I. Core Manufacturing Process: Pressureless Sintering Technology

Pressureless sintering is the key technology in manufacturing this cutting head. The process flow is as follows:

1. Batching and Mixing: Precisely measured synthetic diamond particles are uniformly mixed with metal matrix powder (binder) in a mixer. Diamond provides superhard grinding points, while the matrix powder supports and encapsulates the diamond.

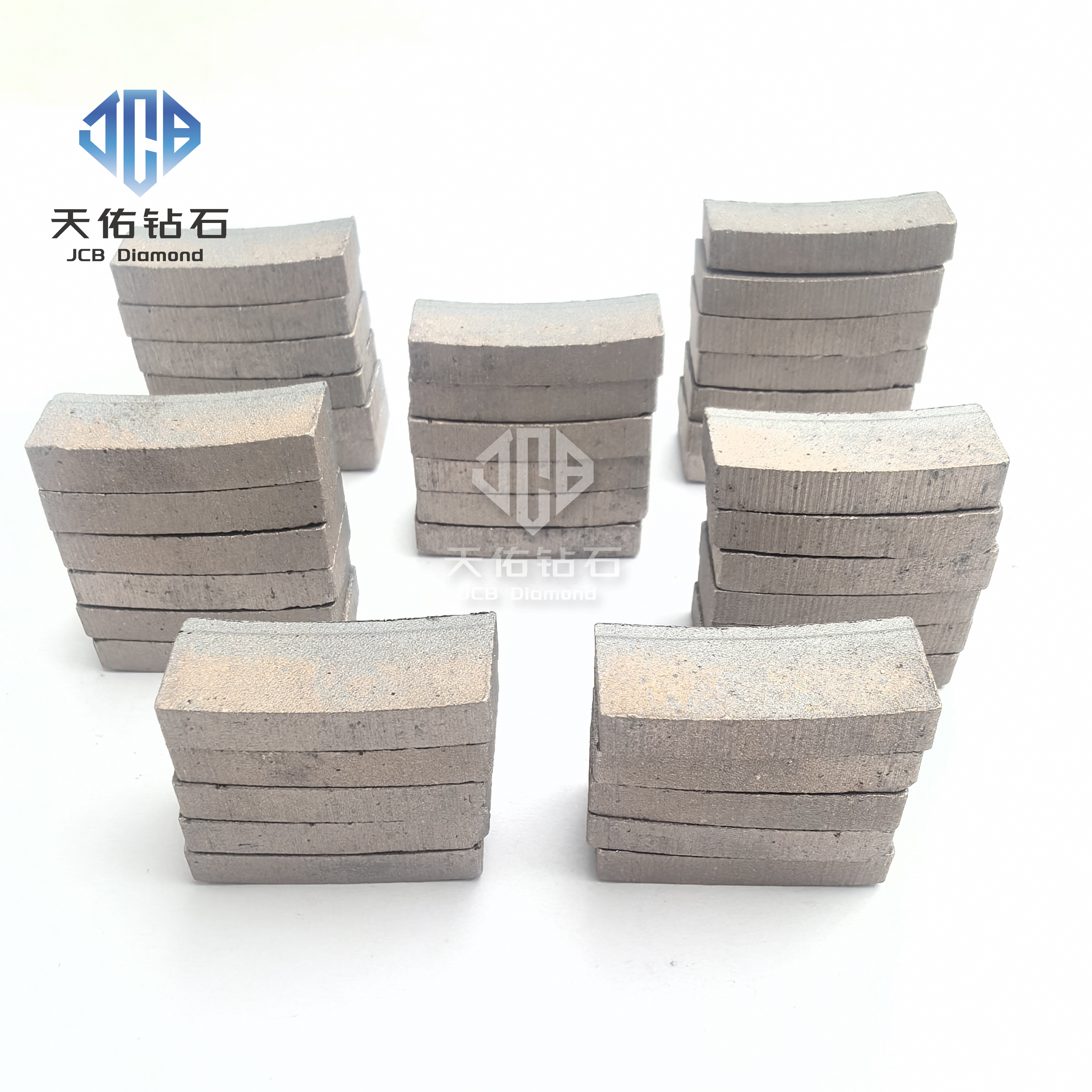

2. Cold Pressing: The mixed material is placed into a mold of a specific shape and pressed under high pressure at room temperature to form a cutting head blank with preliminary strength and a specified shape.

3. Pressureless Sintering: This is the core of the process. The cold-pressed blank is fed into a high-temperature sintering furnace with a protective atmosphere (such as hydrogen or argon). At high temperatures (below the melting point of the matrix metal), the matrix powder particles bond through atomic diffusion, flow, and migration. However, no external mechanical pressure is applied throughout the process; densification is achieved solely by the material's own sintering driving force, forming a robust alloy skeleton that firmly encapsulates the diamond.

4. Post-processing: After sintering, the cutting head undergoes slow cooling, necessary machining (such as sharpening and shaping), and quality inspection to obtain the final product.

Process advantages: Compared to hot-pressing sintering, pressureless sintering equipment is simpler, has higher production efficiency, and relatively lower costs. It also allows for better control of the cutting head's porosity, facilitating cooling and chip removal during cutting.

II. Product Features

1. Extremely high hardness and wear resistance: Diamond is the hardest known natural substance, giving the cutting head an extremely long service life and stable cutting performance.

2. Good self-sharpening: During cutting, the softer metal matrix wears moderately, continuously exposing new, sharp diamond particles, keeping the cutting head consistently sharp and preventing slippage or dulling.

3. High cutting efficiency: Capable of quickly cutting hard materials with a clean cut, significantly more efficient than ordinary abrasive tools.

4. Good heat dissipation: The unique sintering structure creates micropores that help contain chips and promote heat dissipation, reducing damage to the cutting head and the workpiece from high temperatures during operation.

5. Wide Range of Applications: By adjusting the matrix formula (such as hardness and wear resistance) and the concentration and particle size of diamond, customized production can be achieved to meet the cutting needs of different materials.

III. Main Application Scenarios Pressureless sintered diamond cutting heads are mainly used in the processing of hard and brittle materials such as stone, building materials, road construction, ceramics, and glass:

• Stone Processing: Welded onto circular saws, gang saws, and wire saws for cutting, grinding, and shaping granite, marble, artificial stone, and other stones.

• Construction Engineering: Installed on road cutters, wall saws, and floor milling machines for cutting, grooving, and demolishing concrete pavements, walls, and bridges.

• Building Material Processing: Used for cutting refractory bricks, ceramic bricks, asphalt pavements, etc.

• Jade Processing and Exploration: Used in specialized fields such as jade cutting and geological drilling.