Detail

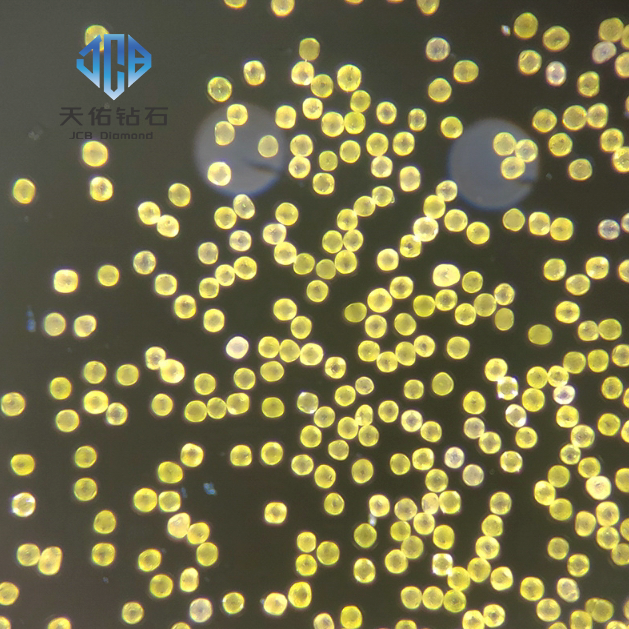

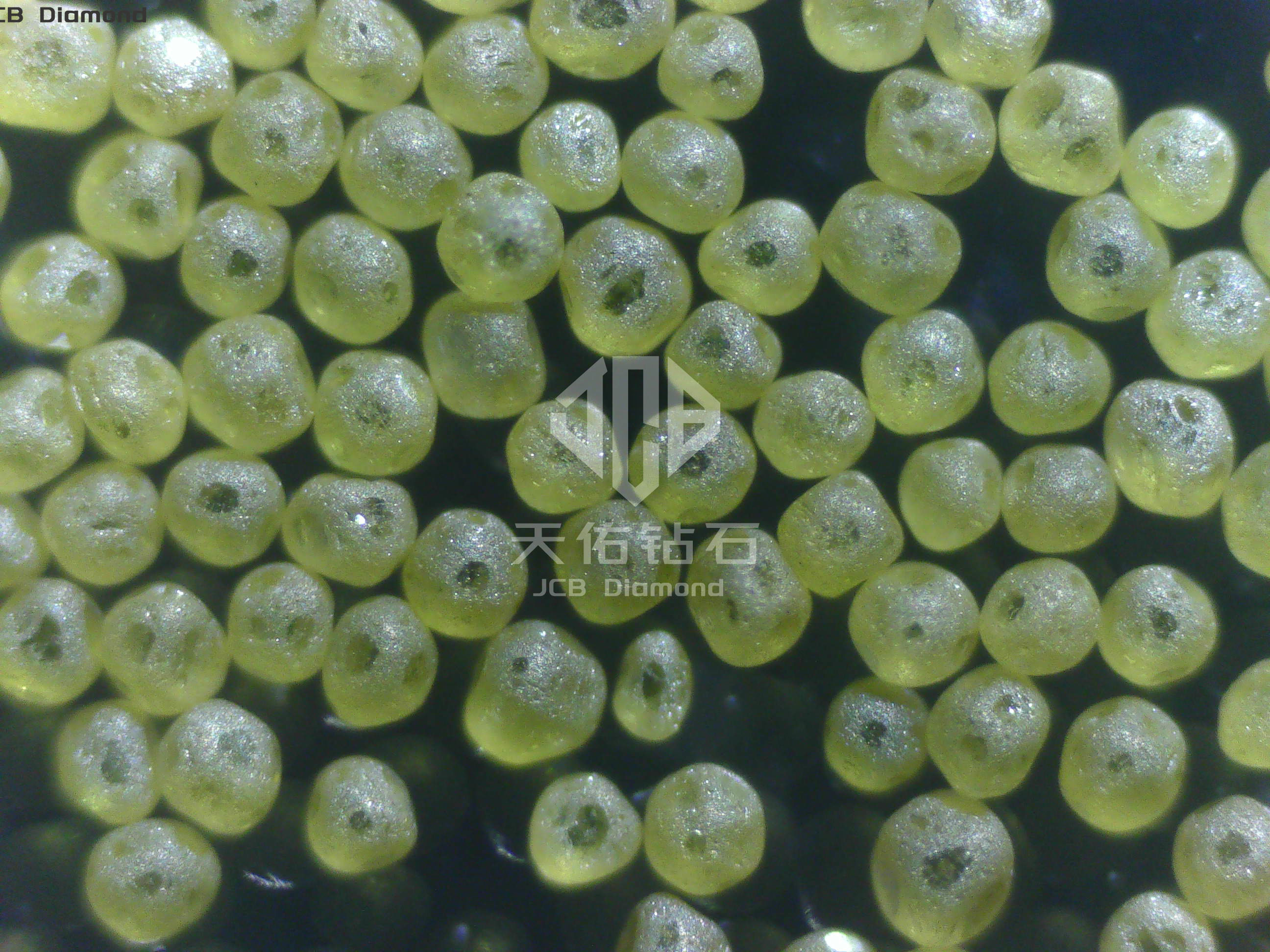

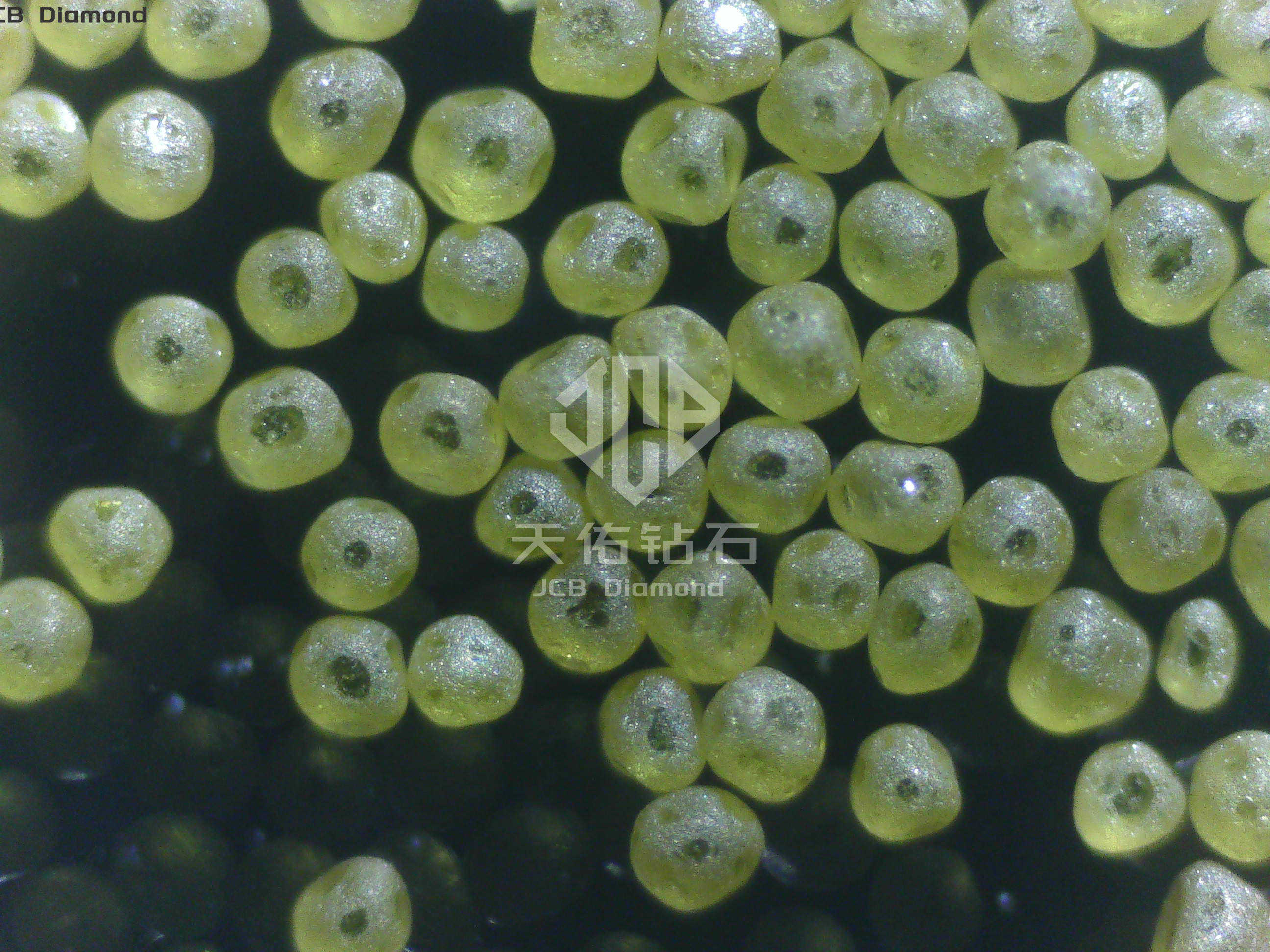

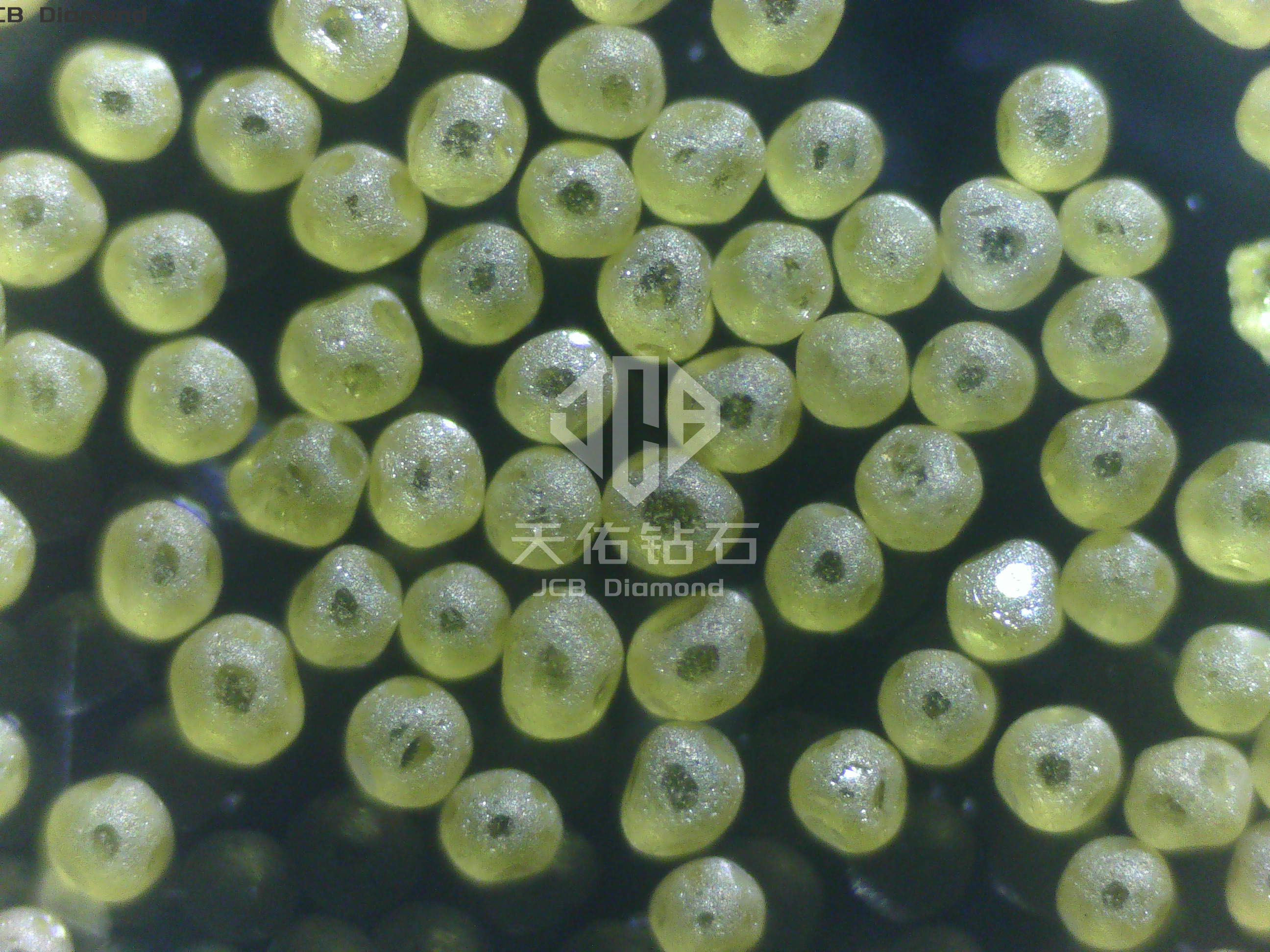

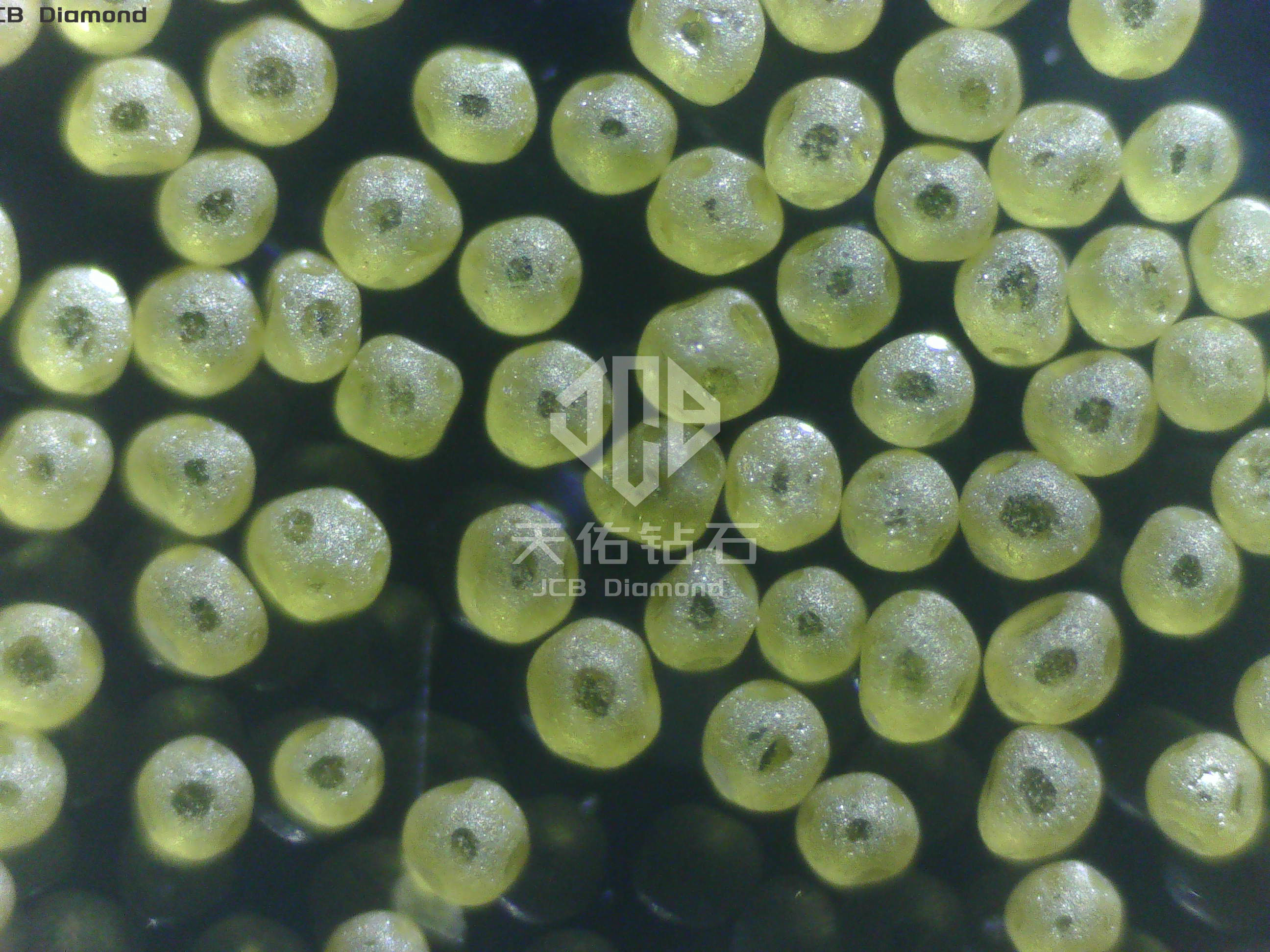

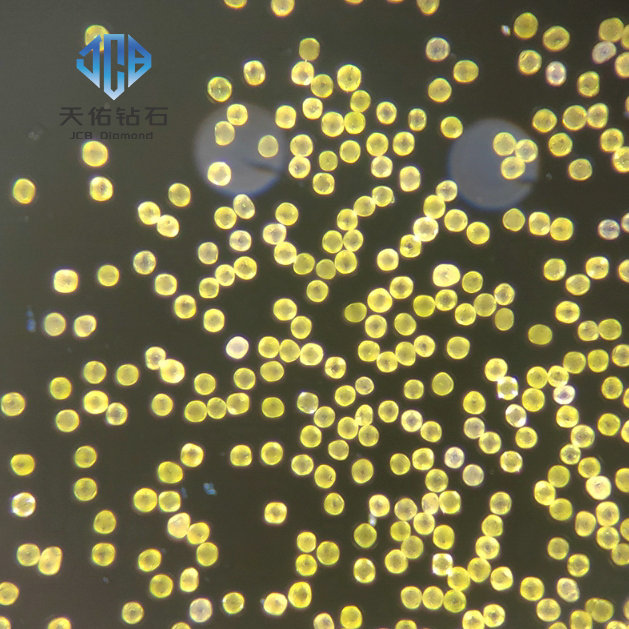

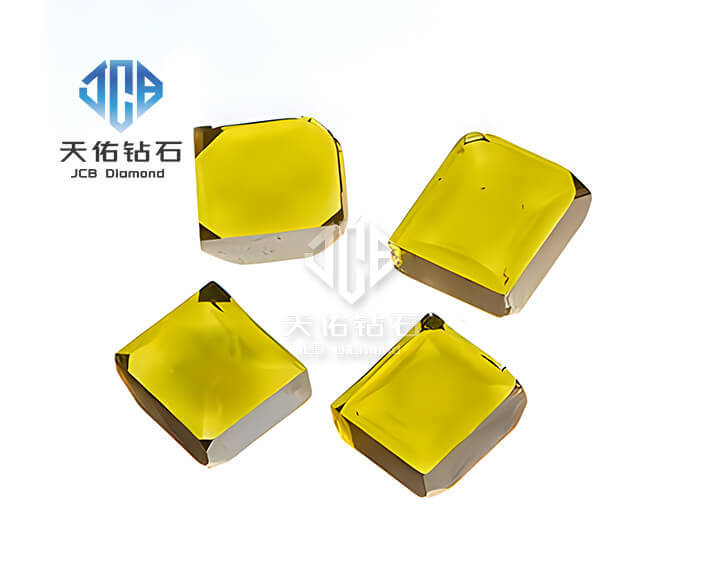

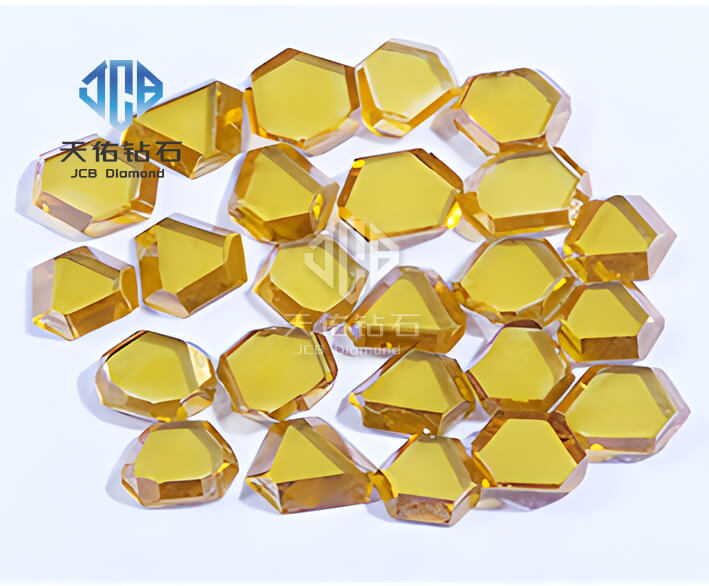

Spherical diamond has a regular spherical or nearly spherical shape, with a high specific surface area, good adsorption capacity, and ease of filling. In composite materials, spherical diamonds can be better dispersed in the matrix, reducing the gaps between particles and the interfacial thermal resistance, thereby improving the overall thermal conductivity. In addition, the spherical shape helps to increase the contact area and bonding strength between the diamond and the matrix, further facilitating heat transfer.

Characteristic: Spherical diamond features a regular spherical or near-spherical shape with high specific surface area. It offers good adsorption, easy filling, and uniform dispersion in composites, reducing voids and interfacial thermal resistance. The shape also improves contact area and bonding strength with the matrix, enhancing overall heat transfer.

Application:Widely used as a thermal management material in diamond/copper and diamond/aluminium heat sinks to boost thermal conductivity. Also serves as an additive or filler in high thermal conductivity epoxy, silicone, and resin composites.

Size: 20µm~600µm

Application: Suitable for high-end thermal interface materials (TIMs) in electronics, optical electronics, and high-power devices, where efficient heat dissipation is critical.

Thermal conductive diamond powder is widely used across industries to enhance heat dissipation and improve the reliability of thermal management solutions. Its excellent thermal conductivity, electrical insulation, and compatibility with diverse materials make it an ideal choice for electronic packaging, composites, and advanced thermal interface materials.

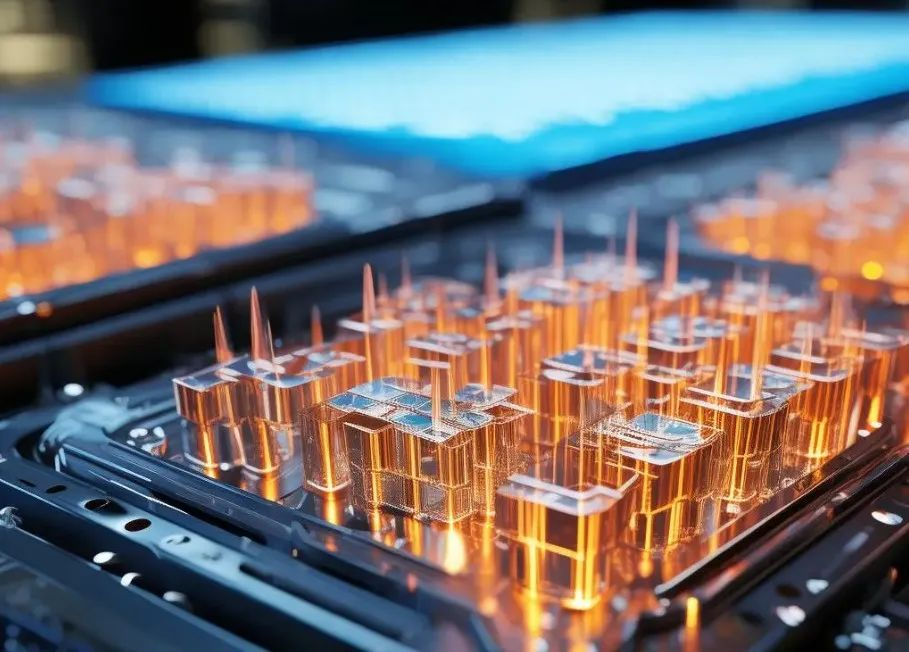

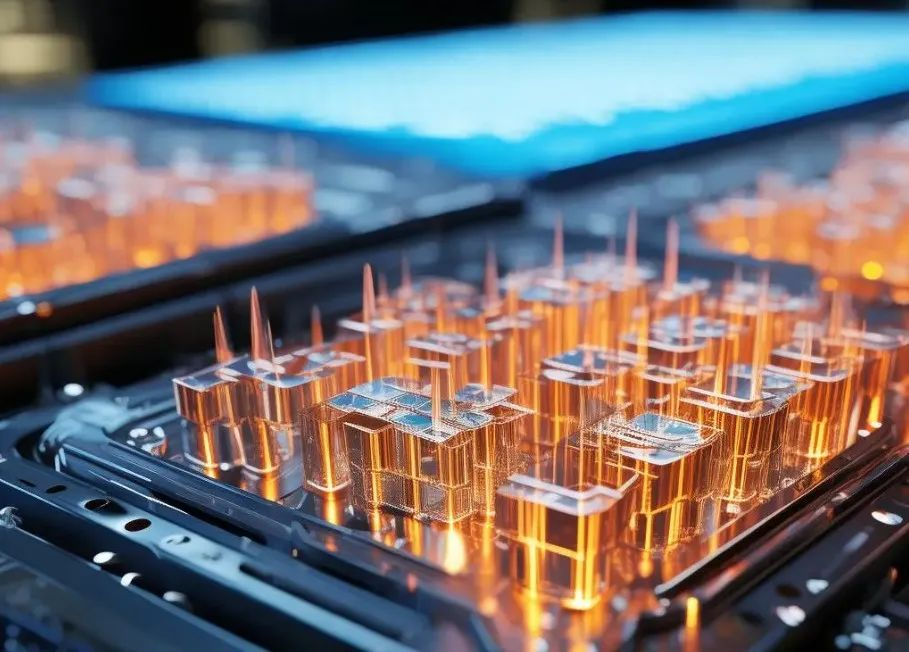

Thermal Interface Materials (TIMs): Used as a high-performance filler in thermal grease, pads, and adhesives to enhance heat transfer and maintain electrical insulation in electronic devices and power modules.

Electronic Packaging: Improves thermal conductivity of encapsulants, underfills, and potting compounds, helping dissipate heat from semiconductors and extend component lifespan.

Polymer and Resin Composites: Blended into plastics, epoxies, and composites to create lightweight materials with excellent thermal conductivity for housings, connectors, and heat spreaders.

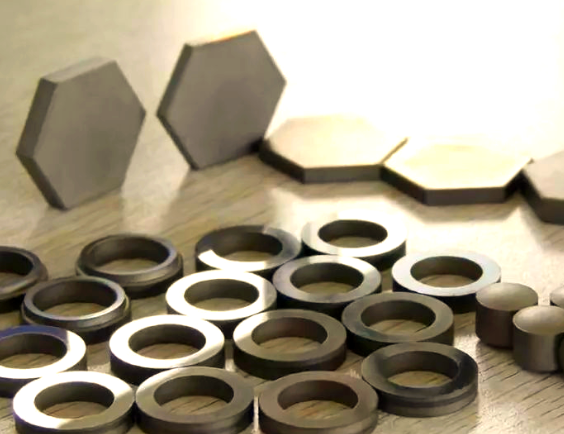

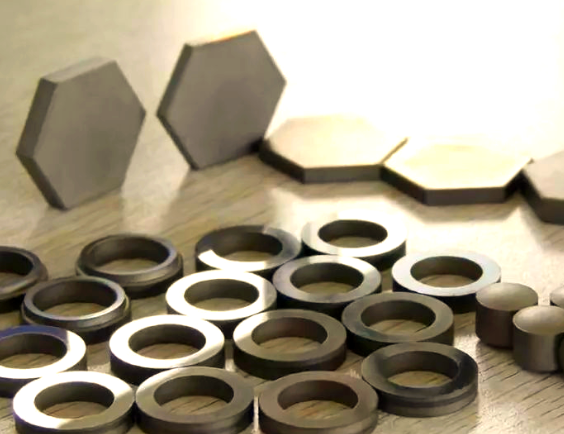

Ceramic and Metal Matrix Composites: Incorporated into ceramic or metal matrices to form high-thermal-conductivity structural parts used in aerospace, automotive, and high-power electronics.

Advanced Thermal Management Systems: Applied in customised solutions for high-reliability thermal management applications, such as LED cooling, communication equipment, and energy storage systems.

With high purity, uniform particle morphology, and excellent compatibility with diverse matrix materials, JCB’s thermal conductive diamond powder helps manufacturers create efficient, reliable thermal management solutions across a wide range of industries.