PDC Cutters for Oil & Gas uses feature higher-grade diamond-specific micro-powder and hard alloy matrix. Utilizing unique assembly methods and advanced sintering processes, the diamond micro-powder and Tungsten Carbide matrix are sintered under ultra-high temperature and pressure conditions. This results in composite inserts that achieve international advanced levels in wear resistance, heat resistance, and impact resistance. The JCB PDC Cutters for Oil & Gas are specifically designed and manufactured for oil and gas drill bits, suitable for ultra-deep drilling in complex formations, hard formations, heterogeneous formations, and highly abrasive formations. The JCB offers PDC Cutters products in standard specifications such as 08,09,10,13,16,19, and 25, as well as various custom specifications.

The JCB PDC cutters for oil and gas utilize higher-grade diamond-specific Micro-powder and carbide substrates. Through unique assembly methods and advanced sintering processes, the diamond Micro-powder and carbide substrate are sintered under ultra-high temperature and pressure conditions, achieving international advanced levels in various physical and mechanical properties such as wear resistance, heat resistance, and impact resistance. JCB PDC Cutters for Oil & Gas are specifically designed and manufactured for oil and gas drill bits, suitable for ultra-deep drilling in complex formations, hard formations, heterogeneous formations, and highly abrasive formations. JCB offers PDC Cutters products in standard specifications such as 08, 09, 10, 13, 16, 19, 25, as well as various custom specifications.

| Product series | Product Features | Scope of application |

| PDC OG-E | Exhibits excellent wear resistance, heat resistance, and relatively high impact resistance. | Suitable for drilling in soft to medium-hard formations. |

| PDC OG-H | Exhibits excellent wear resistance, heat resistance, and relatively high impact resistance. | Suitable for ultra-deep drilling in complex formations, hard formations, heterogeneous formations, and highly abrasive formations. |

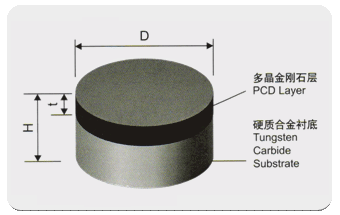

| Model | 2513 | 2508 | 1919 | 1916 | 1913 | 1908 | 1619 | 1616 | 1613 | 1610 | 1608 |

| D(mm)(±0.03) | 25.40 | 25.40 | 19.05 | 19.05 | 19.05 | 19.05 | 16.05 | 16.05 | 16.05 | 16.05 | 16.05 |

| H(mm)(±0.10) | 13.20 | 8.00 | 19.00 | 16.31 | 13.20 | 8.00 | 19.00 | 16.00 | 13.20 | 10.00 | 8.00 |

| t(mm) | 2.0-4.0 | ||||||||||

| Model | 1316 | 1313 | 1308 | 1304 | 1303 | 1011 | 1008 | 1004 | 0808 | 0803 | 0608 |

| D(mm)(±0.03) | 13.44 | 13.44 | 13.44 | 13.33 | 13.33 | 10.00 | 10.00 | 10.00 | 8.20 | 8.20 | 6.00 |

| H(mm)(±0.10) | 16.00 | 13.20 | 8.00 | 4.50 | 3.53 | 11.00 | 8.00 | 4.50 | 8.00 | 3.53 | 8.00 |

| t(mm) | 2.0-4.0 | ||||||||||