The JCB JGDM series diamond micro-powder refers to diamond particles with a particle size finer than 60/40 microns, which are produced using high-quality single crystal diamonds as raw materials and undergo processes such as crushing, shaping, purification, and classification. The JCB JGDM series diamond micro-powder boasts high hardness and excellent wear resistance, making it suitable for cutting, grinding, and polishing applications. It serves as an ideal raw material for grinding and polishing hard materials like cemented carbides, ceramics, gems, optical glass, and is widely used in industries including machinery, aerospace, optics, glass, ceramics, electronics, petroleum, geology, defense, and more. With the continuous development of technology and products, the application fields of JCB JGDM series diamond micro-powder and its products are continually expanding.

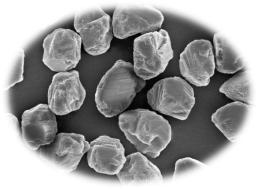

| ACM Features: Utilizes premium resin-bonded diamond JBD6(AC6) as raw material, processed through advanced manufacturing techniques including crushing, shaping, purification, and grading. The product is light gray, has a regular crystalline shape, low impurity content, low magnetism, excellent self-sharpening properties, a polycrystalline-like structure, and precise control over shape and size distribution. Applications: Suitable for the production of resin-bonded abrasives, grinding pastes, and grinding fluids, used in precision polishing of hard alloys, optical glass, and areas requiring extremely high product quality. |

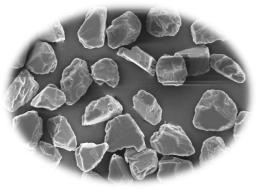

| JGDM-D Features: Made from high-quality resin-bonded diamond JRD, processed through advanced manufacturing methods involving crushing, shaping, purification, and grading. The product is light yellow-green, has a relatively regular crystal shape, low impurity content, good self-sharpening properties, and uniform size distribution. Applications: Ideal for resin-bonded, ceramic-bonded abrasives, grinding pastes, and fluids. Used in polishing gemstones, stone, ceramic tiles, glass, optical glass, and hard alloys. An economical resin diamond micro-powder with high grinding efficiency and wear resistance. |

| JGDM-C Features: A general-purpose micro-powder, made from high-quality single-crystal synthetic diamond JSD10. Processed using advanced technology, including crushing, shaping, purification, and grading. The product is light yellow, has a relatively regular crystal form, low impurity content, low magnetism, and uniform size distribution. Applications: Suited for metal-bonded, ceramic-bonded, and resin-bonded abrasives, grinding pastes, and grinding fluids. Used in polishing gemstones, glass, optical glass, ceramics, stone, PCD/PCBN, and other non-metallic materials. |

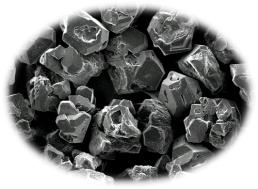

| JGDM-B Features: A high-strength powder, made from premium single-crystal diamond JSD20. Processed through advanced techniques involving crushing, shaping, purification, and grading. The product is light yellow, has a regular crystal shape, low impurity content, low magnetism, and a concentrated particle size distribution. Applications: For metal-bonded, ceramic-bonded abrasives, electroplated tools, grinding pastes, and fluids. Used in the production of precision grinding wheels for optical glass, fine grinding pellets, edge grinding wheels, precision polishing discs, sapphire precision grinding wheels for silicon materials, precision processing tools for gems and jade, and wire saws for slicing monocrystalline silicon and sapphire. |

| JGDM-A Features: A high-strength powder, made from high-strength premium single-crystal diamond JSD30. Processed through advanced manufacturing techniques including crushing, shaping, purification, and grading. The product is light yellow, has a regular crystal shape, extremely low impurity content, low magnetism, a concentrated size distribution, high strength, excellent dispersion, and wear resistance. Applications: Suitable for manufacturing metal bond tools, ceramic bond tools, and various electroplated tools, used for cutting, grinding, and polishing organic and inorganic brittle materials. Examples include wire saws for cutting mono-crystalline silicon and sapphire, precision cutting blades for gemstones and semiconductors, and precision grinding and polishing tools for mono-crystalline silicon, polycrystalline silicon, diamonds, gemstones, sapphire, quartz wafers, LED sapphire substrates, liquid crystal glass, high-precision magnetic materials, and semiconductors. |

| Grade/Size | ACM | JGDM-D | JGDM-C | JGDM-B | JGDM-A |

| 0-0.05 | Y | Y | Y | ||

| 0-0.1 | Y | Y | Y | ||

| 0-0.125 | Y | Y | Y | ||

| 0-0.2 | Y | Y | Y | Y | |

| 0-0.25 | Y | Y | Y | Y | |

| 0-0.5 | Y | Y | Y | Y | Y |

| 0-1 | Y | Y | Y | Y | Y |

| 0-2 | Y | Y | Y | Y | Y |

| 1-2 | Y | Y | Y | Y | Y |

| 1-3 | Y | Y | Y | Y | Y |

| 2-3 | Y | Y | Y | Y | Y |

| 2-4 | Y | Y | Y | Y | Y |

| 2-5 | Y | Y | Y | Y | Y |

| 3-5 | Y | Y | Y | Y | Y |

| 4-6 | Y | Y | Y | Y | Y |

| 4-8 | Y | Y | Y | Y | Y |

| 5-7 | Y | Y | Y | Y | Y |

| 5-10 | Y | Y | Y | Y | Y |

| 6-12 | Y | Y | Y | Y | Y |

| 7-10 | Y | Y | Y | Y | Y |

| 8-12 | Y | Y | Y | Y | Y |

| 8-16 | Y | Y | Y | Y | Y |

| 10-14 | Y | Y | Y | Y | Y |

| 10-20 | Y | Y | Y | Y | Y |

| 14-20 | Y | Y | Y | Y | Y |

| 12-22 | Y | Y | Y | Y | Y |

| 15-25 | Y | Y | Y | Y | Y |

| 20-28 | Y | Y | Y | Y | Y |

| 20-30 | Y | Y | Y | Y | Y |

| 22-36 | Y | Y | Y | Y | Y |

| 20-40 | Y | Y | Y | Y | Y |

| 28-40 | Y | Y | Y | Y | Y |

| 30-40 | Y | Y | Y | Y | Y |

| 40-50 | Y | Y | Y | Y | Y |

| 40-60 | Y | Y | Y | Y | Y |

| 50-60 | Y | Y | Y | Y | Y |

| Chinese Standard | International Standard | Japanese Standard / Mesh (#) | Russian GOST9206-80 | Median D50(μm) |

| w0.2 | 0-0.2 | 80000 | 0.1 | |

| w0.25 | 0-0.25 | 60000 | 0.11~0.20 | |

| w0.5 | 0-0.5 | 30000 | 0.5/0 | 0.20~0.30 |

| w1 | 0-1 | 15000 | 1/0 | 0.6~0.8 |

| w1.5- | 0-2 | 13000 | 0.8~1.0 | |

| w1.5 | 1-2 | 12000 | 2/1 | 1.1~1.3 |

| w2.5 | 1-3 | 10000 | 1.6~1.8 | |

| W3 | 2-3 | 7000 | 3/2 | 1.9~2.1 |

| w3.5 | 2-4 | 6000 | 2.6~3.0 | |

| W5- | 2-5 | 5000 | 5/3 | 3.1~3.4 |

| w5 | 3-6 | 4000 | 3.5~4.2 | |

| W5+ | 4-6 | 3500 | 4.4~5.0 | |

| w7 | 4-8 | 3000 | 7/5 | 5.0~6.0 |

| W7+ | 4-9 | 2500 | 6.1~6.5 | |

| w10- | 5-10 | 2000 | 10/7 | 6.5~7.3 |

| w10 | 6-12 | 1800 | 7.3~8.3 | |

| w10+ | 8-12 | 1600 | 8.3~9.0 | |

| w14- | 7-14 | 1500 | 9.1~10.5 | |

| w14 | 8-16 | 1300 | 14/10 | 10.0~12.0 |

| w20- | 10-20 | 1200 | 12.5~15.0 | |

| w20 | 12-22 | 1000 | 20/14 | 15.0~17.0 |

| w20+ | 15-25 | 800 | 18.0~20.0 | |

| w28 | 20-30 | 700 | 28/20 | 20~23 |

| w28+ | 22-36 | 600 | 23~26 | |

| w40- | 20-40 | 500 | 26~29 | |

| w40 | 30-40 | 450 | 40/28 | 29~32 |

| w40+ | 35-45 | 400 | 32~36 | |

| w50 | 40-60 | 350 | 60/40 | 37~43 |