Thermally Stable Polycrystalline Diamond (TSP) represents a groundbreaking advancement in superhard materials technology. Through innovative material design and manufacturing processes, it effectively addresses the industry-wide challenge of performance degradation in high-temperature environments that has long plagued conventional superhard materials. This remarkable material not only preserves the inherent extreme hardness and wear resistance of diamond but also achieves comprehensive performance enhancement through unique structural design, offering innovative solutions for modern industrial processing.

The exceptional properties of TSP originate from its distinctive microstructure and manufacturing methodology. Unlike conventional polycrystalline diamond, TSP undergoes complete elimination of metal catalysts during production, resulting in a pure diamond-to-diamond bonding architecture. This unique configuration provides unparalleled stability in elevated temperature conditions, maintaining crystalline integrity where traditional PCD materials would suffer from cracking and delamination due to metallic phase expansion.

In terms of mechanical performance, TSP achieves an optimal balance between hardness and toughness through precise control of diamond powder size distribution and sintering parameters. With Vickers hardness exceeding 100 GPa and impact resistance improved by three to five times compared to single crystal diamond, this balanced performance profile enables TSP to withstand both continuous abrasive wear and operational impact loads, significantly expanding its application scope.

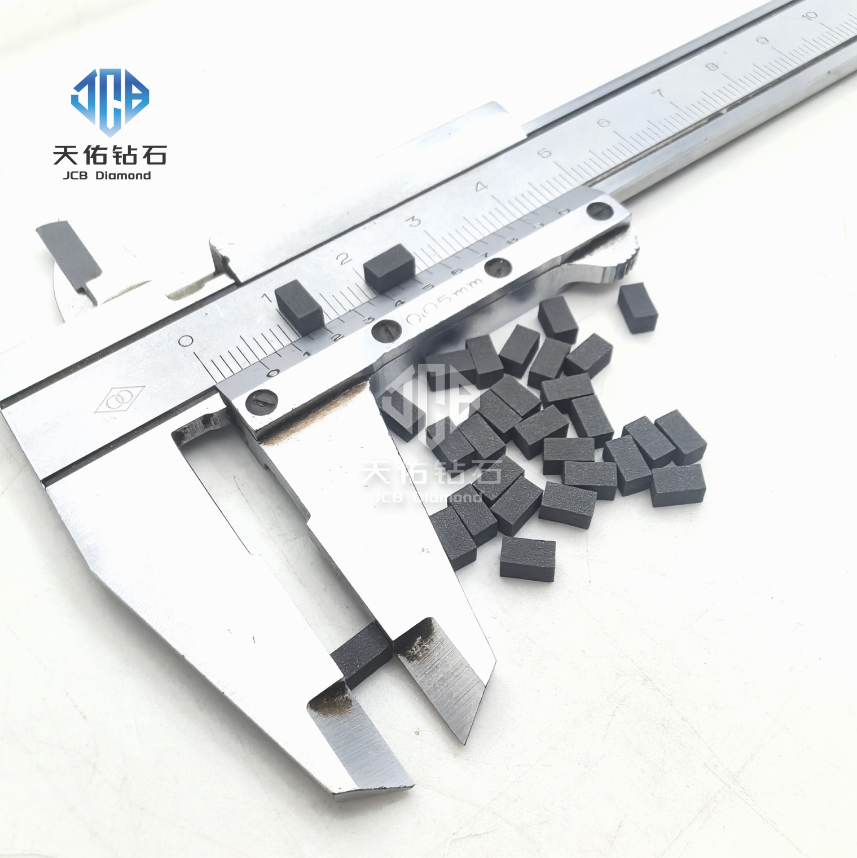

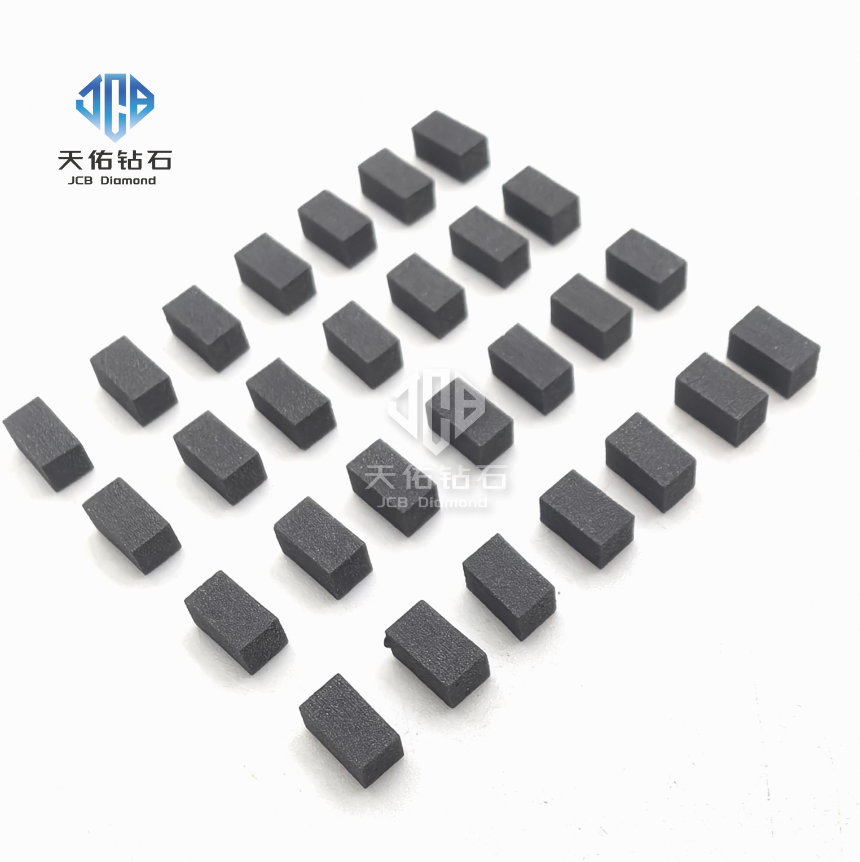

Manufacturing flexibility constitutes another major advantage of TSP. By adjusting production parameters, various specifications and geometries can be manufactured, ranging from standard cylinders and cubes to specially designed triangular prisms and arc-ended segments. This customization capability allows TSP to perfectly adapt to diverse tooling systems.

In the oil and gas drilling sector, TSP has become an indispensable critical material. Under extreme conditions such as deep-well and horizontal drilling, conventional tool materials often prove inadequate. TSP-engineered gauge protection elements and cutting inserts effectively challenge highly abrasive formations including conglomerate and quartzite. Field data demonstrates that TSP-enhanced drilling tools achieve average service life exceeding three times that of traditional carbide tools, with single-run penetration depth improved by approximately 40%, significantly enhancing drilling efficiency while reducing overall costs.

The precision manufacturing domain represents another important arena where TSP demonstrates exceptional capabilities. In high-technology industries including aerospace and automotive manufacturing, as new materials continue to emerge, processing difficulties correspondingly increase. For instance, when machining high-silicon aluminum alloy components, traditional tools rapidly deteriorate due to the highly abrasive silicon particles. TSP tools not only extend service life by five to eight times but also significantly improve surface quality, achieving surface roughness below Ra 0.1μm. In carbon fiber composite processing, the uniquely sharp cutting edges of TSP tools effectively reduce delamination and burring phenomena, improving product qualification rates.

The construction materials processing industry similarly benefits from TSP's superior properties. During natural stone processing including granite and marble, materials containing hard particles like quartz cause severe tool wear. TSP tools demonstrate exceptional wear resistance, maintaining sharp cutting edges under continuous processing conditions. For high-performance concrete widely used in modern construction, TSP drilling tools easily handle high-strength aggregates, achieving drilling efficiency improvements exceeding 200% compared to conventional tools, with substantially extended tool life.

TSP technology development maintains close alignment with industrial requirements. Recent breakthroughs in surface modification technologies have significantly enhanced the bonding strength between TSP and tool substrates. Advanced metallization coating technologies, including multi-component composite coatings and graded transition layer designs, have improved TSP brazing strength by over 40%, effectively resolving technical challenges in dissimilar material joining. This breakthrough substantially expands TSP's application range in composite tool structures.

As global industry advances toward intelligent and green development, TSP materials demonstrate enormous potential in emerging fields. In renewable energy, TSP tools are employed for ultra-precision machining of wind power bearings, ensuring precision and reliability of large-scale equipment. In semiconductor manufacturing, TSP precision cutting tools play increasingly important roles in wafer dicing processes. The electronics industry is also adopting TSP materials for micro-drills and precision molds, meeting development requirements for electronic device miniaturization and high-density integration.

Advancements in materials science continue to drive TSP technology innovation. Nanotechnology applications enable more uniform and compact microstructures with enhanced performance. Design concepts incorporating multilayer composite structures and functionally graded materials allow precise performance regulation in different sections of TSP tools. With increasingly mature manufacturing processes and continuous cost optimization, TSP materials are expanding from specialized applications to general industrial fields, providing robust support for manufacturing transformation and upgrading.