Features:

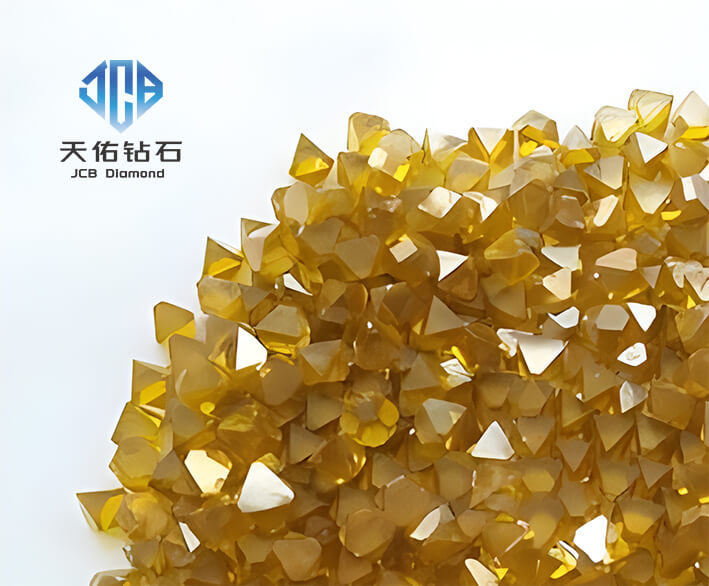

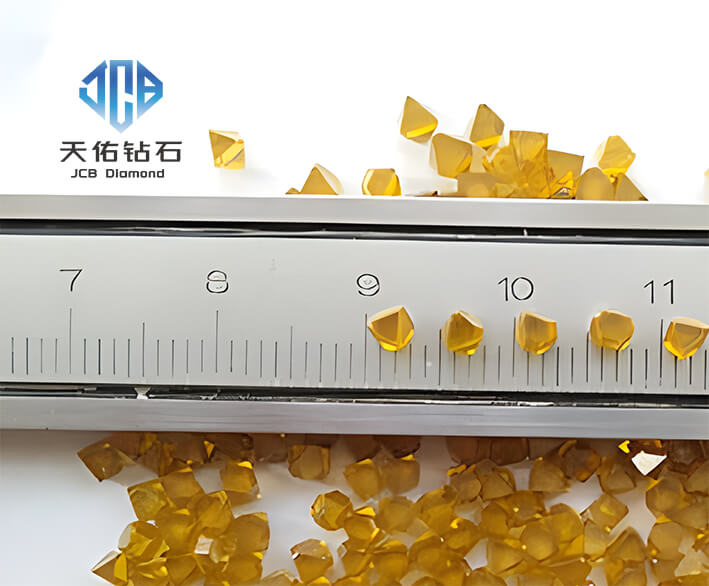

High hardness: Single crystal diamond is the hardest substance known in nature. Large-grained single crystal diamond also has extremely high hardness,

which makes it have unique advantages in fields such as processing and cutting that require extremely high material hardness.

For example, in ultra-precision processing, large-grained single crystal diamond tools can be used to process high-hardness materials, such as cemented carbide, ceramics, etc., and can achieve high-precision and high-efficiency processing.

Good optical properties: Diamond has excellent optical properties, including high transparency, high refractive index and low dispersion.

Large-grained single crystal diamond has broad application prospects in the field of optics, such as optical windows, lenses and other optical components.

High chemical stability: The chemical properties of diamond are very stable and it is not easy to react chemically with other substances.

This characteristic enables large-grained single crystal diamond to maintain stable performance even in harsh chemical environments,

and can be used in some occasions that require high chemical stability of material

Good thermal properties: Diamond has high thermal conductivity and thermal stability. Large-grained single crystal diamond can effectively conduct heat and maintain stable performance in high temperature environments.

This makes it potentially useful in thermal management in the electronics, semiconductor and other fields, such as heat dissipation components for manufacturing high-power electronic devices.

Preparation method:

High temperature and high pressure method: This is a traditional diamond preparation method that simulates the high temperature and high pressure environment inside the earth to convert carbon sources such as graphite into diamond.

When preparing large-grained single-crystalline diamond,

it is necessary to precisely control parameters such as temperature, pressure, and carbon source to ensure the growth quality and size of diamond.

Chemical vapor deposition (CVD): This is a diamond preparation method that has developed rapidly in recent years. Under certain temperature and pressure conditions, carbon-containing gases react chemically on the substrate to deposit diamond.

The CVD method can produce high-quality large-grained single-crystalline diamonds and can precisely control the growth process of diamonds. It is currently one of the main methods for preparing large-grained single-crystalline diamonds.

Application field:

Mechanical processing field: Large-grained single-crystalline diamonds can be made into tools such as cutting tools and grinding tools for processing high-hardness and high-precision parts.

For example, in the aerospace field, large-grained single-crystal diamond tools can be used to process key components such as engine blades and turbine disks, which can improve processing efficiency and quality.

Electronic semiconductor field: Because large-grained single-crystal diamond has good thermal and electrical properties, it can be used to manufacture heat dissipation components of high-power electronic devices, substrates of semiconductor devices, etc.

Optical field: As mentioned above, it can be used to manufacture optical components such as optical windows, lenses, laser crystals, etc., and has important applications in laser technology, optical communications and other fields.

Jewelry field: Large-grained single-crystal diamonds can be made into diamond jewelry after cutting, polishing and other processes, which have high value and beauty.