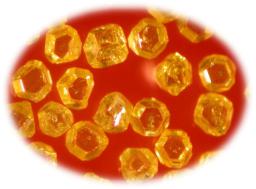

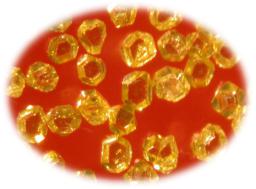

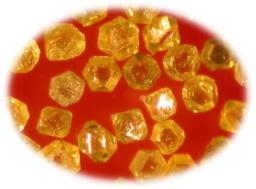

JCB JSD series is synthetic mesh diamonds saw grade, refers to the grit size of diamond from 20/25 to 50/60. This series of products are golden-yellow crystals with complete and hexahedral structure, low impurity content, good translucency, outstanding static strength, impact toughness and thermal stability. The JSD series diamonds are mainly used in the manufacture of diamond saw blades, diamond rope saws, diamond thin-wall drills, diamond grinding blocks, diamond rollers, geological drilling tools and brazing tools, etc. They are widely used in the industries of stone processing, cutting of reinforced concrete, construction of road and bridge, glass processing, oil and gas drilling, and mechanical processing.

| JSD90 Features: Complete and regular hexoctahedral crystal structure, almost no impurities within the crystal, extremely high static strength (Newton), impact toughness (TI), and thermal stability (TTI). Comprehensive performance meets international standards, with excellent wear resistance. Applications: Suitable for cutting tools, drilling tools, and brazing tools under extremely high working intensity conditions, such as cutting and drilling high-strength reinforced concrete, asphalt pavement, and extremely hard granite (F=20), as well as high-performance geological engineering drill bits. |

| JSD80 Features: Complete and regular hexoctahedral crystal structure, very few impurities within the crystal, high static strength (Newton), impact toughness (TI), and thermal stability (TTI), with excellent wear resistance. Applications: Suitable for cutting tools, drilling tools, brazing tools, and electroplating tools under high working intensity conditions, such as cutting and drilling reinforced concrete, hard granite (F=15), and high-hardness ceramic materials, as well as engineering drill bits. |

| JSD70 Features: Relatively complete hexoctahedral crystal structure, few impurities within the crystal, relatively high static strength (Newton), impact toughness (TI), and thermal stability (TTI), with good wear resistance. Applications: Suitable for cutting tools, drilling tools, brazing tools, and electroplating tools under relatively high working intensity conditions, such as cutting and drilling concrete, hard granite (F=10), high-grade tiles, and high-hardness refractory materials, as well as heavy-duty grinding tools and medium-to-high-load electroplating brazing tools. |

| JSD60 Features: Relatively complete hexoctahedral crystal structure, relatively few impurities within the crystal, moderate static strength (Newton), impact toughness (TI), and thermal stability (TTI), with a balance of wear resistance and sharpness. Applications: Suitable for high-speed cutting and drilling under medium working intensity conditions, such as cutting and drilling non-reinforced cement pavement, hard marble, low-hardness granite (F=8), large quantities of building materials, refractory materials, and non-ferrous metal materials, as well as heavy-duty grinding tools and medium-load electroplating brazing tools. |

| JSD50 Features: Relatively regular hexoctahedral crystal structure, moderate impurities within the crystal, average static strength (Newton), impact toughness (TI), and thermal stability (TTI), with moderate wear resistance and good sharpness. Applications: Suitable for high-speed cutting and drilling under low-to-medium working intensity conditions, such as cutting and drilling soft marble and sandstone (F=6-5), glass, ceramics, and batch building materials, as well as medium-load grinding tools and low-to-medium electroplating tools. |

| JSD40 Features: 90-95% regular crystal structure, moderate impurities within the crystal, relatively low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with average wear resistance and excellent sharpness. Applications: Suitable for high-speed cutting and drilling under low working intensity conditions, such as small-diameter free-cutting drilling tools, as well as medium-to-low-load grinding tools and low-load electroplating tools. |

| JSD30 Features: 85% regular crystal structure, more impurities within the crystal compared to JSD40, relatively low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with poor wear resistance and excellent sharpness. Applications: Suitable for small-diameter free-cutting tools and drilling tools with excellent sharpness, such as cutting and drilling gemstones, jade, crystal, and other high-brittle materials, as well as small batches of stone, glass, and tiles, as well as medium-to-low-load grinding tools and low-load electroplating tools. |

| JSD20 Features: 70% regular crystal structure, relatively high impurities within the crystal, rough surface, low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with poor wear resistance and extremely high sharpness. Applications: Suitable for small-diameter free-cutting tools and drilling tools with excellent sharpness, medium-to-high-load ceramic bond tools, low-load metal bond grinding tools, and extremely sharp electroplating tools. Used for processing hard alloys, magnetic materials, glass, tiles, crystal, gemstones, and other brittle materials. Can also be used in combination with high-grade diamonds to adjust tool sharpness. |

| JSD10 Features: 50% regular crystal structure, high impurities within the crystal, rough surface, very low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with very poor wear resistance, extremely high sharpness, and good self-sharpening properties. Applications: Suitable for medium-to-high-load resin bond tools, medium-to-low-load ceramic bond tools, low-load metal bond grinding tools, and extremely sharp electroplating tools. Used for processing hard alloys, magnetic materials, glass, tiles, crystal, gemstones, and other brittle materials. Can also be used in combination with high-grade diamonds to adjust tool sharpness. |

| Grade/Size | JSD10 | JSD20 | JSD30 | JSD40 | JSD50 | JSD60 | JSD70 | JSD80 | JSD90 |

| 20/25 | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 25/30 | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 30/35 | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 35/40 | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 40/45 | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 45/50 | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 50/60 | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| JCB GB/T6406-1995 | United States ANSI US Mesh # | European Federation of Producers of Abrasives FEPA D | International Standardization Organization ISO | Russia GOST9206-80 |

| 20/25 | 20/25 | D851 | 850/710 | 850/710 |

| 25/30 | 25/30 | D711 | 710/600 | 710/600 |

| 30/35 | 30/35 | D601 | 600/500 | 630/500 |

| 35/40 | 35/40 | D501 | 500/425 | 500/400 |

| 40/45 | 40/45 | D426 | 425/355 | 400/315 |

| 45/50 | 45/50 | D356 | 355/300 | 400/315 |

| 50/60 | 50/60 | D301 | 300/250 | 315/250 |