The JCB Thermally Stable (TSP) is a diamond polymer formed by sintering diamond and bonding agents under high temperature and high pressure. Due to the close thermal expansion coefficient between the bonding agent and diamond, its heat resistance can reach around 1200°C. JCB TSP polycrystalline diamond features high wear resistance, excellent thermal stability, and a dense, uniform structure. It is widely used in the manufacturing of oil and geological drill bits, diamond processing, and mechanical processing tools. JCB Thermally Stable (TSP) can be processed into various shapes and specifications (such as cylindrical, conical, square, triangular, and custom polycrystalline forms) to meet the diverse needs of customers.

Our company selects different formulations and processes to produce drill bit polycrystalline under high temperature and high pressure. These products exhibit a high wear ratio and are significantly more cost-effective compared to natural diamonds, making them ideal materials for manufacturing oil and geological drill bits. They have been widely adopted by major oilfields and drill bit manufacturers both domestically and internationally. The products can be processed into various specifications and shapes (such as cylindrical, conical, square, triangular, and custom polycrystalline forms) to meet the diverse needs of customers.

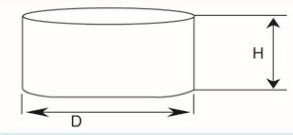

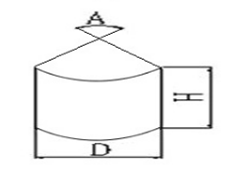

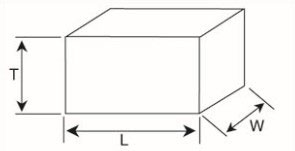

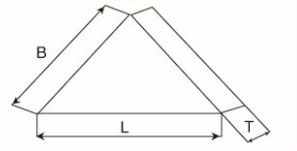

| Serial number | shape | specification | Size (mm) |

| 1 | cylindrical D: Diameter H: Altitude D: Diameter H: Altitude | Minimum size:R1012 Maximum size:R18832 | 1.0×1.2 18.8×3.2 |

| 2 | conical D: Diameter H: Altitude D: Diameter H: Altitude | Minimum size:R1012120° Maximum size:R18832120° | 1.0×1.2 18.8×3.2 |

| 3 | square L: Length W: Witch T: thickness L: Length W: Witch T: thickness | Minimum size:L151515 Maximum size:L100100200 | 1.5×1.5×1.5 10×10×20 |

| 4 | triangle L,B: Length of side T: thickness L,B: Length of side T: thickness | Minimum size:T30303026 Maximum size:T70707050 | 3.0×3.0×3.0×2.6 7×7×7×5 |

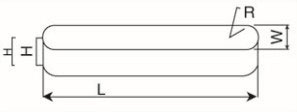

| 5 |  L: Length H:Altitude W: Witch R: circularity L: Length H:Altitude W: Witch R: circularity | Minimum size:A100303015 Maximum size:A1001005025 | 10×3×3×R1.5 10×10×5×R2.5 |

| 6 | spherical | ||

| 7 | Other abnormity | ||

| 8 | Ni plating/Ti |