The JCB PCBN blank are formed by sintering mixed high-quality, high-strength CBN Micro-powder with various bonding agents onto a carbide substrate under ultra-high temperature and pressure conditions. Their service life is 10 to 25 times that of carbide tools. JCB PCBN composite sheets are widely used in cutting processes across industries such as military, automotive, metallurgical rollers, bearings, and molds.

The PCBN blank by our company exhibit extremely high hardness, excellent high-temperature resistance, and strong chemical inertness. They do not react chemically with ferrous metals even at high temperatures, combining the high hardness, wear resistance, and high-temperature resistance of CBN with the impact toughness of carbide. Their service life is 10 to 25 times that of carbide tools. They are primarily used for machining various types of cast iron, hardened steel, powder metallurgy, and other difficult-to-machine materials. They are widely applied in cutting processes across industries such as military, automotive, metallurgical rollers, bearings, and molds.

| brand | Form of structure | Processing method | Product Features | Applicable Processing Objects |

| PCBN9100T | Combined type | Rediscontinuous processing | 1) Suitable for the rough machining of all kinds of cast iron materials; 2) Suitable for the rough processing of high manganese steel and other materials; | Metallurgical roll, air conditioning compressor, slurry pump, mining machinery, etc. |

| PCBN9200T | Combined type | Intermittent processing Continuous processing | 1)Suitable for semi-finishing and finishing of all kinds of cast iron materials; 2)Suitable for semi-finishing of quenching steel and high-temperature alloy materials; | Air-conditioning compressor, bearing, crankshaft, gear, auto parts, etc. |

| PCBN9300T | Combined type | Broken processing | 1)Suitable for quenching steel work-piece: such as bearing steel, tool steel, mold steel, high-speed steel rough machining and semi-finishing machining; | Wind power generation, machine tools, gear, etc. |

| PCBN9400T | Combined type | Intermittent processing Continuous processing | Suitable for heat-resistant steel work-piece and quenching steel work-piece: such as bearing steel, tool steel, die steel, high-speed steel semi-finishing and finishing; | Wind power generation, machine tools, gear, etc. |

| PCBN9500T | Combined type | Intermittent processing Continuous processing | 1)Suitable for all kinds of powder metallurgy materials coarse finishing; 2)Suitable for rough and finishingof various cast iron materials | Powder metallurgy, molds,automotive parts, bearings,crankshafts, gears, etc.. |

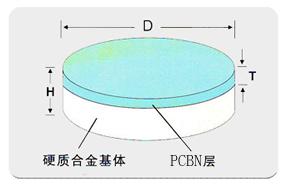

| Product series | Diameter D, mm | Total thickness H, mm (+/-0.05) | CBN layer thickness T, mm (+/-0.1) |

| PCBN9100T | ф45/ф55 | 1.6/2.0/3.2/4.5 | 1.0 |

| PCBN9200T | ф45/ф55 | 1.6/2.0/3.2/4.5 | 1.0 |

| PCBN9300T | ф45/ф55 | 1.6/2.0/3.2/4.5 | 1.0 |

| PCBN9400T | ф45/ф55 | 1.6/2.0/3.2/4.5 | 1.0 |

| PCBN9500T | ф45/ф55 | 1.6/2.0/3.2/4.5 | 1.0 |