Abstract: This research report focuses on TSP (Thermally Stable Polycrystalline) polycrystalline materials, and conducts in-depth discussions and analysis on its preparation process, microstructure, performance characteristics and application fields. By combining experimental research with theoretical analysis, the unique performance advantages of TSP polycrystalline and its potential application value in multiple industries are revealed, and the challenges it currently faces and future development trends are also prospected.

1. Introduction

With the continuous development of materials science and technology, the demand for high-performance materials is growing. As a new type of material, TSP polycrystalline has gradually attracted widespread attention and research due to its excellent thermal stability, high hardness, wear resistance and chemical stability. This study aims to fully understand the characteristics and application potential of TSP polycrystalline, and provide theoretical and experimental basis for its further development and application.

2. Preparation process of TSP polycrystalline

1. Raw material selection

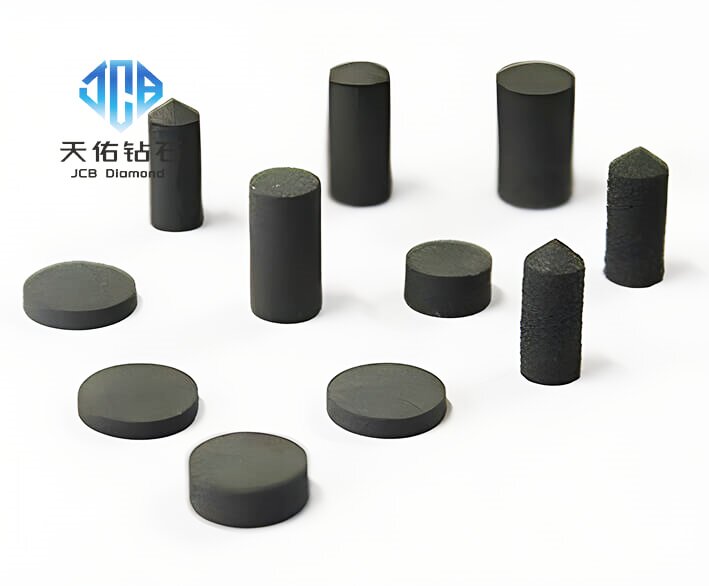

o High-purity diamond micropowder is usually selected as the main raw material, and its particle size distribution, purity and crystal morphology have an important influence on the performance of TSP polycrystalline. In addition, an appropriate amount of metal or ceramic binder needs to be added to promote the bonding between diamond particles and improve the overall performance of the material.

2. High temperature and high pressure synthesis method

o After the selected raw materials are evenly mixed, they are placed in a high temperature and high pressure device for synthesis. During the synthesis process, by precisely controlling the process parameters such as temperature, pressure and heat preservation and pressure holding time, the diamond micropowder is sintered and recrystallized under high temperature and high pressure to form a dense polycrystalline structure.

o Different combinations of process parameters will lead to differences in the microstructure, grain size and performance of TSP polycrystals. For example, increasing the synthesis temperature and pressure can help promote the fusion between diamond particles, but too high parameters may cause abnormal grain growth and affect the comprehensive performance of the material.

III. Microstructure of TSP polycrystals

1. Grain morphology and size distribution

o The microstructure of TSP polycrystals was observed and analyzed using scanning electron microscopy (SEM) and transmission electron microscopy (TEM), and it was found that it was composed of many small diamond grains tightly bonded. The grain morphology presents polygonal or irregular shapes, and the size distribution is relatively uniform, generally between a few microns and tens of microns.

o The size of the grain has a significant impact on the performance of TSP polycrystals. Smaller grain size helps to improve the hardness and wear resistance of the material, while larger grain size may be beneficial to improve the toughness and thermal conductivity of the material.

2. Grain boundary characteristics

o In TSP polycrystals, the grain boundary is one of the key factors affecting the performance of the material. There is a certain thickness of amorphous phase or transition phase at the grain boundary, which is mainly composed of binder and a small amount of impurity elements. These grain boundary phases not only play the role of connecting diamond grains, but also can alleviate the stress concentration inside the grains to a certain extent, thereby improving the overall strength and toughness of the material.

o The chemical composition and atomic structure of the grain boundary phase were further studied by analytical methods such as high-resolution TEM and electron energy loss spectroscopy (EELS), and it was found that it has a complex chemical bonding state and element distribution, which provides important clues for a deep understanding of the relationship between the performance and microstructure of TSP polycrystals.

IV. Performance characteristics of TSP polycrystals

1. Hardness and wear resistance

o The hardness of TSP polycrystals was measured by Rockwell hardness (HRA) and Vickers hardness (HV) test methods. The results showed that its hardness was as high as 90HRA or above, even close to the hardness value of natural diamond. In terms of wear resistance test, by comparing friction and wear experiments with traditional cemented carbide materials, it was found that the wear rate of TSP polycrystals was significantly lower than that of cemented carbide, showing excellent wear resistance.

o This high hardness and wear resistance are mainly attributed to the high strength of diamond grains in TSP polycrystals and the close bonding between grains, which enables the material to effectively resist surface damage and material removal when subjected to external friction and wear.

2. Thermal stability

o The thermal stability of TSP polycrystals in high temperature environments was studied using thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). The results show that TSP polycrystals can withstand high temperatures of up to 1000°C in air without significant oxidative decomposition reactions. This thermal stability is superior to most traditional engineering materials.

o The improvement in thermal stability is mainly due to the special grain boundary structure and chemical composition of TSP polycrystals. Certain elements in the grain boundary phase can form stable chemical bonds with the surface of diamond grains, inhibiting the erosion of oxygen atoms on diamonds at high temperatures, thereby ensuring the structural integrity and performance stability of the material under high temperature environments.

3. Chemical stability

o The TSP polycrystal samples were immersed in different acid and alkali solutions for chemical stability testing. After a long period of immersion, the chemical composition of the sample surface and the ion concentration in the solution were detected using analytical methods such as X-ray photoelectron spectroscopy (XPS) and inductively coupled plasma optical emission spectroscopy (ICP-OES). The results show that TSP polycrystals have good chemical stability in most acid and alkali solutions, and the surface composition and structure have not changed significantly, and the ion concentration in the solution has hardly increased.

o This excellent chemical stability makes it possible to use TSP polycrystals in harsh chemical environments such as chemical industry and oil extraction, providing an effective solution to the problems of corrosion and wear of traditional materials in these fields.

V. Application fields of TSP polycrystals

1. Oil and gas extraction field

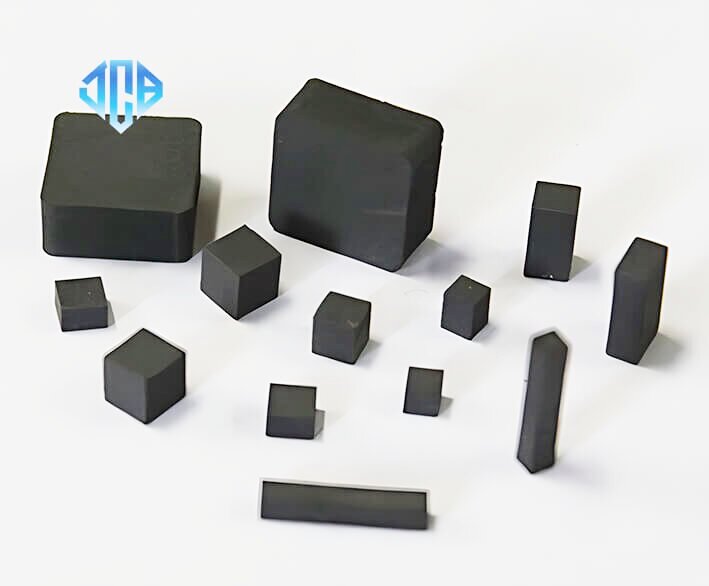

o In the process of oil and gas extraction, the drill bit needs to withstand harsh working conditions such as high temperature, high pressure, high hardness rock and corrosive media. TSP polycrystals are widely used in the manufacture of cutting teeth for oil drill bits due to their excellent hardness, wear resistance and chemical stability. Compared with traditional cemented carbide cutting teeth, TSP polycrystal cutting teeth can significantly improve the drilling speed and service life of the drill bit, reduce drilling costs, and improve oil and gas extraction efficiency.

2. Geological exploration field

o In the process of geological exploration, it is necessary to sample and analyze various types of rocks, which requires sampling tools to have high hardness, wear resistance and impact resistance. TSP polycrystals can be used to manufacture exploration tools such as geological drill bits and core tubes, which can effectively cope with the drilling and sampling of hard rocks, ensure the smooth progress of exploration work, and improve sampling quality and efficiency.

3. Mechanical processing field

o In metal cutting, stone processing, wood processing and other industries, the performance of the tool directly affects the processing quality and efficiency. TSP polycrystal tools have high hardness, high wear resistance and good cutting edge retention, which can achieve high-speed and high-precision cutting processing. They are suitable for processing various difficult-to-cut materials, such as high-hardness alloy steel, ceramics, composite materials, etc., and provide strong support for the development of modern manufacturing industry.

4. Electronic information field

o As electronic products develop towards miniaturization and high performance, the requirements for heat dissipation materials are getting higher and higher. TSP polycrystal has high thermal conductivity and good thermal stability. It can be used as a heat dissipation substrate or heat sink material for electronic devices, effectively dissipating the heat generated by electronic devices, ensuring the normal working temperature of electronic devices, and improving their reliability and service life.

VI. Problems and challenges in TSP polycrystal research

1. High preparation cost

o At present, the preparation process of TSP polycrystal mainly relies on high temperature and high pressure equipment and high-purity raw materials, which leads to relatively high preparation cost and limits its large-scale industrial application and market promotion. Therefore, how to reduce the preparation cost, optimize the preparation process, and improve production efficiency are the primary issues facing the research and industrial development of TSP polycrystalline materials.

2. Performance uniformity needs to be improved

o In the preparation process of TSP polycrystalline, due to the influence of factors such as the uniformity of raw material mixing, fluctuations in process parameters, and the uneven distribution of temperature and pressure inside the equipment, the prepared TSP polycrystalline materials have certain differences in performance, that is, the performance uniformity is poor. This will bring certain technical challenges to some application fields that require high consistency of material performance, such as electronic chip heat dissipation substrates, and further improve the preparation process and control methods to improve the performance uniformity and stability of the material.

3. Optimization of interface bonding strength

o Although there is a certain bonding force between the diamond grains and the grain boundary phase in TSP polycrystalline, under certain extreme working conditions, such as high-speed cutting and high impact loads, cracking, peeling and other failure phenomena may still occur at the grain boundary, indicating that the bonding strength of the grain boundary needs to be further improved. How to enhance the interfacial bonding strength between diamond grains and grain boundary phases and improve the overall performance and reliability of TSP polycrystalline materials by optimizing the binder composition and improving the sintering process is an important direction of current research.

VII. Conclusion and Prospect

1. Conclusion

o This study systematically studied and analyzed the preparation process, microstructure, performance characteristics and application fields of TSP polycrystalline. The results show that TSP polycrystalline, as a new type of material with excellent comprehensive performance, has excellent performance in hardness, wear resistance, thermal stability and chemical stability, and has broad application prospects in many fields such as oil and gas extraction, geological exploration, mechanical processing and electronic information.

o However, the research and application of TSP polycrystalline materials are still facing some problems and challenges, such as high preparation cost, poor performance uniformity and the need to improve the interfacial bonding strength, which need further in-depth research and technological innovation to solve.

2. Prospect

o With the continuous progress of materials science and technology and the in-depth research, it is expected that the preparation process of TSP polycrystalline will be continuously optimized and innovated in the future, the preparation cost will gradually decrease, and the performance uniformity and stability will be significantly improved. At the same time, through compounding or functional modification with other materials, it is expected to develop more TSP polycrystalline-based composite materials with unique performance and application value, further expanding its application field and market space.

o In theoretical research, there will be a deeper understanding of the relationship between the microstructure and performance of TSP polycrystalline. With the help of computer simulation and artificial intelligence technology, the microstructure and performance of TSP polycrystalline can be designed and regulated more accurately, providing a more solid theoretical foundation and technical support for its development in the field of high-performance materials.