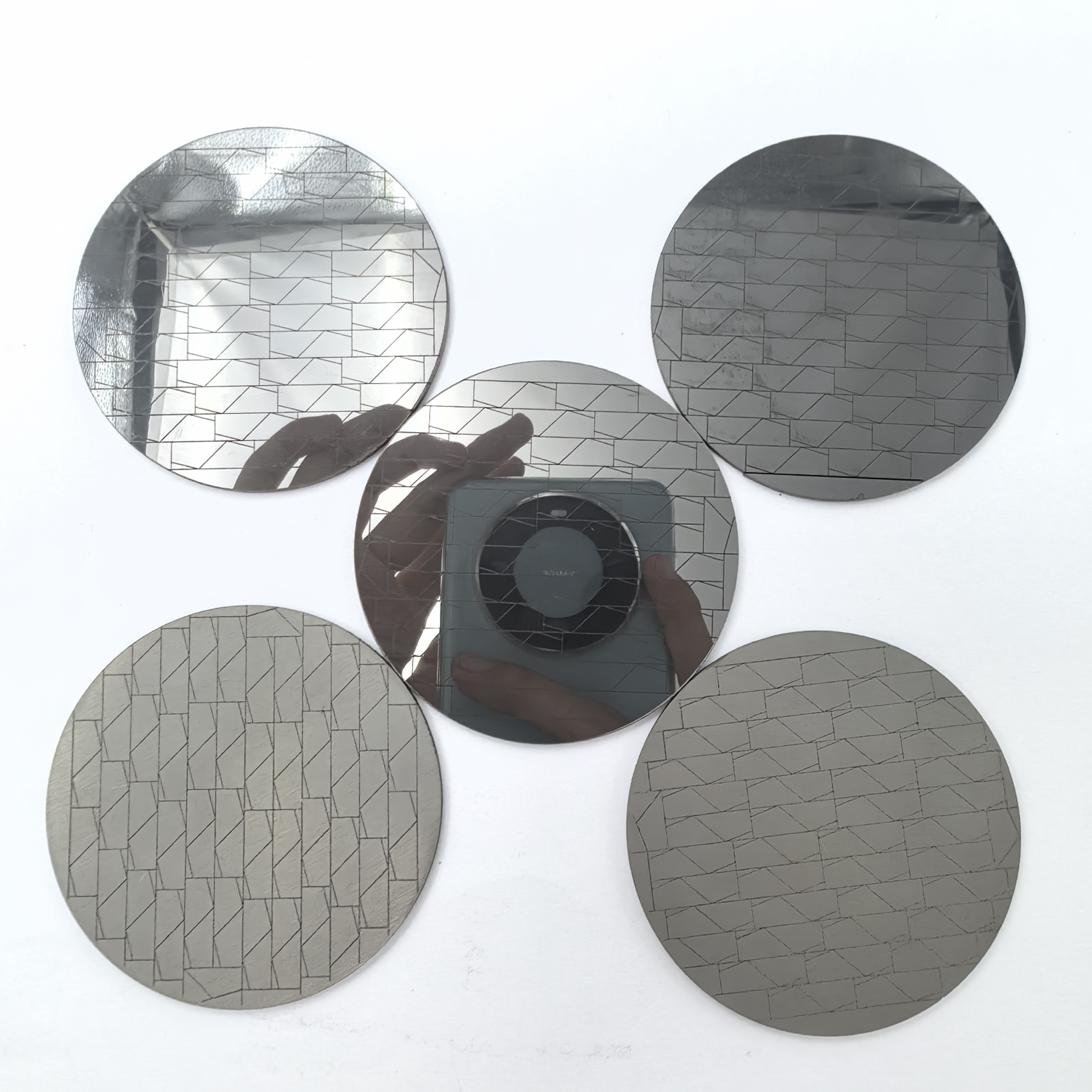

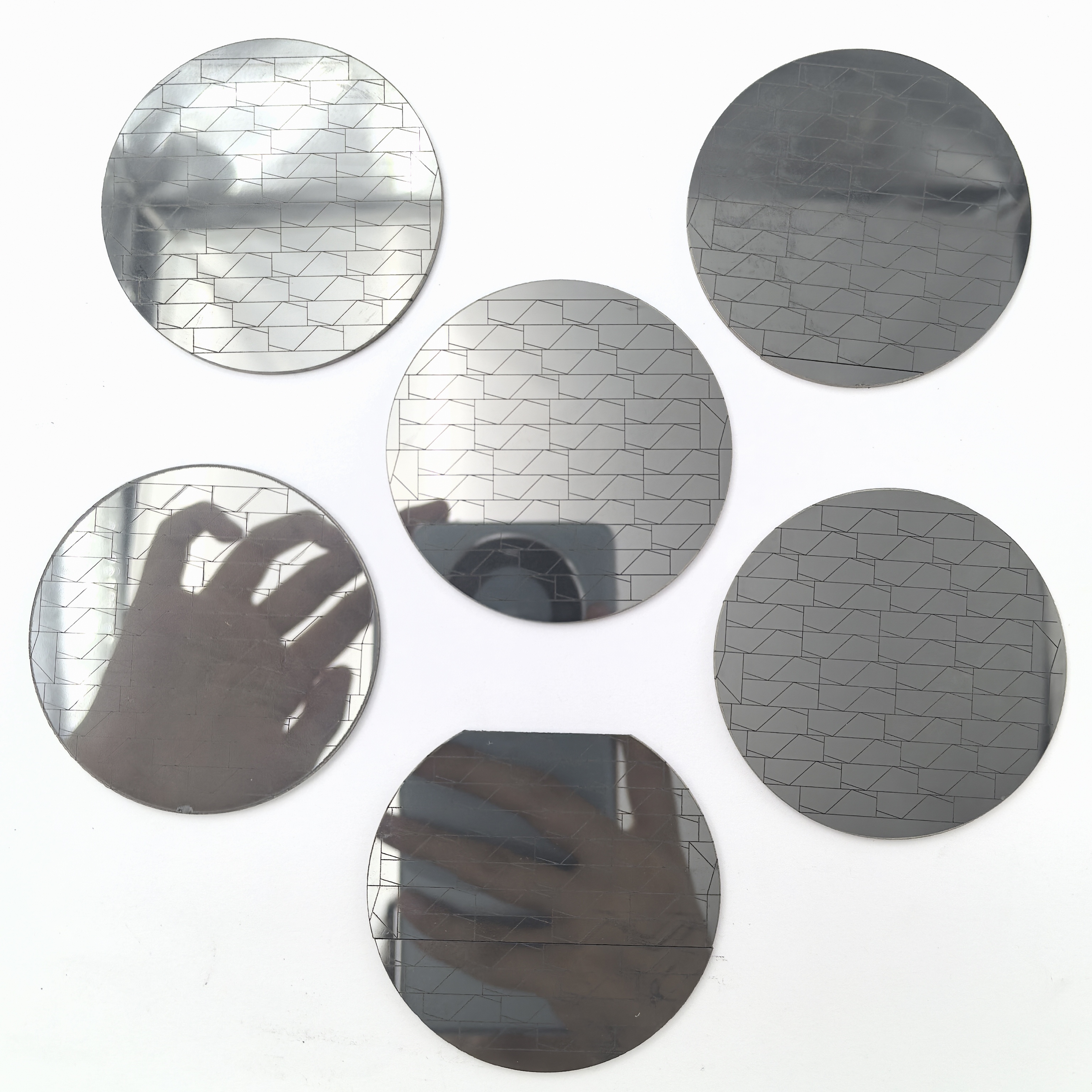

This batch of goods has been shipped to France

I. Machining and Cutting Tools (Major and Widest Application)

This is where PCD tools shine, primarily for efficient and high-precision machining of non-ferrous and non-metallic materials.

1. Automotive Industry:

o Engine Parts: Machining aluminum alloy cylinder blocks, cylinder heads, pistons, crankcases, etc. This is the largest area for PCD tool use.

o Wheel Hubs: Precision turning and milling of aluminum alloy wheels.

o Transmissions: Machining transmission housings (typically aluminum or magnesium alloys).

o Braking Systems: Machining brake discs (although cast iron is a ferrous metal, brake discs often have high-silicon aluminum alloy components, making them suitable for PCD machining).

2. Aerospace Industry:

o Machining numerous high-strength aluminum alloy, magnesium alloy, carbon fiber composite (CFRP), and glass fiber composite (GFRP) components on aircraft. PCD tools effectively handle the highly abrasive nature of these materials, with a lifespan far exceeding that of carbide tools.

3. 3C Electronics Industry:

o Processing of aluminum and magnesium alloy casings and frames for mobile phones and computers.

o Precision milling of ultra-hard and brittle materials such as optical components and sapphire glass cover plates.

4. Wood Processing and Wood-Based Panel Industry:

o Planers and milling cutters used in the production of high-end particleboard, medium-density fiberboard (MDF), and oriented strand board (OSB). PCD tool life is over 100 times that of carbide, maintaining a sharp edge for extended periods and ensuring a smooth surface finish.