Diamond composite sheet is a composite material composed of diamond and cemented carbide matrix. It has the characteristics of high hardness and good wear resistance. It is widely used in oil drilling, geological exploration, coal drilling and mining drill bits and mechanical processing tools.

Common testing items for diamond composite sheets include: cobalt removal depth, impact toughness, internal defects, wear ratio, carbide magnetic saturation, coercive force, etc.

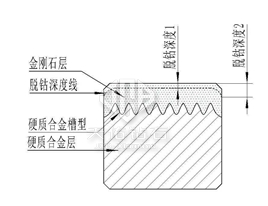

1. Cobalt removal depth

When polycrystalline diamond composite sheet (PDC) is working, it may be converted into graphite under the catalytic action of residual cobalt elements inside, causing the composite sheet to fail. To improve the performance of PDC, people often use strong acids and strong oxidants to remove residual catalysts in PDC. Therefore, the cobalt removal process is a very important link in the production of composite sheets. Grinding tests show that the significant improvement of the product's wear resistance is directly determined by the cobalt removal depth. Commonly used detection methods are: 1. Scanning electron microscope detection of composite sheet cross-section; 2. X-ray fluoroscopy.

2. Impact toughness

PDC is a drill bit tooth, and is subject to great impact during the drilling process. Impact toughness reflects the comprehensive index of the toughness and bonding strength of the composite sheet, and is a key indicator for evaluating the use effect of the composite sheet.

Dart impact method: 1. Large-scale destructive impact; 2. Small-scale fatigue impact.

3. Internal defects

Since PDC products are generally produced in large quantities and repeatedly, each piece of product is synthesized under the same macroscopic conditions. Therefore, there must be a certain dispersion and difference in performance between each piece of product, resulting in some defects in the product, which will affect the yield of the product. Internal defect detection also reflects the quality of different batches of products.

Ultrasonic C scanner (water immersion ultrasonic pulse reflection method)

4. Wear ratio

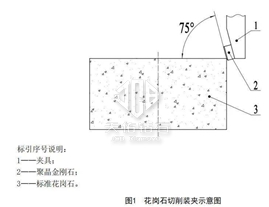

Polycrystalline diamond composite sheet (PDC) is widely used in fields such as drilling and cutting. In its application process, the level of wear resistance is a very important technical indicator. For a long time, people have conducted a lot of exploration on the detection method of PDC wear resistance. Commonly used detection methods are: 1. Universal tool grinder detection method; 2. Vertical lathe granite detection method.