1. Source and preparation of diamond shaping materials

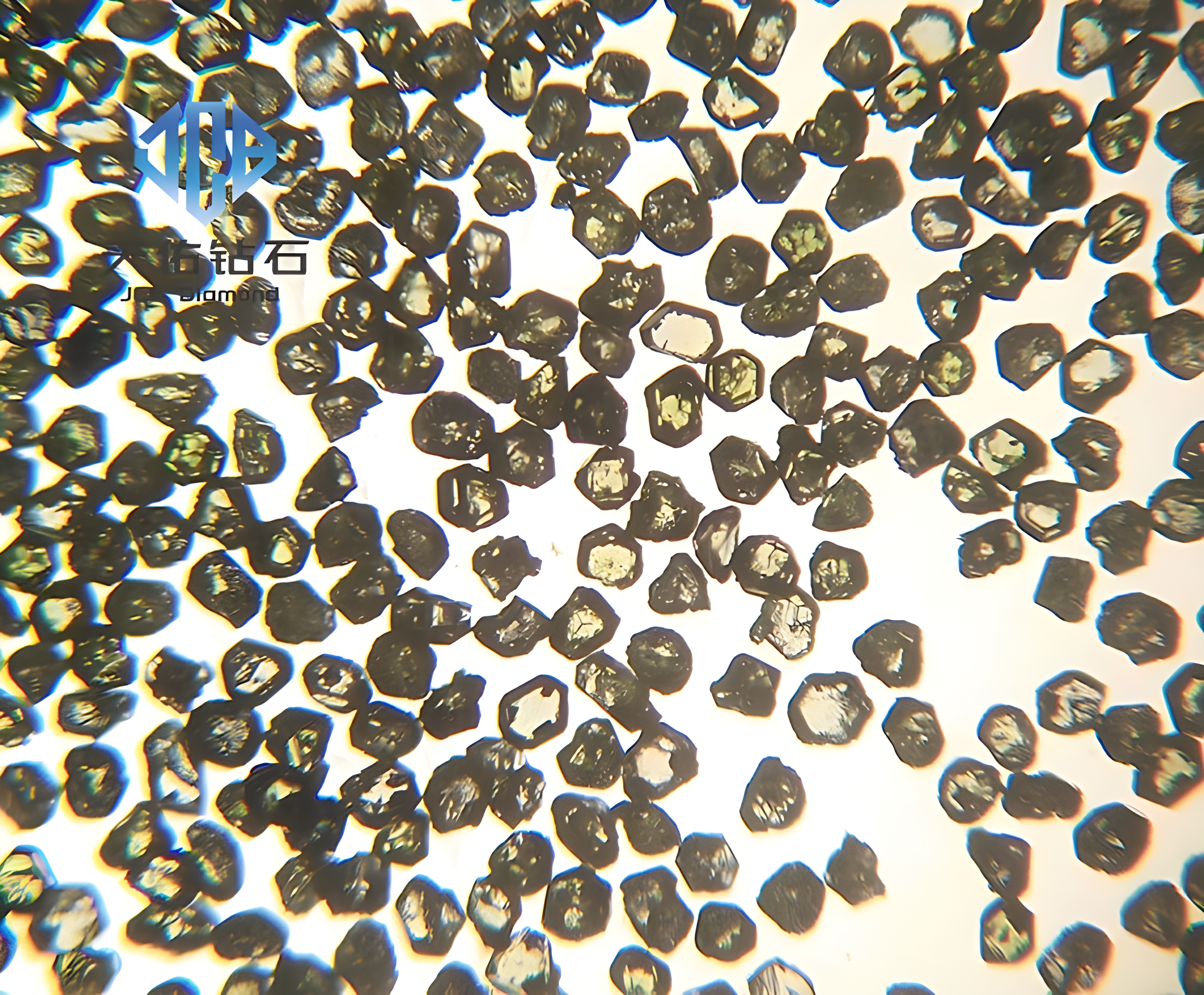

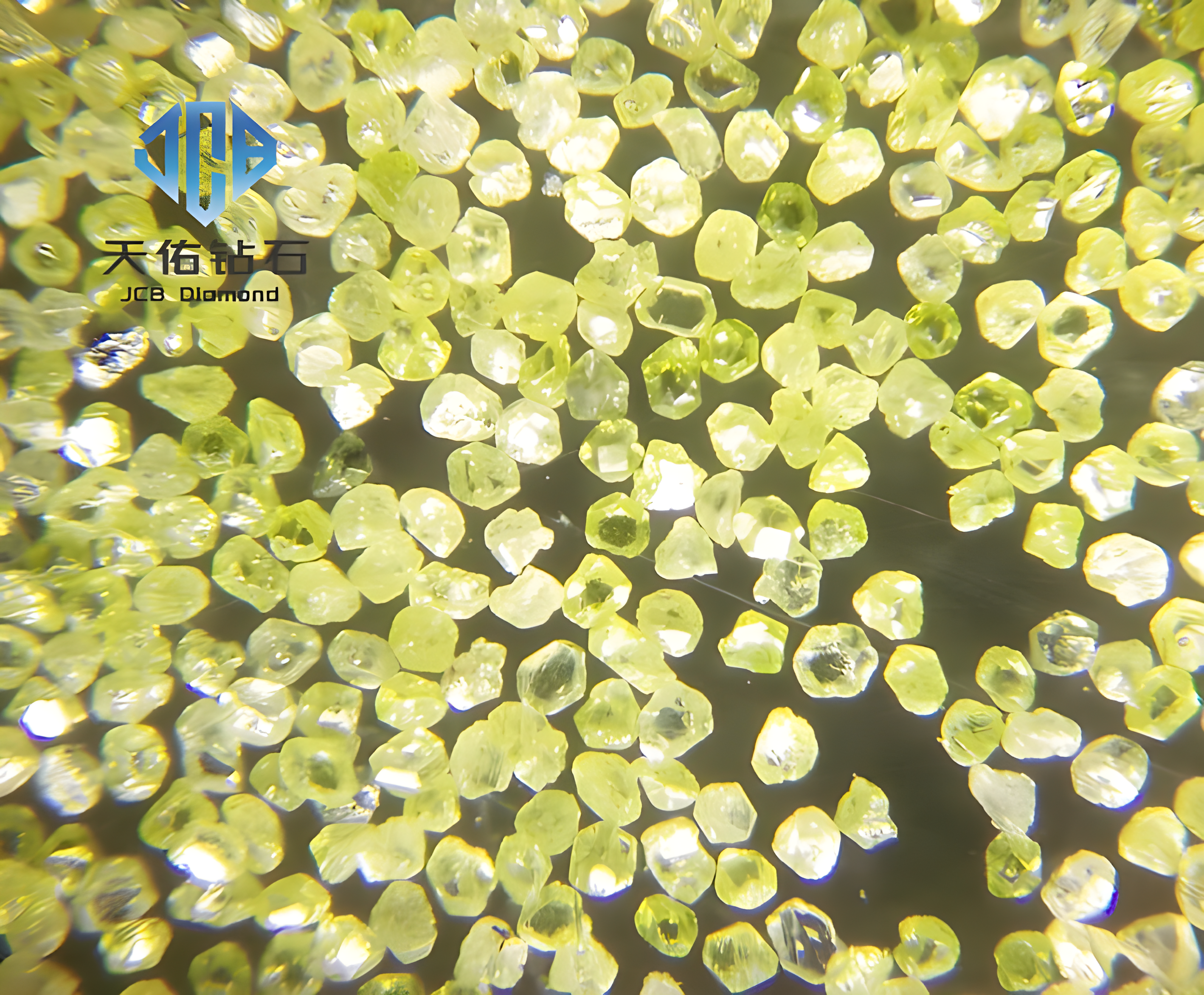

The raw materials of diamond shaping materials are usually natural diamonds or synthetic diamonds. For natural diamonds, after mining, they will go through screening, classification and other steps to select suitable particles for subsequent shaping.

Synthetic diamonds are produced by high-temperature and high-pressure synthesis or chemical vapor deposition, and then shaped according to demand.

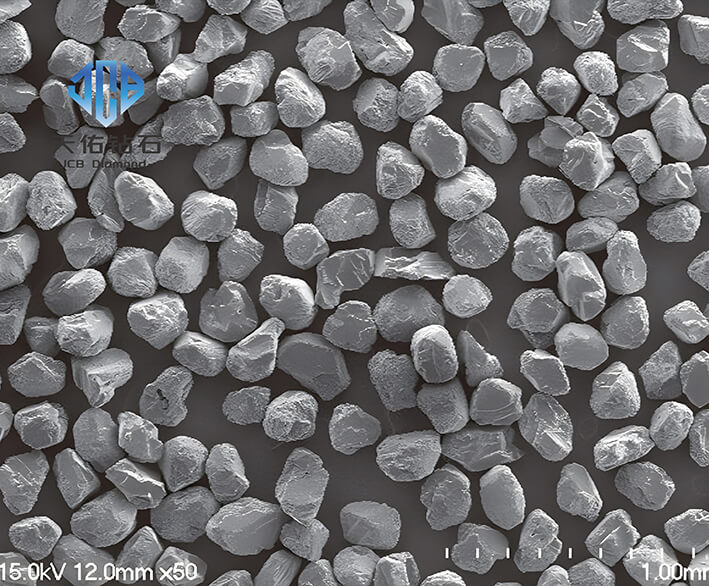

In terms of shaping technology, the common mechanical grinding method is to use high-precision grinding equipment, with specific abrasives, and grind the diamond particles according to the set parameters to achieve the desired shape, such as spherical, cubic, etc.

There is also a laser cutting method, which uses a high-energy laser beam to accurately cut the diamond to shape a more complex and precise shape to meet some application scenarios with high requirements for shape accuracy.

2. Performance characteristics of diamond shaping materials

High hardness: Diamond itself has the highest hardness in nature, and this characteristic is still retained after shaping, which makes it easy to cut and grind many materials with relatively low hardness during various processing processes, such as stone, metal materials, etc., and can show excellent cutting ability.

Good wear resistance: Due to its special crystal structure and extremely high hardness, diamond shaping materials have very little wear during long-term use. In some industrial scenarios that require long-term repeated use, it can greatly reduce the replacement frequency and improve production efficiency.

For example, the application in abrasive tools can maintain good grinding performance for a long time.

Chemical stability: It hardly reacts with general acids, alkalis and other chemicals at room temperature, which makes it still able to play a stable role in some processing or application scenarios with more complex chemical environments. For example, when it is used in grinding and stirring equipment in some chemical fields,

its performance will not be degraded due to the erosion of chemicals.

3. Application fields of diamond shaping materials

Abrasive tool manufacturing field: Diamond shaping materials are important raw materials for manufacturing various grinding wheels, abrasive belts and other abrasive tools. When grinding metal parts, ceramic products, etc., it can achieve high-precision and high-efficiency grinding, so that the processed surface can reach high finish and precision requirements. It plays an indispensable role in the grinding of automobile engine parts and the grinding of precision molds.

Drilling industry: In the fields of petroleum and geological drilling, drilling tools such as drill bits made of diamond shaping materials can quickly and effectively penetrate hard formations such as rocks with their high hardness and wear resistance, improve drilling efficiency, and maintain good working conditions during long-term drilling operations, reducing the cost and time consumption caused by frequent replacement of drill bits.

Jewelry processing industry: For some processes that require fine grinding and shaping of gemstones, tools made of diamond shaping materials are the best choice. It can grind gemstones into various exquisite shapes to meet the high requirements of jewelry production for shape and gloss.

Electronic industry: In the manufacturing of electronic chips and other links, high-precision grinding, cutting and other processing operations are required for materials such as silicon wafers. Cutting tools and grinding discs made of diamond shaping materials can well meet these requirements and ensure the accuracy and quality of electronic components production.

4. Development trend of diamond shaping materials

Improvement of fine processing technology: In the future, more advanced shaping processing technologies will be continuously developed to shape more precise and complex shapes, and further expand its application in high-precision fields such as micro-nano processing, such as playing a greater role in the manufacture of precision electronic devices such as micro sensors.

Combined application with new materials: With the continuous emergence of new materials, diamond shaping materials are expected to be combined with some new materials with special properties to develop composite products with multiple excellent properties, such as combining with materials with self-lubricating properties to manufacture tools used in high-speed, heavy-load and low-friction mechanical processing scenarios.

Environmental protection and sustainable development: Pay more attention to environmental protection requirements in the production and application links, develop green shaping processing technology, reduce energy consumption and waste emissions, and improve the recycling efficiency of diamond shaping materials, so that their entire life cycle is more in line with the concept of sustainable development.