The JCB PDC Cutters for Stone are sintered from diamond Micro-powder and carbide substrates under high temperature and pressure conditions. These composite sheets feature high hardness, strong wear resistance, and cost-effectiveness, making them ideal for cutting and grinding highly abrasive stone materials and polishing concrete floors. JCB offers PDC Cutters products in standard specifications such as 08, 09, 10, 13, 16, 19, as well as various custom specifications.

Our company produces PDC Cutters for Stone using diamond Micro-powder as raw material. The diamond Micro-powder and carbide substrate are sintered under high temperature and pressure conditions, resulting in products with high hardness, strong wear resistance, and cost-effectiveness. These sheets are primarily used for cutting and grinding highly abrasive stone materials and polishing concrete floors.

| Product series | Product characteristics | Scope of application | ||

Diamond layer thickness (mm) | Wear ratio (X10000) | Impact toughness (J) | ||

| PDC-ST1 | 1.0-1.2 | 25 | 300 | Used for cutting and grinding highly abrasive stone materials and polishing concrete floors. |

| PDC-ST2 | 1.2-1.5 | 30 | 400 | Used for cutting and grinding highly abrasive stone materials and polishing concrete floors. |

| PDC-ST3 | 1.6-1.8 | 40 | 600 | Used for cutting and grinding highly abrasive stone materials and polishing concrete floors. |

| PDC-ST4 | 1.8-2.0 | 60 | 800 | Used for cutting and grinding highly abrasive stone materials and polishing concrete floors. |

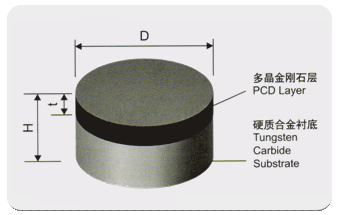

| Model | 2513 | 2508 | 1919 | 1916 | 1913 | 1908 | 1619 | 1616 | 1613 | 1610 | 1608 |

| D(mm)(±0.03) | 25.40 | 25.40 | 19.05 | 19.05 | 19.05 | 19.05 | 15.88 | 15.88 | 15.88 | 15.88 | 16.00 |

| H(mm)(±0.10) | 13.20 | 8.00 | 19.00 | 16.31 | 13.20 | 8.00 | 19.00 | 16.00 | 13.20 | 10.00 | 8.00 |

| t(mm) | 1.0-3.0 | ||||||||||

| Model | 1008 | 1004 | 0808 | 0803 | 0608 | ||||||

| D(mm)(±0.03) | 13.44 | 13.44 | 13.44 | 13.30 | 13.30 | 10.00 | 10.00 | 10.00 | 8.20 | 8.20 | 6.00 |

| H(mm)(±0.10) | 16.00 | 13.20 | 8.00 | 4.50 | 3.53 | 11.00 | 8.00 | 4.50 | 8.00 | 3.53 | 8.00 |

| t(mm) | 1.0-3.0 | ||||||||||