I. Introduction

General-purpose diamond powder is an important superhard material with extensive and critical applications in many industrial fields. As modern manufacturing and electronics industries continue to develop towards high precision and high performance,

research on the performance and quality of general-purpose diamond powder is becoming increasingly important. This report aims to deeply analyze its related characteristics, production process, application status and future development trends.

II. Overview of diamond powder

(I) Definition and classification

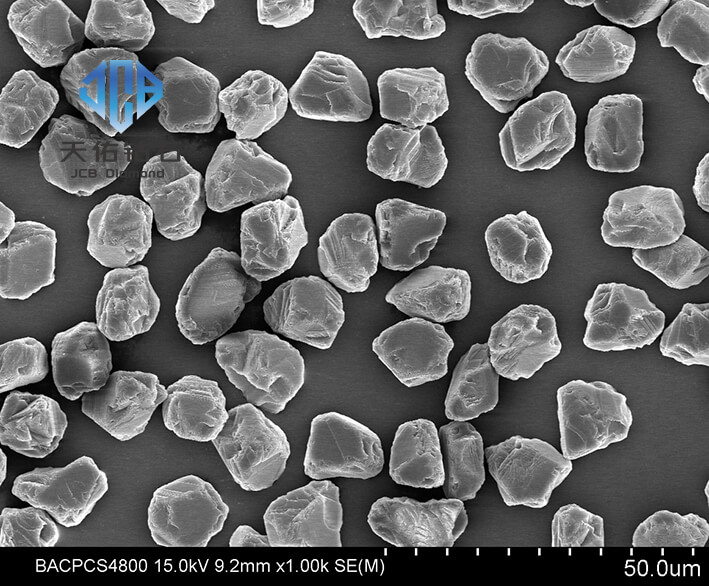

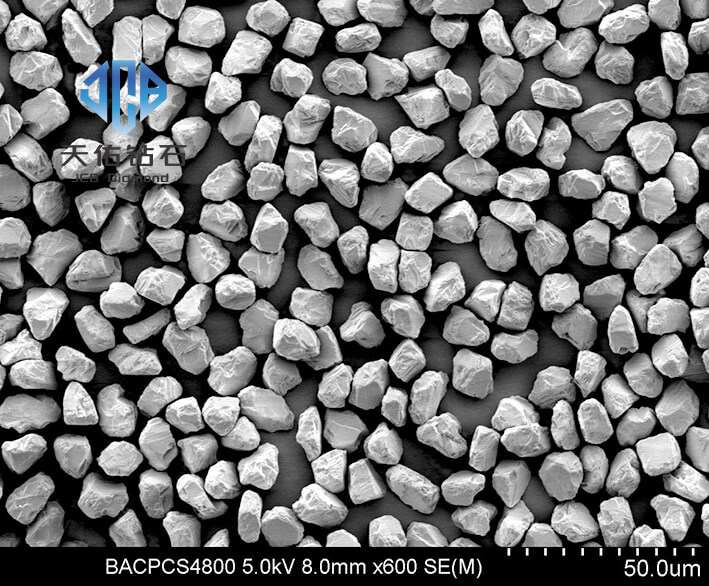

General-purpose diamond powder refers to diamond particles with a particle size as fine as micrometers. It can be divided into multiple different specifications according to its particle size, such as 0-0.5μm, 0.5-1μm, 1-3μm and other different ranges. In terms of crystal structure and quality,

it can be divided into different grades to meet different usage requirements.

(II) Physical and chemical properties

Diamond powder has the characteristics of high hardness, high wear resistance and good chemical stability common to diamond materials. Its Mohs hardness is as high as 10, which can effectively grind various hard materials during grinding, polishing and other processing processes,

and it is not easy to react with chemical substances such as acids and alkalis at room temperature, ensuring its applicability in a variety of complex processing environments.

III. Production process

(I) Raw material selection

The raw materials for producing general-purpose diamond micropowders mainly include artificial diamond single crystals and diamond polycrystals. Artificial diamond single crystals are produced through processes such as high temperature and high pressure synthesis.

Their quality and particle size are highly controllable and are currently the most commonly used source of raw materials; diamond polycrystals are also used in the production of micropowders with some specific performance requirements, such as when better toughness is required.

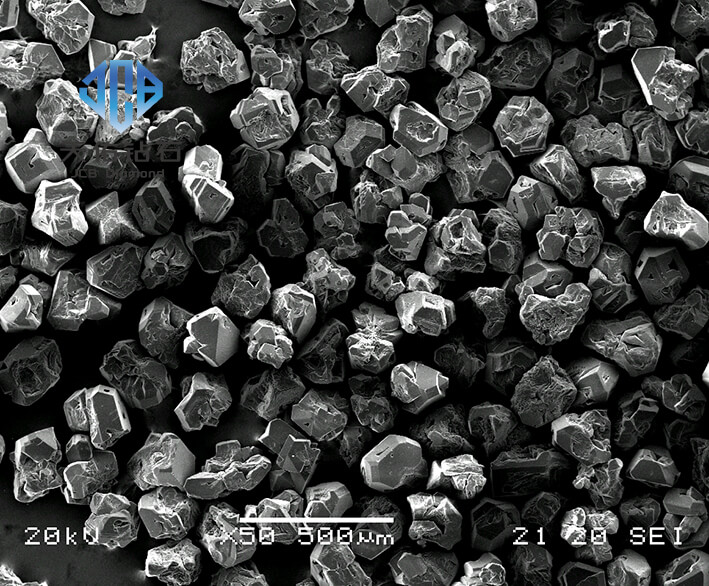

(II) Crushing and classification

The raw materials are mechanically crushed, air flow crushed, etc. to crush large diamond particles into micron-level particles. Then, the micropowders are screened according to the preset particle size specifications using precision grading technologies such as hydraulic grading and air flow grading to ensure the accuracy and consistency of the particle size of the final product.

(III) Surface treatment

In order to enhance the dispersibility of diamond powder in practical applications and its ability to bind with binders, surface treatment is often required. Common treatment methods include metal plating (such as nickel, copper, etc.) and chemical modification.

IV. Application fields

(I) Precision grinding and polishing

In the manufacture of precision components such as optical lenses and silicon wafers, general-purpose diamond powder is an indispensable grinding and polishing material. For example, when producing high-precision camera lens lenses, fine grinding and polishing can achieve extremely high flatness and smoothness on the lens surface,

meeting the high-quality requirements of optical imaging.

(II) Superhard tool manufacturing

Diamond powder plays an important role in the grinding and coating preparation of superhard tools. By using powder for precision grinding of tool edges, the sharpness and wear resistance of tools can be improved, the service life of tools can be extended, and the processing accuracy can be improved.

It has obvious advantages in metal cutting and other processing fields.

(III) Electronic material processing

For the processing of semiconductor materials, printed circuit boards, etc. in the electronics industry, diamond micropowder can achieve fine processing of their surfaces, remove excess materials, ensure the performance and dimensional accuracy of electronic components,

and help electronic equipment develop in the direction of miniaturization and high performance.

V. Market status and competition pattern

At present, the global general-purpose diamond micropowder market size shows a steady growth trend. Among them, China is one of the main producers. With a relatively complete industrial chain, advanced production technology and cost advantages, it occupies a large share in the international market.

However, competition in the industry is also fierce. Many companies continue to make efforts in product quality, technology research and development, brand building, etc. to compete for more market share.

VI. Development trend

(I) High performance

In the future, general-purpose diamond micropowder will develop in the direction of higher hardness, more uniform particle size, better dispersibility and other high-performance directions to meet the stringent needs of the growing high-end manufacturing industry.

(II) Green environmental protection

In terms of production technology, more attention will be paid to green environmental protection, reducing the emission of pollutants generated in the links of crushing, grading and surface treatment, and developing more environmentally friendly process technologies and materials.

(III) Intelligent production

With the help of intelligent equipment and control systems, the production process of diamond micropowder can be automated and precisely controlled to improve production efficiency and product quality stability.

VII. Conclusion

General-purpose diamond micropowder plays an extremely important role in modern industry. The continuous improvement of its performance, continuous optimization of production processes and further expansion of its application areas are of great significance. With the development of various related industries,

its future development prospects are broad, but it also faces many challenges in technology, market and other aspects. It requires the joint efforts of enterprises and scientific research institutions in the industry to promote it to better serve the high-quality development of manufacturing and other fields.