Electrodischarge machining - highly concentrated pulse discharge energy and powerful discharge explosion force melt the metal in the PCD material, graphitize and oxidize some diamonds, and some diamonds fall off, with good processability and high efficiency

Ultrasonic machining - low processing efficiency, large consumption of diamond micropowder, and large dust pollution

Laser machining - non-contact machining, high efficiency, small processing deformation, and poor processability

Among the above processing methods, electrodischarge machining has the best effect. The presence of bonding bridges in PCD makes electrodischarge machining of composite sheets possible.

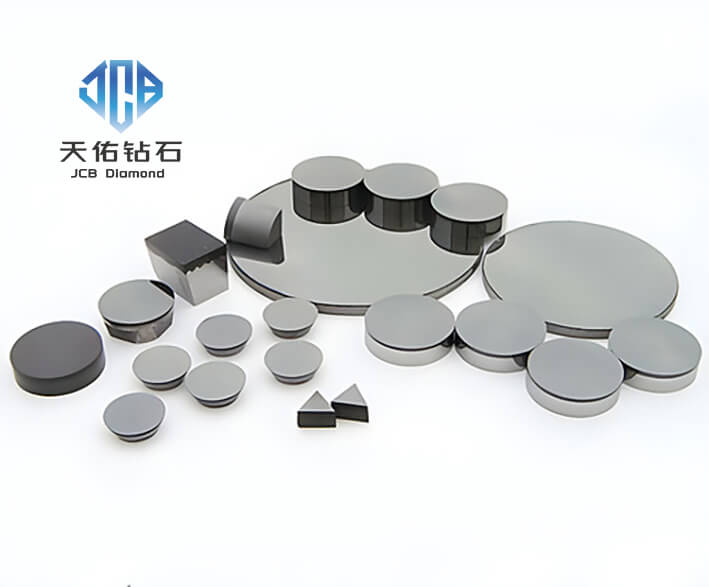

Under the condition of working fluid, pulse voltage is used to form a discharge channel for the working fluid near the electrode metal, and discharge sparks are generated locally. The instantaneous high temperature can melt and fall off the polycrystalline diamond, thereby forming the required triangular, rectangular or square tool head blank.

The efficiency and surface quality of EDM PCD composite sheets are affected by factors such as cutting speed, PCD particle size, layer thickness and electrode quality. The reasonable selection of cutting speed is very critical. Experiments show that increasing the cutting speed will reduce the surface quality of the machined surface, while too low a cutting speed will produce the "arch wire" phenomenon and reduce cutting efficiency. Increasing the thickness of the PCD blade will also reduce the cutting speed.