Research Background

High-power lasers with high beam quality have widespread applications in space exploration, high-energy physics, and national defense security. Using a large gain medium allows for a larger gain volume and greater thermal management flexibility. However, due to limitations in the energy storage capacity and thermal properties of the gain medium, while population inversion lasers achieve increased laser power using larger crystals, increasing the size of conventional crystals cannot completely address the thermal effects caused by heat accumulation.

Diamond, due to its excellent thermal conductivity, high damage resistance, and chemical inertness, is widely considered an ideal material for high-energy laser technology. Furthermore, as a nonlinear crystal, diamond exhibits significant potential for nonlinear optical conversion due to its ultra-high Raman and Brillouin gains, giving it unparalleled advantages in achieving high-power, high-beam-quality laser output. Currently, researchers have achieved high-power output in the kilowatt range with steady-state power and megawatt-level peak power using diamond crystals with apertures as small as square millimeters (mm²).

Research Content

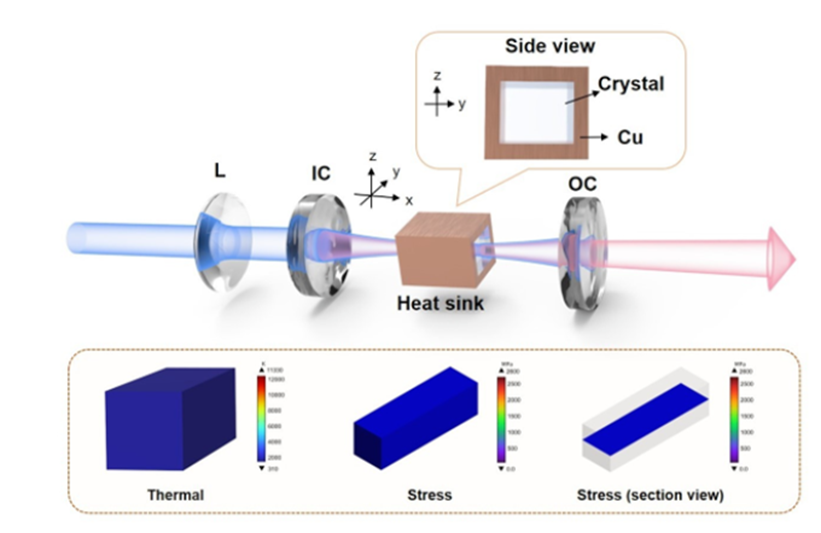

Recently, the Diamond Laser Technology and Applications Team, led by Professors Bai Zhenxu and Lü Zhiwei of Hebei University of Technology, detailed the critical impact of diamond crystal size on high-power laser output performance from a cutting-edge perspective on high-power diamond laser development. Based on photothermal analysis and recent advances in diamond crystal growth technology, the team proposed that large-sized diamond crystals will open up a new frontier in high-power laser development. The study demonstrated the temperature and stress distributions of diamond crystals by establishing a thermal analysis model based on a common end-pumping structure (Figure 1). Comparisons of the temperature and stress distributions of diamond crystals of varying sizes with those of traditional inverse particle crystals and traditional Raman crystals under high thermal loads demonstrated that large-sized diamond crystals can significantly mitigate thermal effects, further enhancing the performance of high-power lasers.

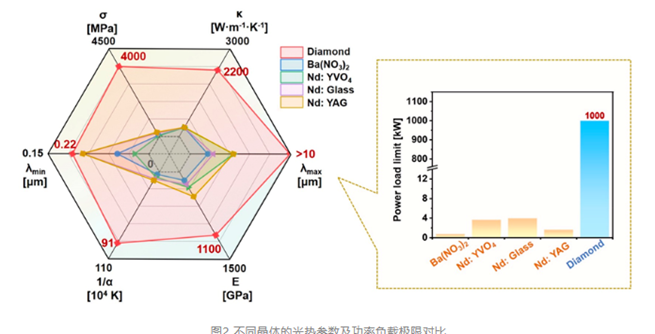

The authors also conducted an in-depth analysis of the power load limits of diamond crystals under end-pumping conditions. Comparing these with common laser crystals (such as Nd:YAG and Nd:YVO₄) and Raman crystals (such as barium nitrate), the study found that these other crystals, due to material limitations, tend to reach melting points or fracture limits under high power loads. However, diamond, due to its superior thermal conductivity and heat resistance, significantly outperforms these other crystals by 2-4 orders of magnitude. Figure 2 visually illustrates the photothermal properties of various materials and their corresponding power load limits, providing strong evidence for the unique advantages of diamond crystals in high-power laser applications.