The opening suspense: a smart tool to break through the “forbidden drilling zone”.

In the ultra-deepwater blocks of the Gulf of Mexico, where conventional drilling bits frequently fail due to high temperature and pressure, the Schlumberger NeoSteer system performs “miraculous operations” - controlling the well inclination angle with 0.1° precision and completing the 6,243-meter complex section in a single drilling trip! How does this “turning” drill break through the technological ceiling?

First, the slope revolution:

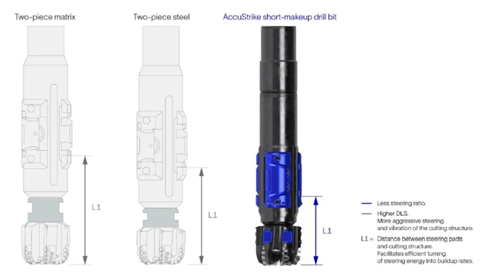

How does AccuStrike realize the “100-meter sharp turn”?

Technological breakthrough:

The AccuStrike's “Ultra-Short Connection” design compresses the distance between the blade and the guide system to 18 inches, which is 60% shorter than conventional tools. This structure reduces the delay in transmitting hydraulic thrust from 15 minutes to 3 minutes. In the Texas Shale, the drill completed a 45° slope adjustment in just 6.5 hours, compared to three trips with conventional tools.

Mechanics:

The short joint structure increases the bit's effective slope-making force to 12kN, which is equivalent to completing a U-bend over a distance of 100 meters. In Brazil's sub-salt fields, this capability has helped operators bypass salt dome formations and avoid $8 million worth of sidetrack drilling operations.

Industry standards rewritten:

Schlumberger's public test video shows the AccuStrike drilling continuously for 200 hours at a 12°/100ft build slope with only 3.2mm of cutter flank wear, far exceeding the requirements of the API RP 7G standard. This marks the entry of drilling in large curvature section into the era of “single trip drilling”.

Rock chip killer:

How does CenterFlow increase drilling speed by 27%?

Hydraulic design:

The CenterFlow's central flow channel occupies 60% of the bit's flow area, creating a high-speed jet that directly impacts the bottom of the well. In Iraqi carbonate formations, this design reduced the retention time of rock chip particles from 8.3 seconds to 2.1 seconds, and the incidence of mud packs from 23% to 4%.

Transboundary inspiration:

Engineers revealed that the center runner design was inspired by rocket engine nozzles. Through the conical acceleration structure, the mud flow rate reaches 45m/s at the outlet of the runner, which is equivalent to 1.5 times of the hurricane wind speed. This “violent rock clearing” method is particularly effective in hard ground.

Economy chain:

CenterFlow reduced the number of drill starts from four to two per well, saving $740,000 in rig day costs alone. More critically, fewer drill starts means less risk of wall instability - which in one high-temperature, high-pressure well in the North Sea directly prevented a $12 million well control incident.

Third, extreme challenges:

-40°C Arctic to 165°C Geothermal Survival Code

Material Science and Technology:

The drill bit matrix adopts nanocrystalline tungsten carbide, whose grain size shrinks from 5 μm of traditional materials to 200 nm, and its flexural strength is raised to 4,800 MPa. In the Alaskan Arctic Circle, this material maintains 95% toughness in the -40°C impact test, while the traditional material will plummet to 60%.

Geothermal well breakthrough:

At the Hellisheiði geothermal field in Iceland, the drill bit withstood 165°C and acidic fluid corrosion and still completed 1,200 meters of footage. Comparative tests showed that it lasted three times longer than the competition, thanks to the “self-sharpening” design of the polycrystalline diamond cutting teeth - which continue to expose fresh cutting edges during wear.

Insights from global performance:

The Schlumberger Application Map shows that its bits have set records in 37 “no-drill zones” around the world:

- Ultra-deep water under salt in Brazil: 8,000-meter horizontal section completed in a single pass.

- Sichuan Shale Gas, China: 55% increase in mechanical drilling speeds

- Siberia, Russia: 70% increase in drilling efficiency in the cold zone.

These cases prove that extreme environments are no longer off-limits to technology, but a stage to show engineering strength.

Conclusion: From “tool” to “solution”.

Schlumberger has redefined efficient well construction with its “Smart Drill + Digital Ecology”, as its slogan says: “It's not about drilling faster, it's about drilling smarter.” Follow us to unlock more energy technology wonders!