I. Industry Overview

(I) Background of the Development of the Artificial Diamond Industry

As an important superhard material, artificial diamond has been studied since it was confirmed to be composed of pure carbon in the 18th century. In 1963, China's first artificial diamond was successfully developed in Beijing. This major breakthrough laid a solid foundation for the development of my country's artificial diamond industry. After more than 60 years of continuous development, my country's artificial diamond industry has achieved remarkable achievements and has basically formed a complete industrial system.

In 2000, my country became the world's largest producer of artificial diamonds. Since then, my country's diamond production has continued to rise. By 2023, my country's diamond production will increase to 16.597 billion carats, accounting for more than 90% of the world's total production. At the same time, the industry market size is about 4.702 billion yuan. The rapid development of the artificial diamond industry is due to the continuous advancement of technology and the continuous growth of market demand.

(II) Analysis of the artificial diamond industry chain

1. Upstream: The upstream of the artificial diamond industry chain mainly includes raw and auxiliary materials such as graphite powder and metal catalysts, as well as production tools. In 2021, China's graphite powder production reached 3.5 million tons, of which about 20% was used for artificial diamond production; in terms of metal catalysts, the domestic self-sufficiency rate reached more than 90%. In the past five years, the price of graphite powder has fluctuated slightly, with an average annual increase of no more than 5%; the price of metal catalysts is greatly affected by the international market, but remains stable overall.

2. Midstream: Involving the synthesis of artificial diamond single crystals and micropowders, and the production of PDC polycrystalline composite sheets and polycrystalline.

3. Downstream: Artificial diamonds are widely used due to their high-quality performance, covering many fields such as jewelry, stone processing, aerospace, power electronics, mechanical processing, and medicine. With the product upgrades and application field expansion of downstream diamond product companies, customers have put forward higher requirements for the quality and extreme performance of artificial diamonds, further promoting the high-quality development of artificial diamonds.

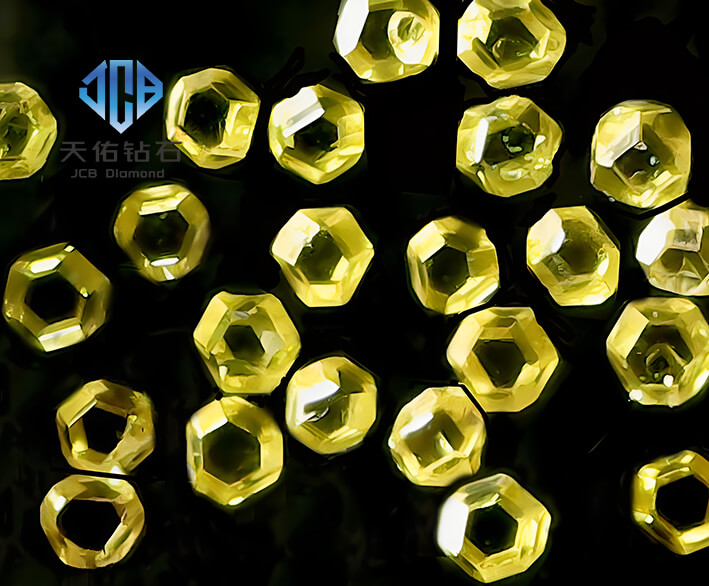

2. Characteristics of artificial diamond fines

(I) Physical performance characteristics

As a sub-category of artificial diamonds, artificial diamond fines also have excellent physical properties. First of all, it has high hardness and is known as the "king of hardness". It is 10 times harder than steel, which enables artificial diamond fines to play an excellent role in cutting and grinding in many fields. Secondly, the melting point of artificial diamond fines is high, which can reach 3550℃ and the boiling point is as high as 4827℃. This high melting point and boiling point enable it to maintain stable performance in high temperature environments, and is suitable for some industrial production links that require extremely high heat resistance of materials. In addition, artificial diamond fines also have good thermal conductivity, electrical insulation, light transmittance and corrosion resistance. Good thermal conductivity enables it to transfer heat quickly, and it has important applications in heat dissipation of electronic devices; electrical insulation ensures its safe use in the electronics industry; light transmittance makes it possible to be used in the optical field; and corrosion resistance enables it to maintain stable performance in various harsh environments.

(II) Application field characteristics

Artificial diamond fines are widely used in many fields and play a unique role in different fields.

In industrial production, artificial diamond fines are ideal cutting materials. Due to its high hardness, it can be used to manufacture various processing tools, such as saw blades, saw blades, rope saws, wire saws, and cutting tools in the fields of stone, non-ferrous metals, and difficult-to-process composite materials (such as carbon fiber composite materials). At the same time, artificial diamond fines can also be used to make grinding tools. The product types are mainly divided into three categories: bonded abrasives, coated abrasives, and paste-like liquid abrasives, including grinding wheels, grinding heads, cutting discs, grinding discs, oilstones, emery cloths, abrasive belts, polishing films, abrasive pastes, and abrasive fluids. In addition, drilling tools mainly include geological drill bits, oil (gas) well drill bits, and engineering thin-walled drill bits, which are respectively used in geological exploration, oil (gas) exploration and mining, and drilling holes in various buildings.

In terms of semiconductor devices, artificial diamond fines are used in heat sinks for semiconductor devices due to their high thermal conductivity and electrical insulation, which helps to improve the performance and service life of semiconductor devices. As an excellent material, artificial diamond fines have extremely high hardness, thermal stability, optical transparency, and electrical properties, as well as excellent thermal conductivity and mechanical strength, providing a wide range of possibilities for its application in the semiconductor industry. At present, the mainstream methods of synthetic diamonds can be divided into high temperature and high pressure method (HPHT) and chemical vapor deposition method (CVD). CVD method can produce high-quality diamonds. Due to its superior chamber vacuum environment, the prepared diamond materials have fewer internal impurities and are highly favored. The main goal of MPCVD synthetic semiconductor diamond materials is to achieve wafer-level (2 inches and above) and low-defect diamond single crystals.

In the electronics industry, the diamond film of artificial diamond fines is used to manufacture optical acoustic devices, pressure processing and cutting tools due to its good light transmittance and corrosion resistance.

In jewelry processing, artificial diamond fines are also precious jewelry materials. Cultured diamonds are gem-grade artificial diamonds that can be used in the field of jewelry. In recent years, China's cultured diamond industry has emerged, and the market acceptance of cultured diamonds has gradually increased. China's rough cultured diamond sales in 2021 were 1.4 million carats, and it is expected that China's rough cultured diamond sales will reach 4 million carats in 2025, with a compound growth rate of about 30%.

In medical devices, artificial diamond fines have excellent biological inertness and corrosion resistance. They are used in surgical tools such as artificial joints and dental instruments.

In the field of optics, artificial diamond fines have high refractive index and dispersion, and can be used to make optical lenses and laser devices. Diamond has high transmittance in the entire band from X-rays to microwaves, and is an excellent optical material. For example, MPCVD single crystal diamond can be made into the energy transmission window of high-power laser devices, and can also be made into diamond windows of cosmic detectors. Diamond has the characteristics of resistance to thermal shock, chemical corrosion and mechanical wear, and has corresponding research and application in infrared windows, microwave windows, high-power laser windows, thermal imaging system windows, X-ray windows, etc.

In terms of heat sink materials, in high-power density electronic devices, artificial diamond fines can be used as packaging materials to improve the performance of devices.

In environmental protection technology, boron-doped diamond (BDD) has a wide potential window and high oxygen evolution potential, which can be used for electrochemical treatment of organic wastewater. It is an efficient, energy-saving, green and non-secondary pollution technology.

In terms of coating materials, diamond film can be used as a wear-resistant coating and applied to the surface of plastics, glass and other materials to improve their wear resistance and service life.

In terms of scientific research materials, in scientific research, artificial diamond fines are used in various experiments and technology development due to their excellent physical properties.

In national defense and cutting-edge science and technology, artificial diamond fines play an important role due to their high temperature resistance, corrosion resistance, and radiation resistance.

III. Preparation method of artificial diamond fines

(I) In-situ growth surface roughening fine particle artificial diamond manufacturing method

1. First, obtain the diamond nucleus, mix it into the graphite powder, and add additives and high melting point strong carbides. The additives include at least two of Cr, Mn, Ce and S, and the high melting point strong carbides include at least one of W, Ca and Si. The ratio of the mass of the diamond nucleus, additives and high melting point strong carbides to the mass of the graphite powder is 1:10000 - 2:10000.

2. Feed the mixed ingredients into the mold and press them into diamond core rods. The specific process is as follows: mix part of the diamond nucleus and part of the additives into part of the graphite powder to obtain a first mixture; mix the remaining diamond nucleus, the remaining additives, and the remaining high melting point strong carbides to obtain a second mixture. Use a feeding device to feed the first mixture and the second mixture into the mold. The feeding device includes a first storage tank, a second storage tank, a discharge pipe and a connecting pipe. The discharge pipe includes an inner tube and an outer tube, the inner tube is inserted into the outer tube from top to bottom, the upper end of the inner tube is connected to the first storage tank, and the inner tube is provided with a first valve. The upper end of the outer tube is closed, one end of the connecting pipe is connected to the side of the outer tube, and the other end is connected to the second storage tank, and the connecting pipe is provided with a second valve. The first mixture is loaded into the first storage tank, and the second mixture is loaded into the second storage tank. When feeding the material into the mold, first open the second valve and close the first valve, so that the second mixture enters the mold through the space between the inner tube and the outer tube and is spread on the bottom surface of the mold. Then, the first valve and the second valve are opened at the same time, so that the first mixture and the second mixture enter the mold at the same time. Finally, the first valve is closed, so that the second mixture enters the mold through the space between the inner tube and the outer tube. After the addition is completed, the second valve is closed, and after pressing, a diamond core rod material in which the second mixture covers the first mixture is obtained.

3. The diamond core rod material is placed in a pyrophyllite mold for deoxidation at 900-1000℃.

4. The deoxidized diamond core rod is placed in a pyrophyllite mold, grown at 4.5-5.5GPa, 1100-1400℃ for 16-20 minutes, and then roughened at 3.5-4.5GPa, 1400-1600℃ for 1-3 minutes to obtain a finished diamond. This method can achieve the roughening treatment of diamond while ensuring the strength of diamond.

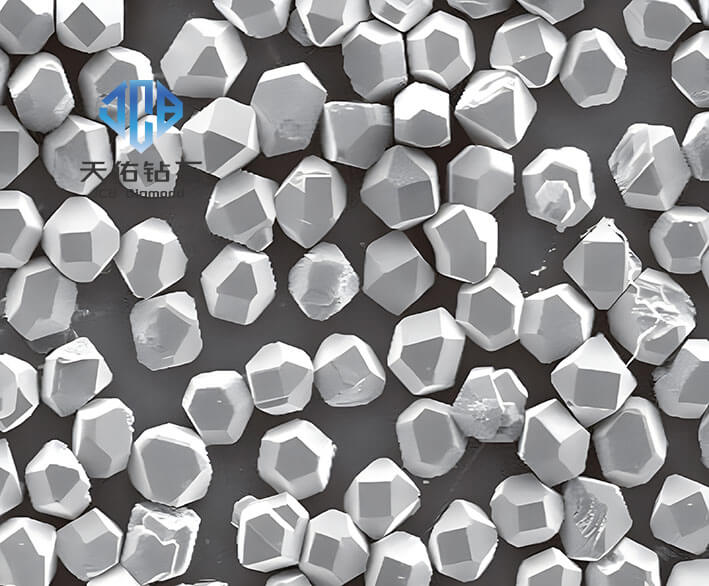

(II) General preparation method of artificial diamond

1. The graphite powder and the catalyst powder are stirred evenly to form a mixture, and then molded into a synthetic column by molding. The graphite powder is nitrogen-modified graphite powder, and urea is used as a nitrogen source. The graphite powder is coated and then sealed to obtain nitrogen-modified graphite powder. The catalyst powder is iron-cobalt-nickel alloy powder, and the mass ratio of iron powder, cobalt powder and nickel powder in the iron-cobalt-nickel alloy powder is 67:1:17-20. The catalyst powder adopts micron-grade fine powder with a particle size of no more than 50 microns. The mass ratio of graphite powder to catalyst powder is 1:0.5-1, and the stirring speed is 100-300r/min. The mixing is carried out by ball milling, which can homogenize the particle size and effectively realize the stable mixing of catalyst powder and graphite powder.

2. Perform high temperature and high pressure synthesis to obtain artificial diamond. High temperature and high pressure synthesis adopts two gradient heating and pressurization. The temperature of the first gradient is 1300-1700℃; the pressure is 4-5GPa, and the time is 5-10min; the temperature of the second gradient is 1700-1800℃, the pressure is 5.5-6GPa, and the time is 15-20min. High temperature and high pressure synthesis is to synthesize and transform the synthesis column and auxiliary parts on a six-sided top press.

3. The artificial diamond is treated with acid, using a mixed acid solution of HNO3 and H2SO4 with a molar ratio of 3:1. After acid treatment, the insoluble matter is washed with clean water to neutrality, and the green artificial diamond is obtained by drying at a drying temperature of 110-120℃. This method uses nitrogen-doped graphite powder as raw material for the first time, realizing the non-destructive and pollution-free addition of nitrogen elements, while alleviating the infiltration of metal impurities.