1. Introduction

As an important superhard material, polycrystalline diamond powder plays a key role in many industrial fields. Its unique properties make it an ideal material for grinding, polishing, cutting and other processing processes. With the continuous advancement of industrial technology and the continuous expansion of emerging application fields,

the market demand for polycrystalline diamond powder continues to grow, and research on its performance and application has also received increasing attention.

2. Definition and characteristics of polycrystalline diamond powder

Definition

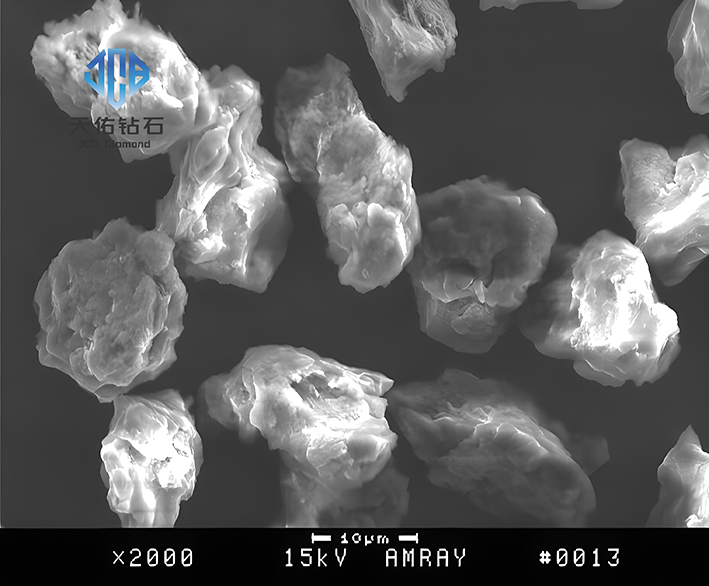

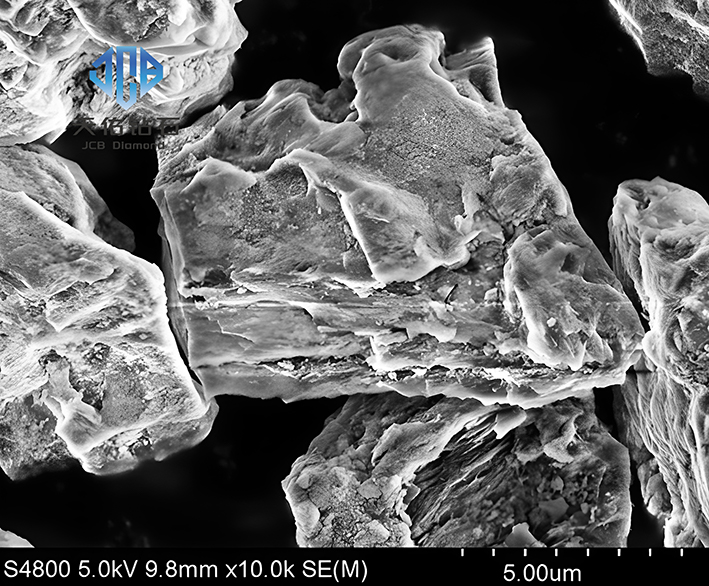

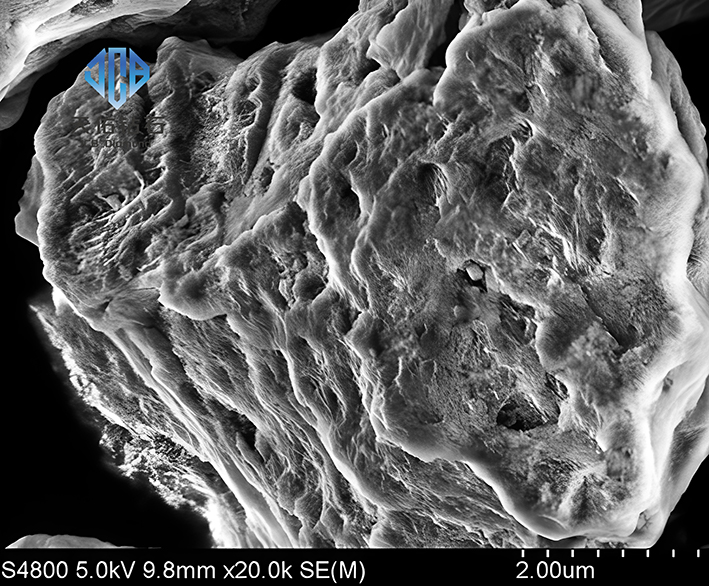

Polycrystalline diamond powder is a micron and submicron polycrystalline particle formed by diamond grains with a diameter of 5-10nm combined by unsaturated bonds.

Characteristics

High hardness: Diamond is the hardest substance in nature. Polycrystalline diamond powder inherits this property and has extremely high hardness, which can effectively process various hard materials.

High toughness: Compared with single crystal diamond powder, polycrystalline diamond powder has isotropic internal cleavage planes, has higher toughness, is not easy to break during processing, and can improve processing efficiency and quality.

Good thermal stability: In high temperature environment, polycrystalline diamond powder can still maintain good performance and is suitable for some high temperature processing scenarios.

Chemical stability: It has good chemical stability, is not easy to react with other chemicals, and can be used in various chemical environments.

III. Production process

The production process of polycrystalline diamond powder mainly includes the following steps:

Raw material preparation: Select high-quality diamond single crystals as raw materials, and its quality directly affects the performance of polycrystalline diamond powder.

Crushing: Diamond single crystals are crushed into tiny particles by mechanical crushing, air flow crushing and other methods.

Shaping: The crushed particles are shaped to make their shape more regular and improve the quality and performance of the product.

Particle size sorting: Polycrystalline diamond powders of different particle sizes are sorted by screening, centrifugation and other methods to meet the needs of different application scenarios.

Surface treatment: Surface treatment of polycrystalline diamond powder is performed as needed, such as metal plating, oxide, etc., to improve its dispersibility, wettability and other properties.

4. Application fields

Grinding and polishing

In the field of mechanical processing, polycrystalline diamond powder can be used to grind and polish various cemented carbides, ceramics, gemstones and other materials, which can improve processing efficiency and surface quality. For example, in the processing of automobile engine parts, polycrystalline diamond powder can be used to grind piston rings, valves and other parts to improve their sealing and wear resistance.

In the processing of optical glass, polycrystalline diamond powder can be used to polish the glass surface to improve its transparency and optical properties.

Semiconductor manufacturing

Polycrystalline diamond powder can be used for cutting and grinding semiconductor chips, which can improve the processing accuracy and efficiency of chips. For example, in the cutting process of silicon wafers, polycrystalline diamond powder can be used as the cutting edge material of the cutting tool to improve the cutting speed and quality.

In the grinding of semiconductor packaging materials, polycrystalline diamond powder can be used to grind the surface of the packaging material to improve its flatness and finish, thereby improving the quality and reliability of semiconductor packaging.

Petroleum and geological exploration

In the process of oil drilling, polycrystalline diamond powder can be used to manufacture the cutting teeth of the drill bit to improve the drilling speed and service life of the drill bit.

In geological exploration, polycrystalline diamond powder can be used to grind rock samples for mineral analysis and geological research.

Other fields

In the field of coatings and inks, polycrystalline diamond powder can be used as an additive to improve the wear resistance, corrosion resistance and scratch resistance of coatings and inks.

In the field of medical devices, polycrystalline diamond powder can be used to manufacture surgical knives, dental instruments, etc., with good biocompatibility and wear resistance.

V. Market analysis

Market size and growth trend

The global polycrystalline diamond powder market size shows a trend of increasing year by year. With the continuous advancement of industrial technology and the continuous expansion of emerging application fields, the market demand for polycrystalline diamond powder continues to grow. It is expected that the global polycrystalline diamond powder market size will continue to maintain a relatively fast growth rate in the next few years.

China is the world's largest producer and consumer market of polycrystalline diamond powder, and the domestic polycrystalline diamond powder market size accounts for a large proportion of the global market size. In recent years, with the rapid growth of the domestic economy and the transformation and upgrading of the manufacturing industry, the demand for polycrystalline diamond powder has increased significantly.

Competition pattern

The global polycrystalline diamond powder market is highly competitive, with major manufacturers concentrated in Europe, America, Japan and China. Among them, European, American and Japanese companies have strong advantages in technology research and development and product quality, occupying a large share of the high-end market; Chinese companies have advantages in production scale and cost control, occupying a large share of the mid- and low-end market.

With the continuous improvement of the technical level and product quality of Chinese companies, the competitiveness of Chinese companies in the global polycrystalline diamond powder market has gradually increased, and they are expected to occupy a larger share of the high-end market in the future.

VI. Development Prospects and Challenges

Development Prospects

Technological innovation promotes the expansion of application areas: With the continuous innovation of technology, the performance of polycrystalline diamond powder will continue to improve, and its application areas will continue to expand. For example, in the field of new energy, polycrystalline diamond powder can be used to manufacture electrode materials for lithium-ion batteries, improving battery performance and life.

Market demand continues to grow: With the continuous development of the global manufacturing industry and the continuous rise of emerging industries, the market demand for polycrystalline diamond powder will continue to grow. Especially in the fields of semiconductors, new energy, aerospace, etc., the market demand for polycrystalline diamond powder will show a rapid growth trend.

Challenges

Technical research and development is difficult: The production technology of polycrystalline diamond powder is relatively complex, and the technical research and development is difficult. It is necessary to continuously invest a lot of money and manpower in technical research and development to improve the quality and performance of the product.

Environmental protection pressure is increasing: During the production process of polycrystalline diamond powder, certain pollutants such as wastewater, waste gas and waste residue will be generated, which will have a certain impact on the environment. With the continuous improvement of environmental protection requirements, enterprises need to increase environmental protection investment and take effective environmental protection measures to reduce pollutant emissions.

Fierce market competition: The global polycrystalline diamond powder market is highly competitive. Enterprises need to continuously improve product quality and service levels and reduce product costs to improve market competitiveness.

VII. Conclusion

As an important superhard material, polycrystalline diamond powder has broad application prospects and market potential. With the continuous advancement of technology and the continuous growth of market demand, the production technology of polycrystalline diamond powder will continue to improve and the application field will continue to expand. At the same time, enterprises also need to face challenges in technology research and development, environmental pressure and market competition, and continuously improve their competitiveness to achieve sustainable development.