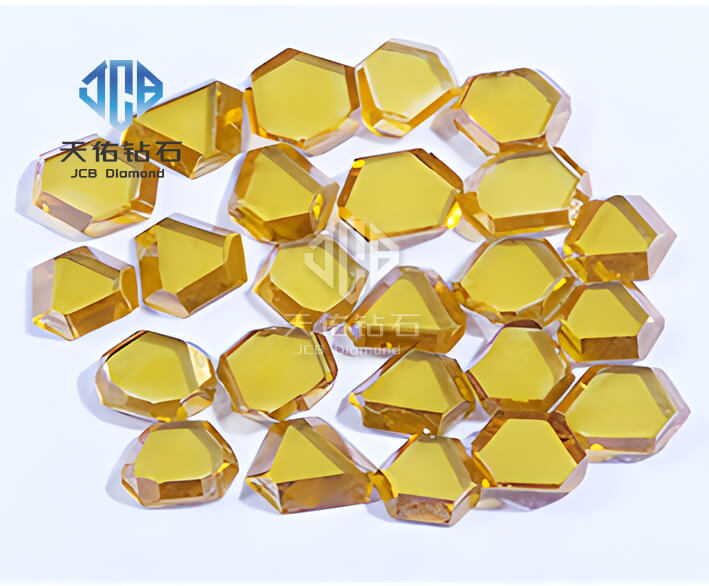

Glass processing

Glass processing involves grooving, cutting, chamfering, drilling, edging, grinding, polishing and other processes, all need to use diamond tools, such as: resin grinding wheel, drill, grinding head, grinding wheel, polishing wheel, grinding fluid, etc., and these diamond tools are inseparable from our diamond, so we can according to the specific needs of customers, to help customers develop the most suitable solutions.

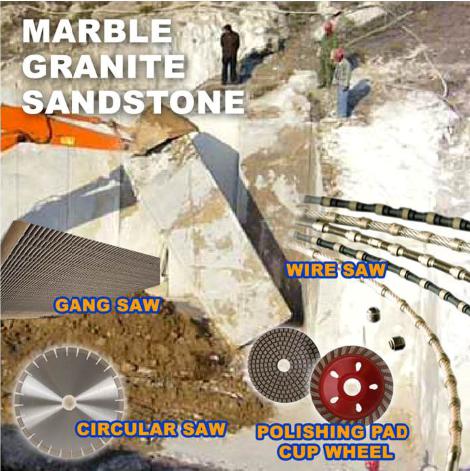

Stone processing

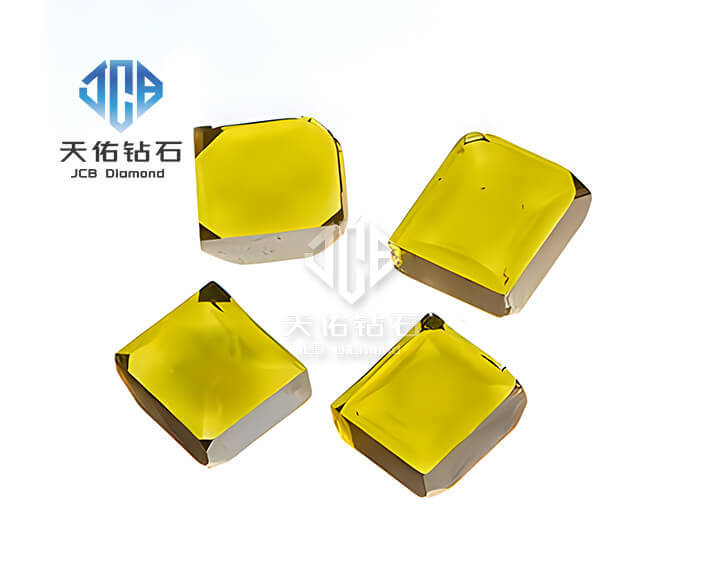

In order to maximize the potential needs of our customers, we offer not only high-end coated JSD diamonds for increased holding power and tool life, but also a wide range of synthetic diamond products in different strength and particle size to meet the needs of our customers for higher performance and lower production costs, as well as the opportunity to develop new end-user applications, so that our customers gain a competitive advantage in the market.

Our cutting blade solutions for construction and stone

More durable cutting materials mean lower costs for the tool and the end-user manufacturer, and the incremental increase in productivity can help customers improve the performance of finished tools and reduce tool manufacturing costs.

We have successfully developed more holding JSD synthetic diamond abrasives with excellent thermal stability to deal with a variety of hardness aggregates, products for sawing, cutting, grinding, polishing, foundation drilling, trenching, partition cutting, tunnel digging and soil reinforcement.

Our stone and concrete polishing solutions

In order to meet the aesthetic requirements of consumers, the stone industry needs to further polish and polish the board after cutting. The special powder of metal binder grinding block provided by us has the characteristics of good sharpness, long life and high work efficiency. It is widely used in the efficient grinding and polishing of non-metallic hard and brittle materials such as terrazzo floor, marble, granite, firebrick, terrazzo and concrete products.

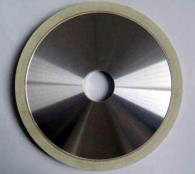

Ceramic industry

| Our ceramic solution is to provide customized metal binders, resin binders, ceramic binder powders and related coating products. In the general grinding, you can choose 80-120 mesh, semi-fine grinding choose 120-180 mesh, fine grinding choose 180-mesh -W40, resin binder grinding tool choose 50%-100% concentration, bronze binder grinding tool choose 75%-150% concentration, coarse particle size, shape grinding and high efficiency grinding should choose high concentration. | |

| Metal binder is mainly used for rough grinding, resin binder is mainly used for fine grinding, ceramic binder diamond grinding wheel has high strength, good heat resistance, sharp cutting, high grinding efficiency, it is not easy to heat and clog during grinding, and the amount of thermal expansion is small to control the processing accuracy. Compared with resin bonded grinding wheel, it solves the problems of low life of resin diamond grinding wheel, low grinding efficiency, and the abrasive tool itself is changeable in the grinding process. |

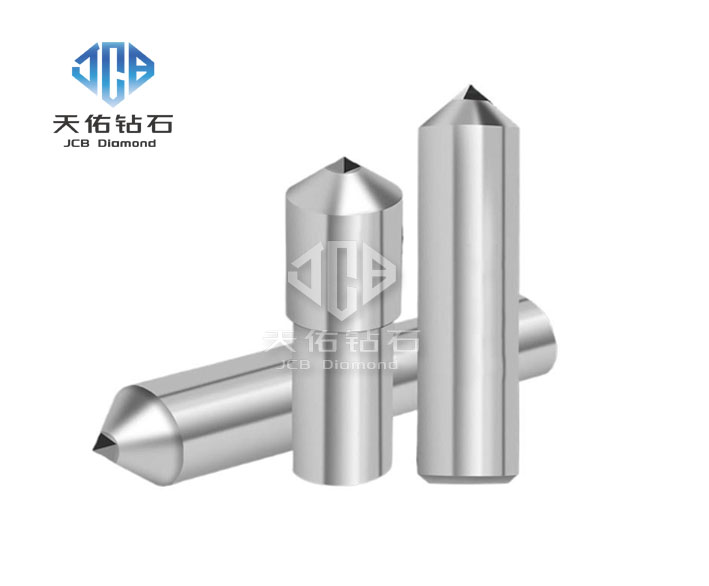

Our JSD diamond coarse material is widely used in the manufacture of diamond saw blades and rope saws for cutting stone, reinforced concrete and other building materials; JMD diamond fine material is widely used in the manufacture of diamond saw blades and bits for cutting glass, ceramics and other building materials. Diamond crushing material is widely used in the manufacture of diamond grinding tools for grinding stone, glass, ceramics and other building materials.