Detail

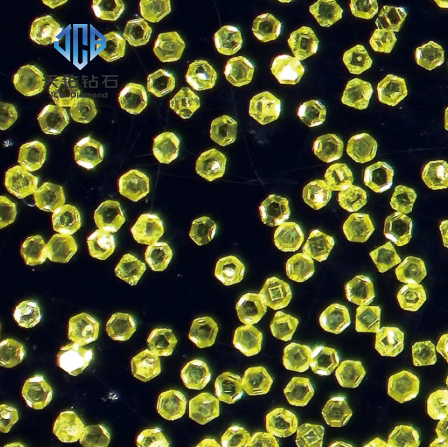

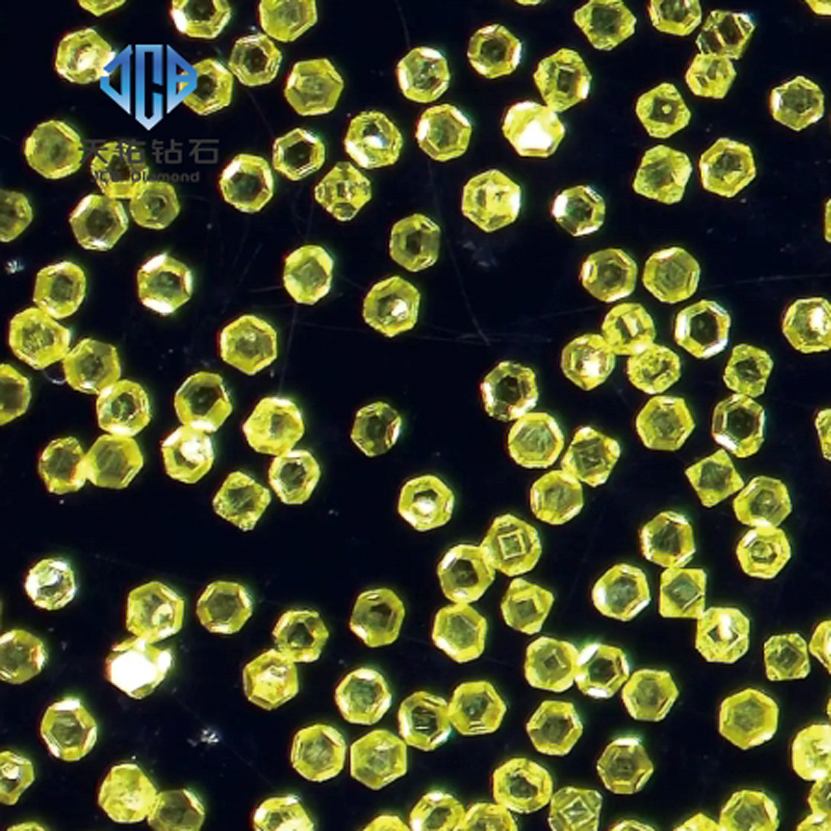

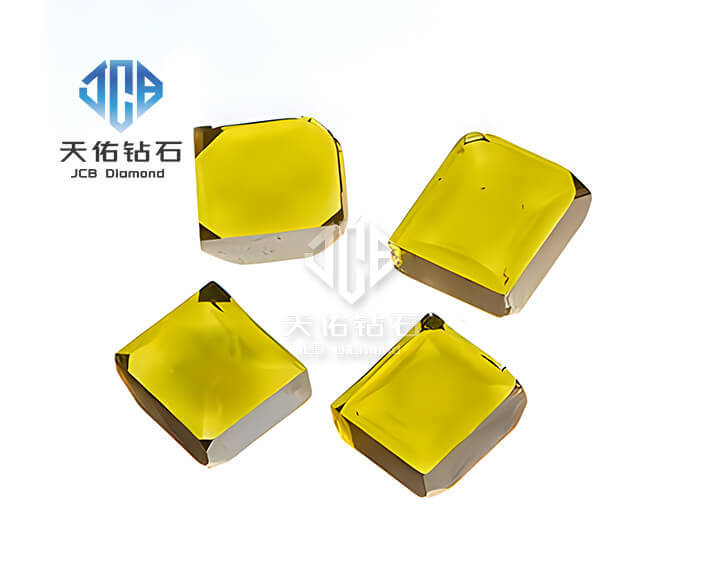

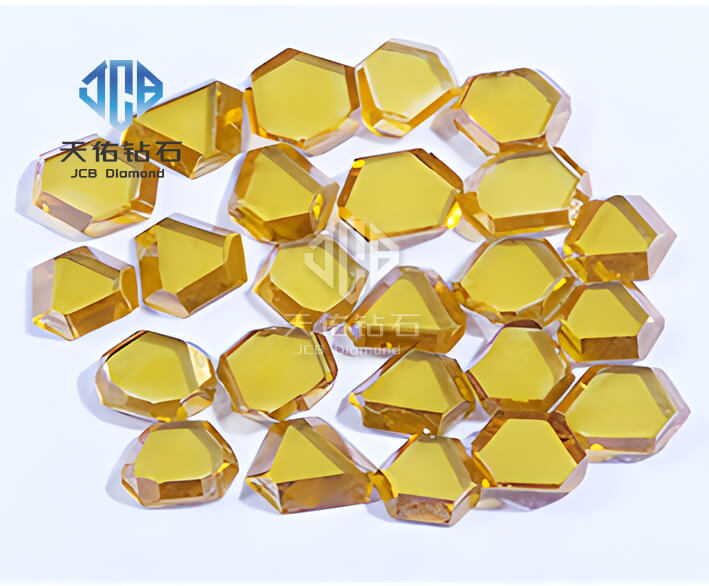

The company adopts special production processes, and the produced diamond for thermal conductivity has extremely low internal impurities (non-diamond carbon, nitrogen impurities, etc.), good thermal stability, few lattice defects, high hardness, and good wear resistance, among other excellent characteristics. The surface has undergone high-purity treatment, improving the thermal boundary, which can achieve very low interfacial thermal resistance and high thermal conductivity, making it suitable for the production of high-end thermal interface materials.

Characteristic: Extremely low internal impurity content, excellent thermal stability, minimal lattice defects, high hardness, and outstanding wear resistance. Its surface is treated with high-purity purification to enhance thermal interface performance, achieving low interfacial thermal resistance and high thermal conductivity and ideal for advanced thermal management applications.

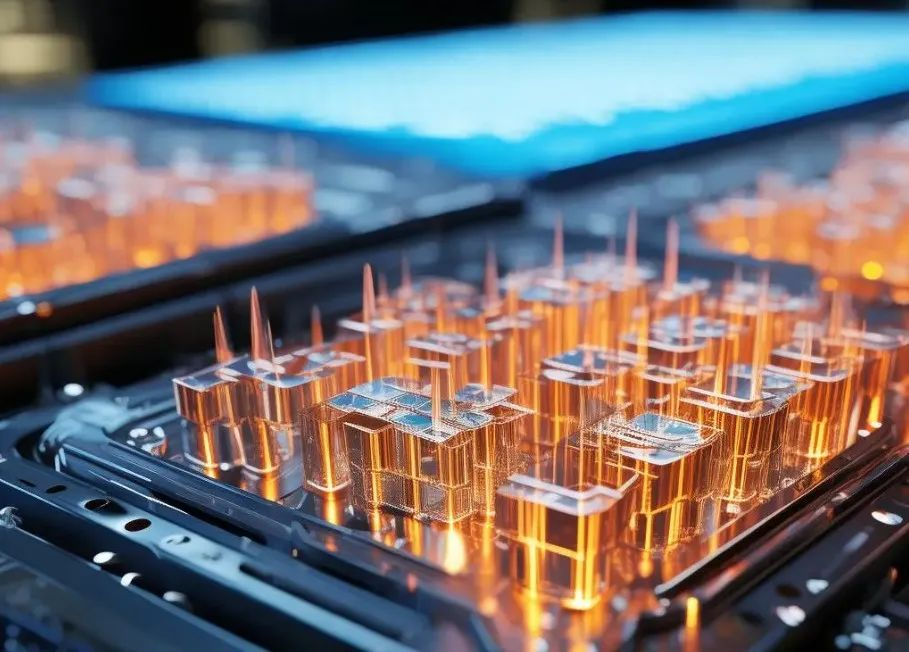

Application: Suitable for high-end thermal interface materials (TIMs) in electronics, optoelectronics, and high-power devices, where efficient heat dissipation is critical.

Thermal conductive diamond powder is widely used across industries to enhance heat dissipation and improve the reliability of thermal management solutions. Its excellent thermal conductivity, electrical insulation, and compatibility with diverse materials make it an ideal choice for electronic packaging, composites, and advanced thermal interface materials.

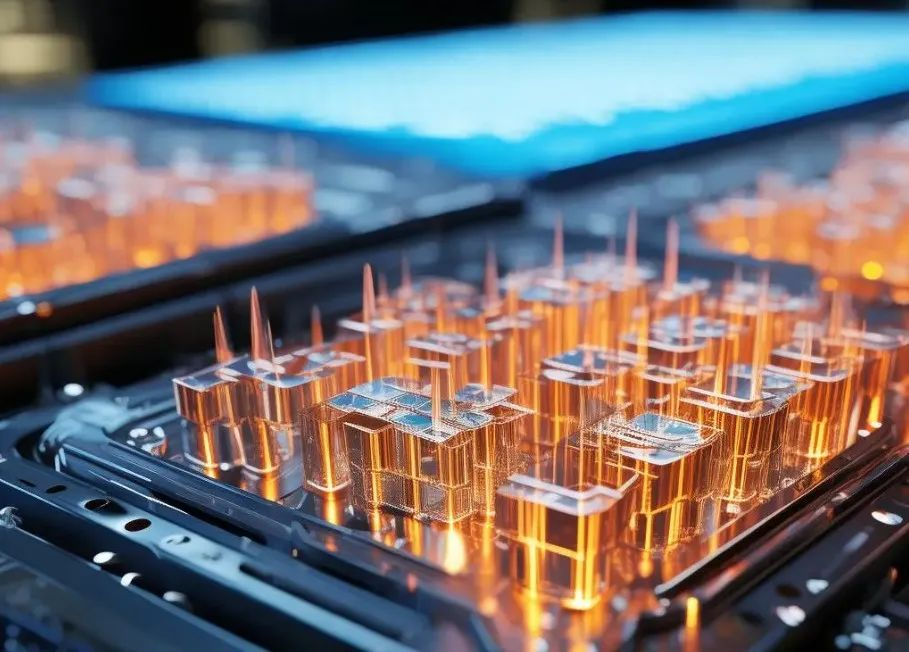

Thermal Interface Materials (TIMs): Used as a high-performance filler in thermal grease, pads, and adhesives to enhance heat transfer and maintain electrical insulation in electronic devices and power modules.

Electronic Packaging: Improves thermal conductivity of encapsulants, underfills, and potting compounds, helping dissipate heat from semiconductors and extend component lifespan.

Polymer and Resin Composites: Blended into plastics, epoxies, and composites to create lightweight materials with excellent thermal conductivity for housings, connectors, and heat spreaders.

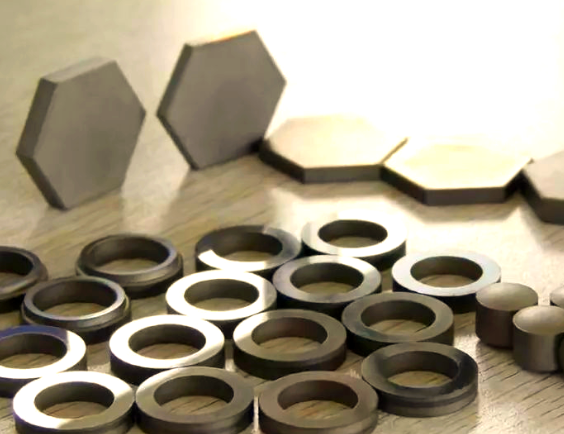

Ceramic and Metal Matrix Composites: Incorporated into ceramic or metal matrices to form high-thermal-conductivity structural parts used in aerospace, automotive, and high-power electronics.

Advanced Thermal Management Systems: Applied in customised solutions for high-reliability thermal management applications, such as LED cooling, communication equipment, and energy storage systems.

With high purity, uniform particle morphology, and excellent compatibility with diverse matrix materials, JCB’s thermal conductive diamond powder helps manufacturers create efficient, reliable thermal management solutions across a wide range of industries.

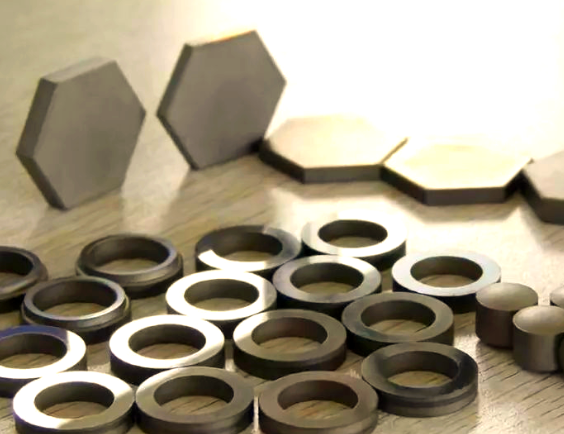

The grades are divided into JCB-AGT, JCB-AGP, JCB-AGH, JCB-AGG, with particle sizes ranging from 30 to 540 μm.

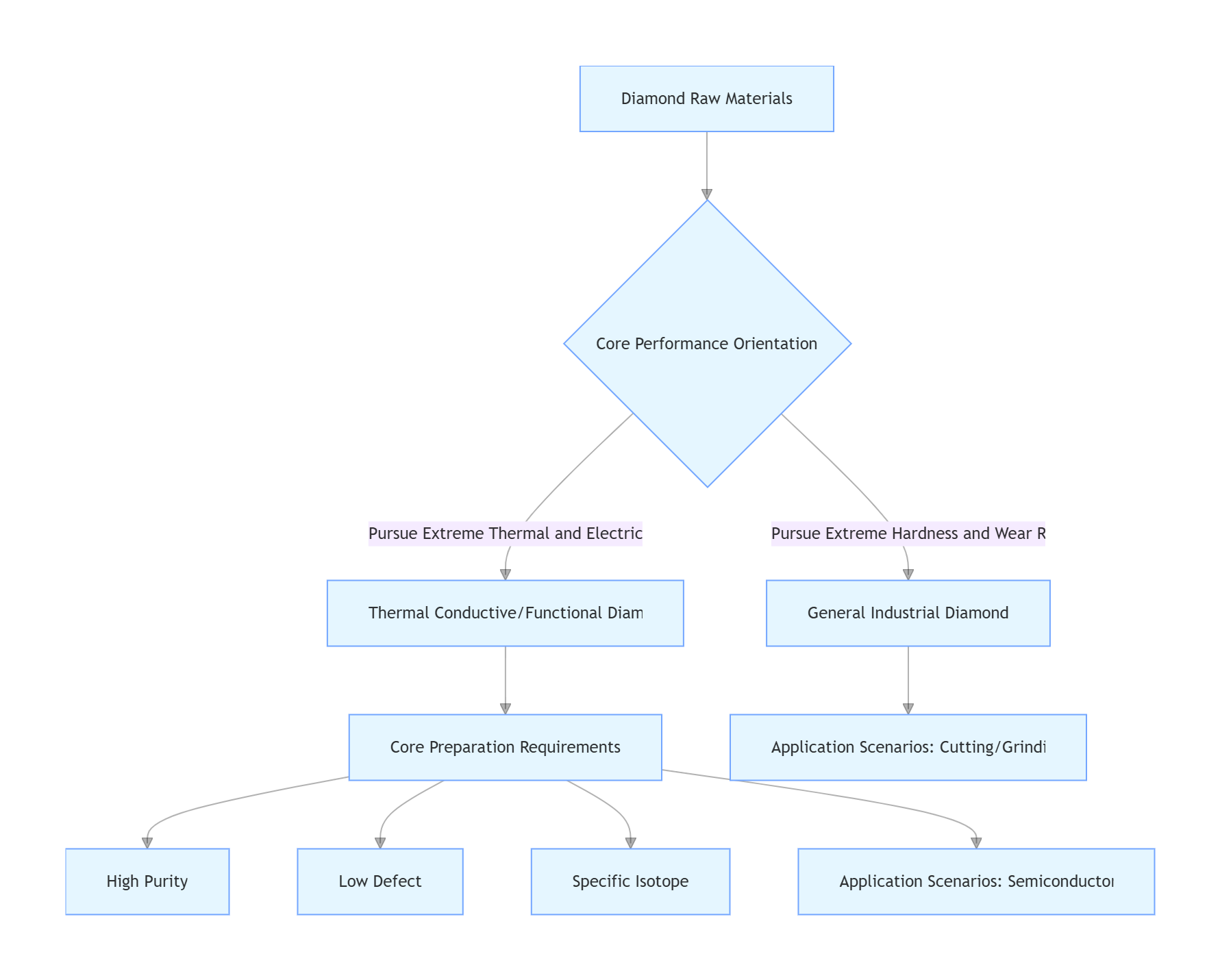

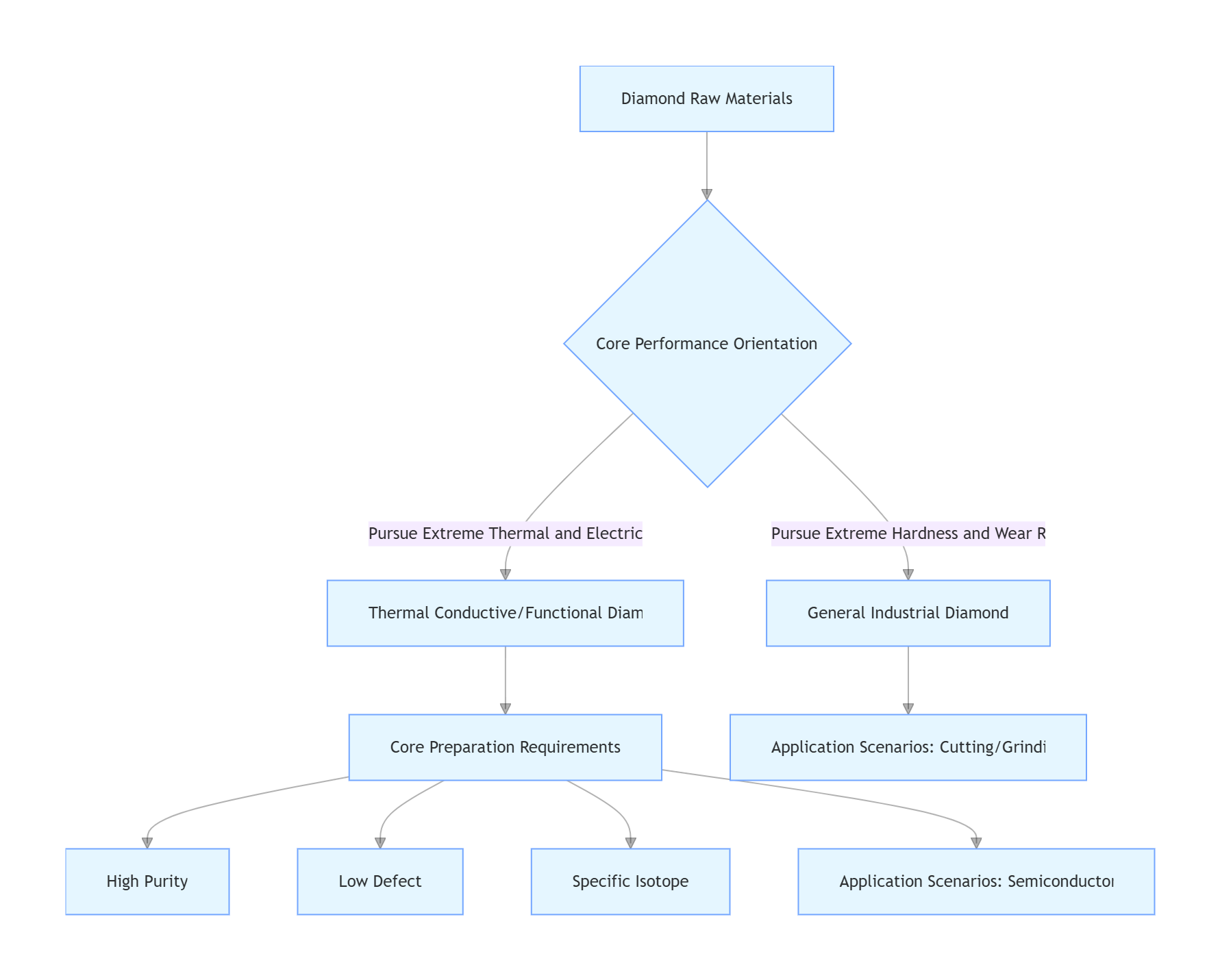

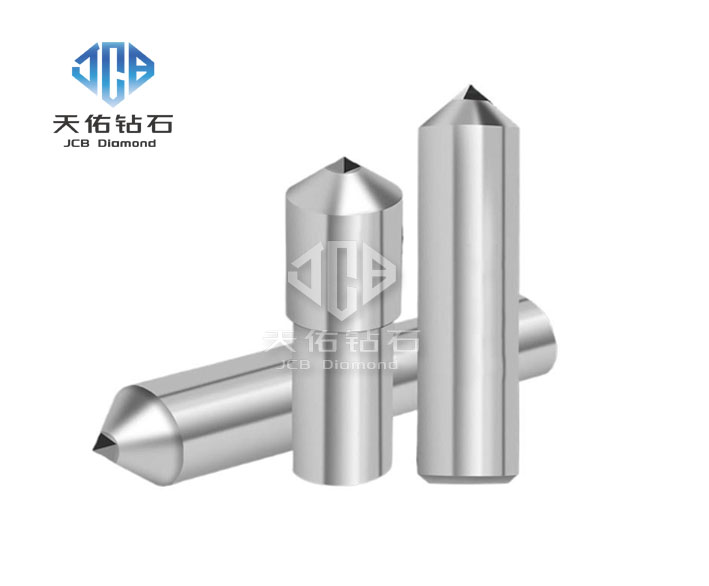

The difference between the thermal conductive diamond and general industrial diamond.