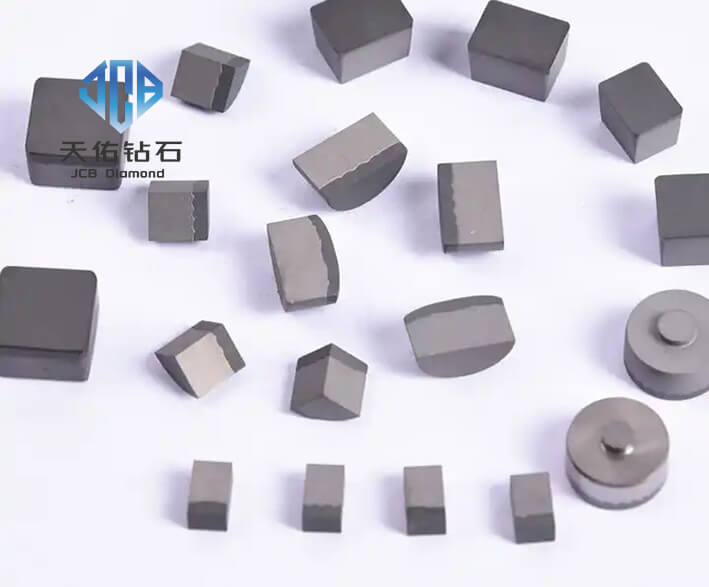

Polycrystalline diamond compact (PDC) is a superhard composite material made of diamond powder as raw material and WC cemented carbide as matrix, sintered under high temperature and high pressure conditions through a specific synthesis process.

Compact sheets have the advantages of high hardness and good wear resistance of diamond and strong impact resistance of cemented carbide. They have been expanded from deep well drilling to various fields such as mineral exploration and mechanical processing. Wear resistance is an important characteristic of PDC use, generally characterized by the parameter of wear ratio. PDC manufacturers are trying their best to improve its wear resistance.

However, since there are many factors that affect the wear resistance of PDC, and each factor restricts each other, there are still some problems in further improving the wear resistance of PDC.

Polycrystalline diamond composite sheets have both the extremely high wear resistance of polycrystalline diamond and the high impact resistance of cemented carbide. The diamond layer has a sharp and self-sharpening edge, which can always keep the cutting edge sharp. Therefore, it is very suitable for exploration of soft to medium-hard formations in petroleum and geological drilling, and the effect is very good.

The diamond content in the polycrystalline diamond composite sheet is as high as 99%, so the diamond layer has extremely high hardness and excellent wear resistance. Its Rockwell hardness is 6.5104~7.0104MPa, or even higher.

The cemented carbide matrix overcomes the shortcomings of polycrystalline diamond being hard and brittle, and greatly improves the overall impact toughness of the product.

The easy weldability of cemented carbide solves the problem that polycrystalline diamond is difficult to combine with other materials by welding, and can make the polycrystalline diamond composite sheet vertically welded on the drill bit.