I. Industry Overview

(I) Definition and Classification of Diamond Crusher

Diamond crusher is a super-hard grinding and polishing material produced by crushing, purifying, screening and other processes using high-quality single-crystal artificial diamond as raw material. It is mainly classified into different categories according to particle size,

such as particle size 0-30 microns,

particle size 30-100 microns,

and particle size >100 microns.

(II) Characteristics of Diamond Crusher

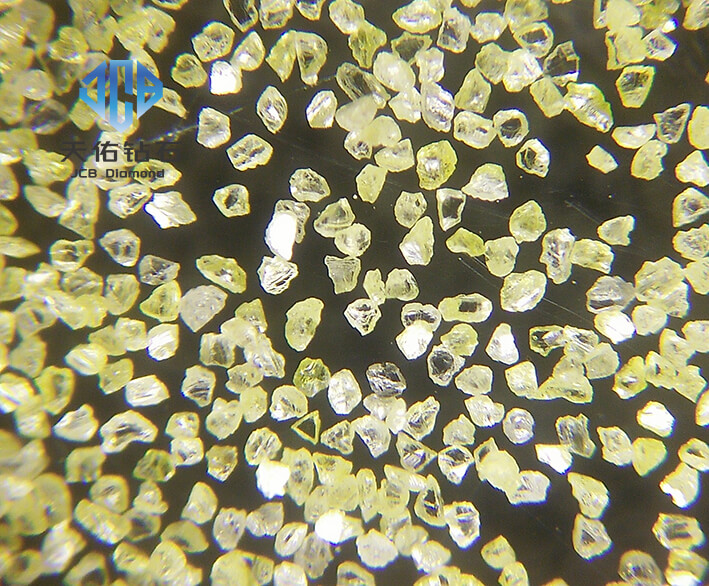

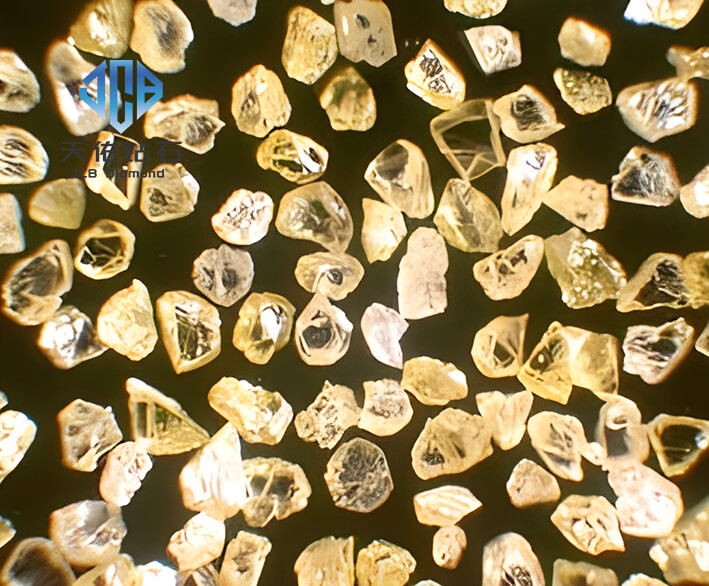

Diamond crusher has the characteristics of incomplete crystals, irregular crystal shapes, rough surfaces, sharpness and wear resistance, as well as extremely high hardness, excellent wear resistance and good corrosion resistance.

Specifically, diamond particles have extremely high hardness,

which is almost unmatched by any other material, making it an ideal choice for processing materials with higher hardness (such as concrete, glass, stone, etc.). Secondly, diamond crusher has excellent wear resistance.

When in contact with other materials, diamond particles are not easy to wear,

so their cutting and grinding effects can be maintained for a long time. In addition, even in a humid or chemically corrosive environment, diamond particles can maintain their stability and are not easily corroded or damaged.

(III) Production process of diamond crushing materials

The production process of diamond crushing materials includes the selection of high-quality single-crystal artificial diamonds as raw materials, and the processes of crushing, purification, screening, etc. In the production process,

the quality of the raw materials must be ensured first, and high-quality single-crystal artificial diamonds must be selected. The crushing process requires the use of appropriate equipment and technology to ensure that the diamond particles are crushed evenly,

while avoiding excessive crushing that causes the particles to be too small.

The purification process is mainly to remove impurities and improve the purity of the diamond crushing materials. The screening process is to classify the diamond particles according to different particle size requirements. In the production process,

it is necessary to pay attention to controlling the parameters of each link to ensure the quality and performance of the product. At the same time, it is necessary to strictly abide by the safety production regulations to ensure the safety of the production process.

II. Application Analysis

(I) Application in Different Fields

Diamond crushing materials are widely used in different fields:

Resin bond abrasive tools: When diamond crushing materials are used as resin bond abrasive tools, they are mainly used to grind the outer circle of carbide cutting tools, measuring tools, cone drill ball teeth, etc.,

the surface of molds, and slotting.

For example, resin grinding wheels, with their sharp and wear-resistant characteristics, can efficiently process materials such as carbide.

Electroplated bond abrasive tools: Mainly used for electroplated diamond assorted files and trepanning knives. Among them, assorted files are mainly used for grinding molds made of carbide or difficult-to-grind steel;

trepanning knives are used for trepanning of optical glass and semiconductor silicon wafers.

With its high hardness and good wear resistance, it can maintain stable performance during the processing process.

Vitrified bond abrasive tools: They can well meet the needs of high-precision grinding and high-efficiency grinding of difficult-to-process materials and general materials, and are suitable for use in CNC grinders and automated production lines, such as flat,

cup-shaped, and bowl-shaped grinding wheels.

The application of diamond crusher in vitrified bond abrasive tools fully utilizes its incomplete crystal and rough surface characteristics, increases the bonding force with the binder, and improves the grinding efficiency and precision of the abrasive tools.