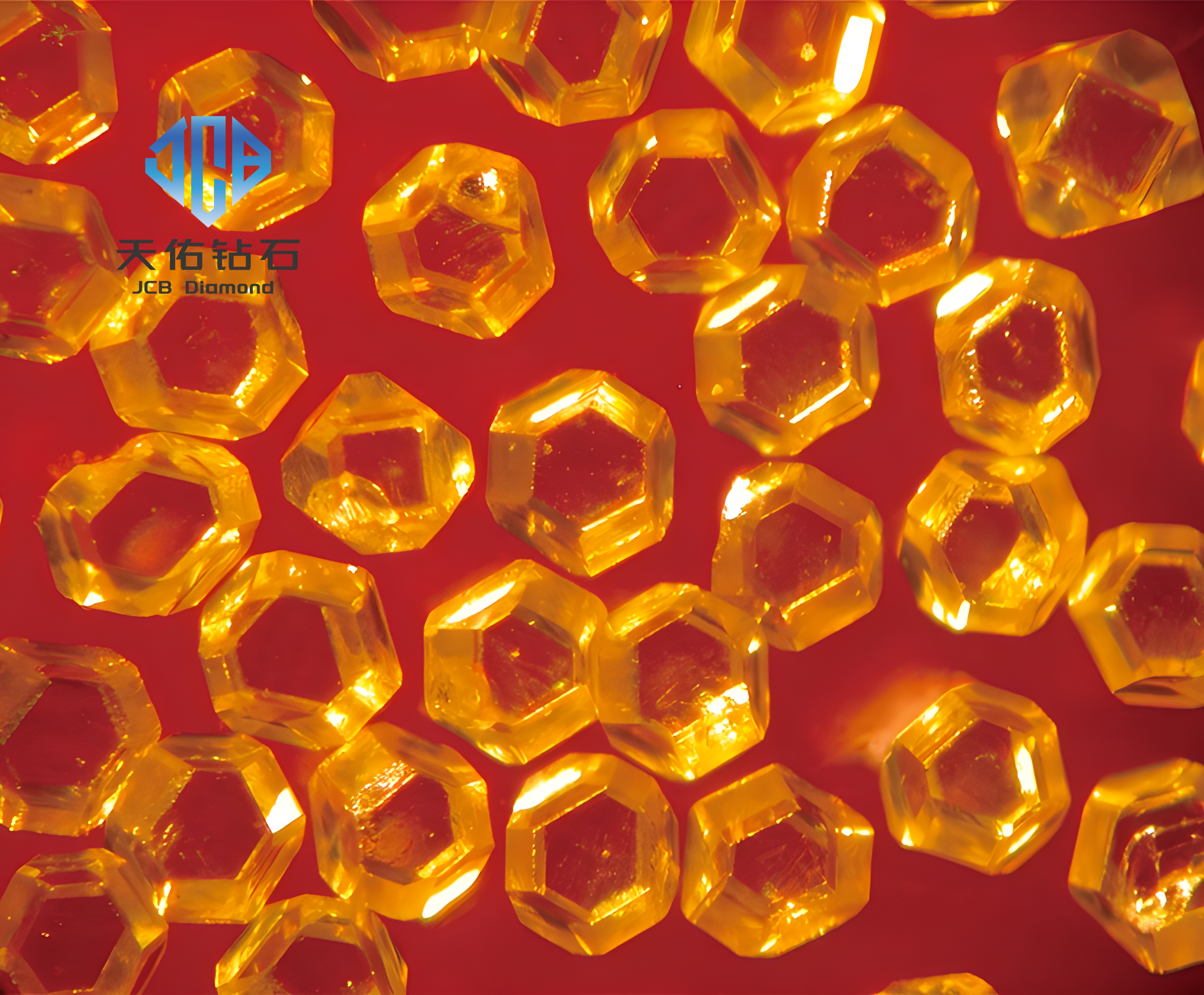

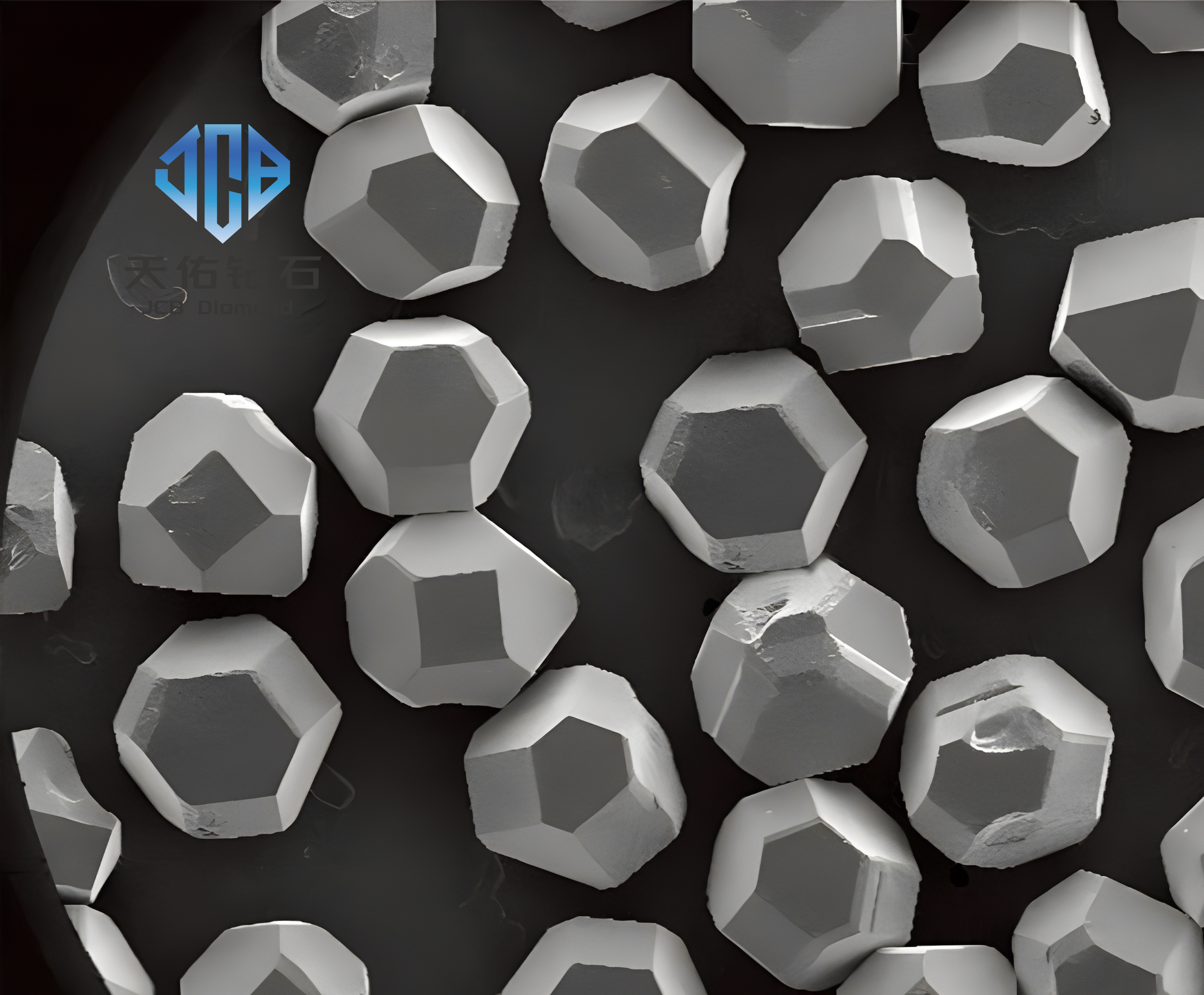

High Pressure and High Temperature Method (HPHT)

Principle: Under high pressure and high temperature conditions, carbon source materials such as graphite are transformed into diamond with the help of a catalyst.

Process: Graphite and a catalyst (such as iron, nickel, etc.) are placed in a high-pressure and high-temperature reaction chamber. By heating and pressurizing, the inside of the reaction chamber reaches a high-pressure and high-temperature state. Under these conditions, the carbon atoms in the graphite are rearranged to form diamond crystals. After the reaction, the catalyst is removed by chemical treatment and other methods to obtain synthetic diamond rough materials.

Characteristics: The produced diamond particles are relatively large and of high quality, but the production cost is high and the equipment is complex.

Chemical Vapor Deposition Method (CVD)

Principle: Using carbon-containing gases to deposit diamond films on a substrate under certain conditions, and then manufacturing diamond particles from the diamond films by mechanical processing and other methods.

Process: A mixture of carbon-containing gases (such as methane, acetylene, etc.) and hydrogen and other gases is introduced into the reaction chamber. Under conditions such as high temperature, low pressure, and plasma, the carbon-containing gases decompose and deposit diamond films on the substrate. Then, by mechanical processing and other methods, diamond particles are manufactured from the diamond films.

Characteristics: High-quality diamond particles can be produced, and the production cost is relatively low and the equipment is simple. However, the upshot is that the production speed is slow and the particle size is relatively small.

III. Application Areas of Synthetic Diamond Rough Materials

Stone Processing

Synthetic diamond rough materials can be used to manufacture stone-cutting saw blades, grinding tools and other tools, which can quickly and efficiently cut and polish various stones, improving processing efficiency and quality.

Mining

Synthetic diamond rough materials can be used to manufacture mining drill bits, cutting tools and other tools, which can drill into and cut hard rock formations, improving mining efficiency and safety.

Machining

Synthetic diamond rough materials can be used to manufacture cutting tools, grinding wheels and other tools, which can process various high-hardness materials such as cemented carbide and ceramics, improving processing precision and surface quality.

Electronic Industry

Synthetic diamond rough materials can be used to manufacture heat sinks for electronic devices, cutting tools for semiconductor materials and other tools, which can improve the heat dissipation performance and processing precision of electronic devices.

Jewelry

Synthetic diamond rough materials can be refined and polished to make various jewelry items such as diamond rings and necklaces. Since the price of synthetic diamonds is relatively low and their quality and appearance are similar to those of natural diamonds, they have a certain competitiveness in the jewelry market.