As the global wire processing industry shifts towards high-speed, high-precision, and low-cost production, polycrystalline diamond (PCD) wire drawing die inserts, as core tools, are undergoing profound transformations from material design to application scenarios. Compared to traditional carbide dies, PCD inserts offer a service life approximately 15–25 times longer, significantly reducing downtime for die changes and overall production costs. However, to meet the drawing demands of high-performance materials such as stainless steel and tungsten-molybdenum alloys, PCD, CVD diamond, and single-crystal diamond die inserts are forming a complementary landscape, continuously pushing the boundaries of industry technology.

PCD Die Inserts: Advantages in Technological Maturity and Large-Scale Applications

Material Structure and Performance Characteristics

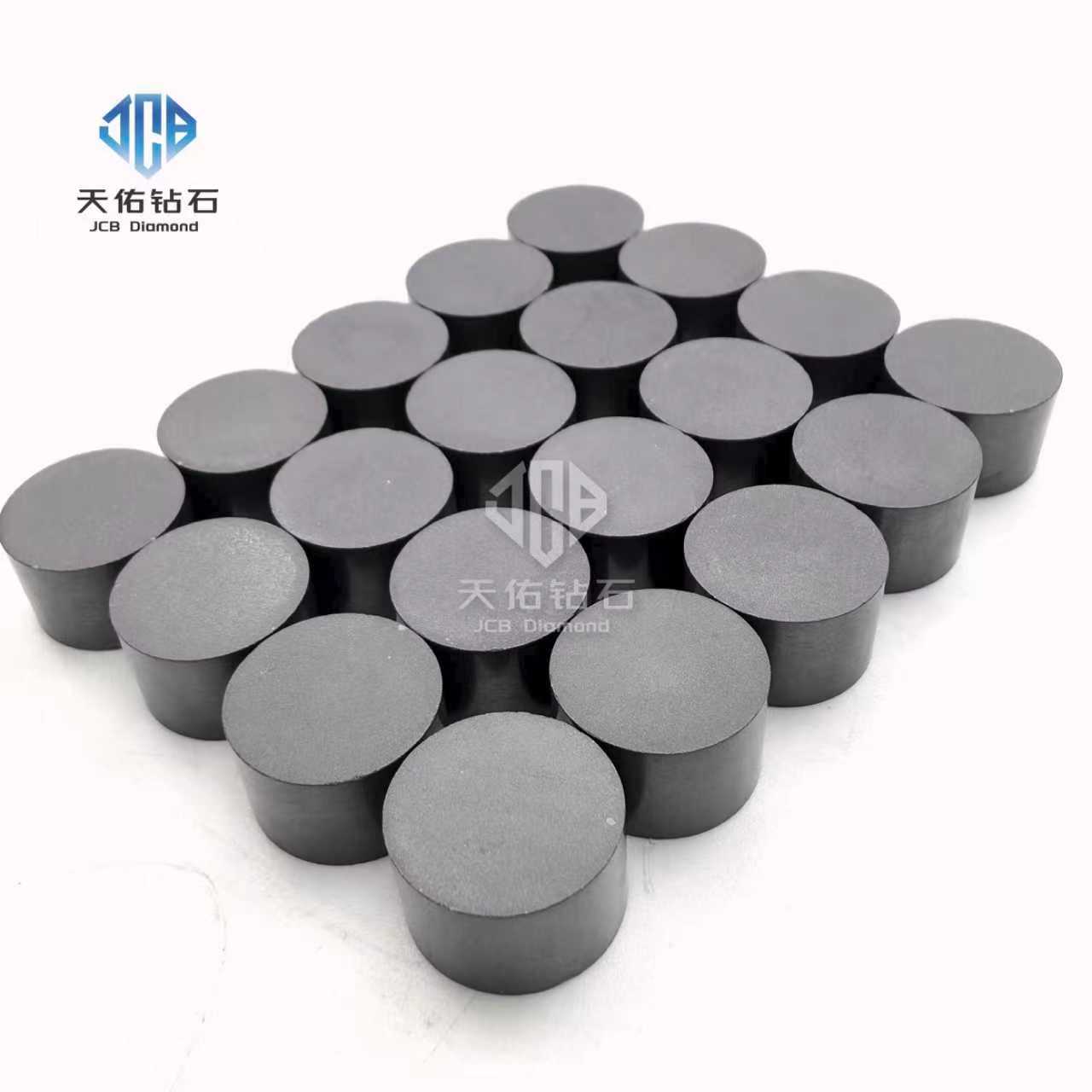

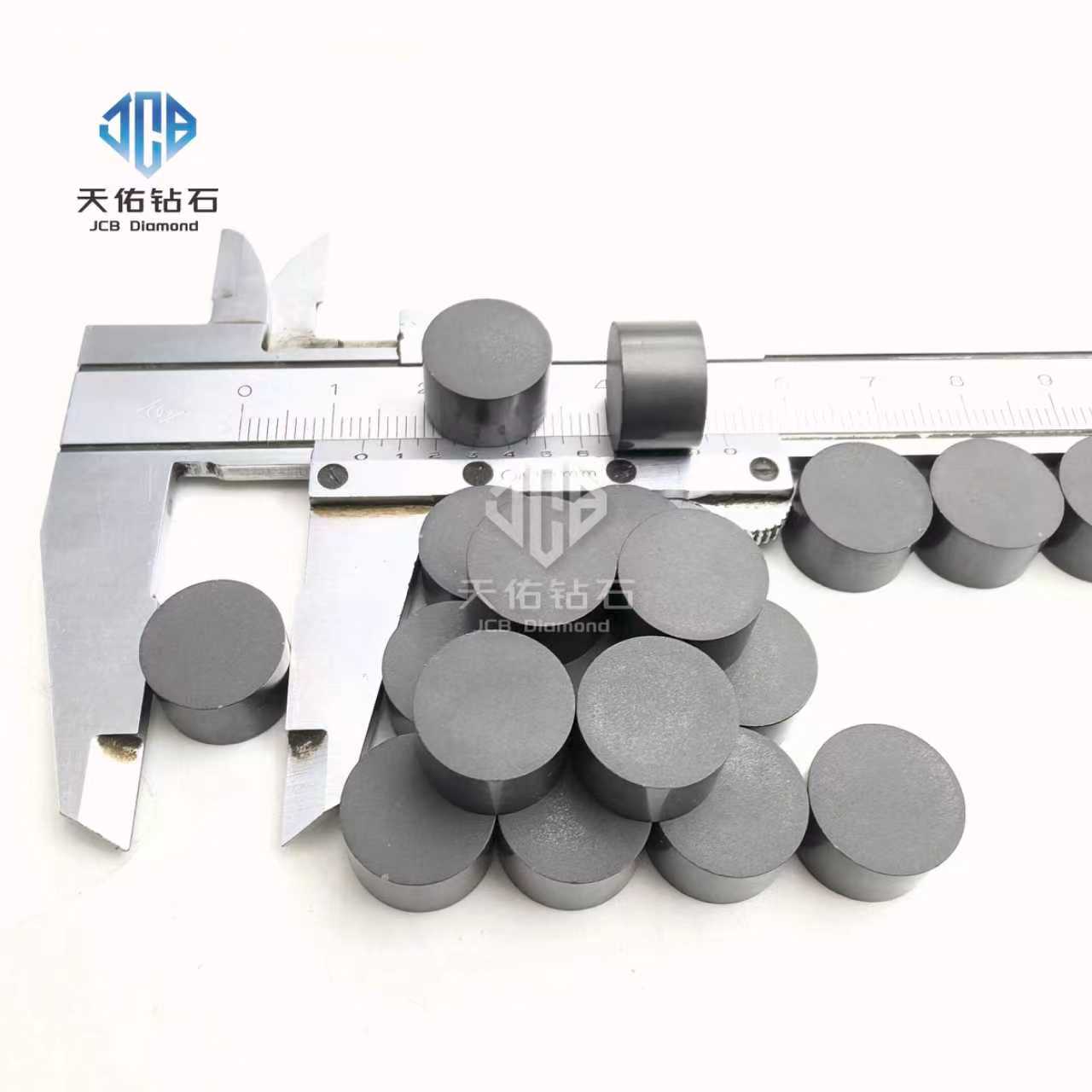

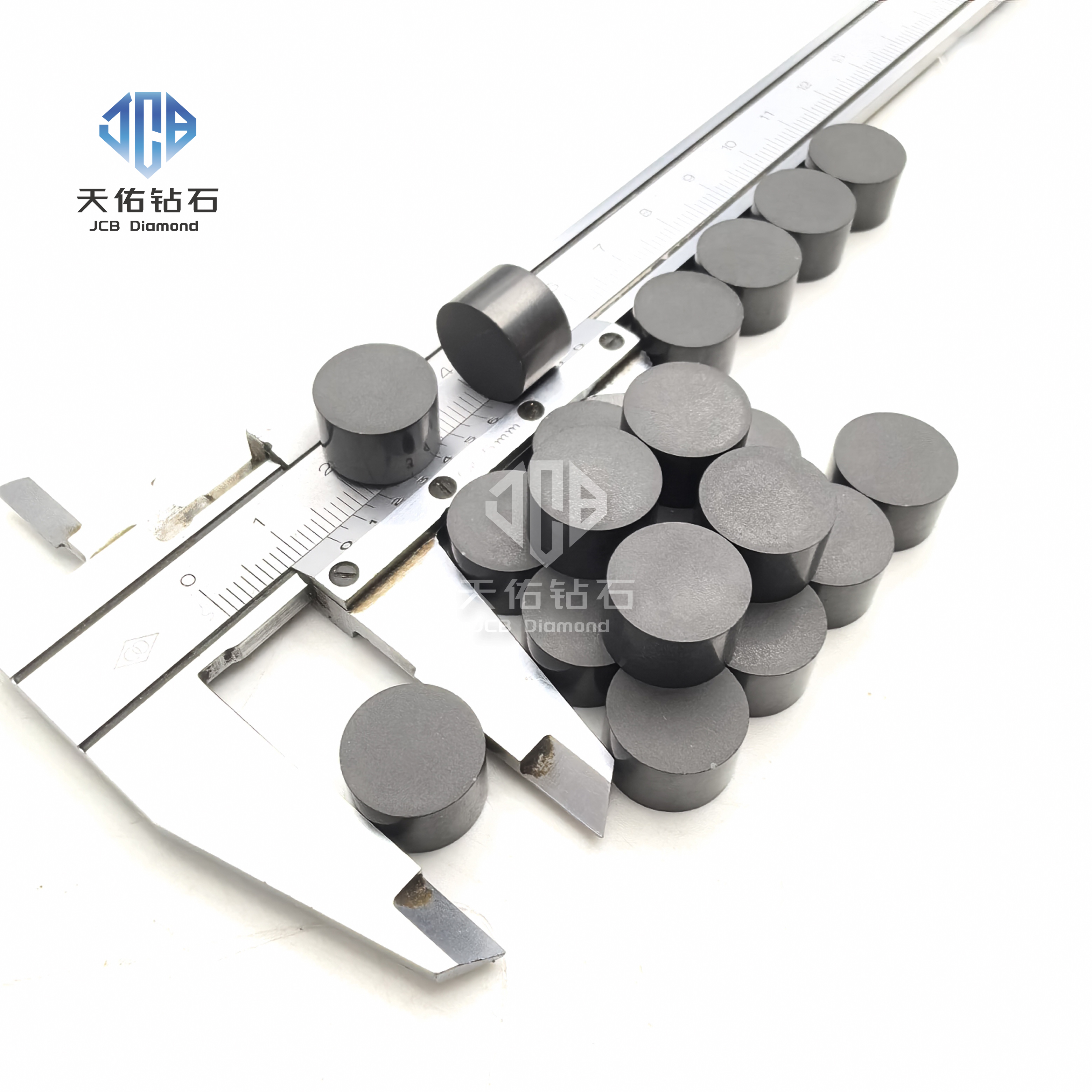

PCD die inserts are manufactured by sintering micron-sized diamond particles with a binder (cobalt or silicon-based) under high temperature and high pressure. Their macroscopic isotropy ensures uniform wear of the die hole, avoiding common defects like "ovalization" seen in single-crystal diamonds. Cobalt-based PCD, due to the presence of a metallic binder, can be efficiently processed using methods such as electrical discharge machining (EDM) and laser processing, but its temperature resistance is limited to below 650°C. Silicon-based PCD, through its metal-free design, achieves thermal stability at high temperatures up to 1000°C, albeit with higher processing difficulty.

Economic Efficiency and Application Scenarios

PCD die inserts cost only a fraction of single-crystal diamonds and far exceed the service life of carbide dies, making them the mainstream choice for high-speed drawing of non-ferrous metals like copper and aluminum. Current mainstream models can enhance surface polishing precision through optimized grain refinement technology, gradually replacing natural diamonds in medium-to-fine wire drawing applications.

CVD and Single-Crystal Diamond Die Inserts: Technological Breakthroughs in Niche Areas

CVD Diamond: Advantages in Purity and Thermal Management

Chemical Vapor Deposition (CVD) diamond grows under high-temperature and low-pressure conditions, containing no binder, and exhibits higher wear resistance, thermal conductivity, and corrosion resistance. Its aperture processing range can reach 0.02–1.0mm, making it suitable for drawing special materials such as stainless steel wire, tungsten wire, and molybdenum wire. However, the inherent brittleness and weak impact resistance of CVD diamond still need to be addressed through composite structures (e.g., PCD outer layer + CVD inner layer).

Single-Crystal Diamond: Limitations in High-Precision Surface Applications

Single-crystal diamond die inserts can achieve extremely high wire surface finish, but their anisotropic nature leads to uneven wear. Additionally, resource scarcity and high costs limit their use to fine wire or finished wire drawing dies requiring high surface quality. In recent years, synthetic single-crystal diamond technology (e.g., processes by Element Six, Sumitomo) has attempted to balance cost and performance by controlling dislocation density through substrate morphology.

Cutting-Edge Innovations and Performance Optimization of Die Insert Technology

Coating Technology and Structural Design

Nanocrystalline diamond coatings (e.g., Ajex & Turner's VNT Nano Split Die) utilize vapor deposition of multi-layer diamond films, reducing the friction coefficient by 30% and increasing production efficiency by approximately 3–4%. When combined with stainless steel die housings, such coatings can achieve a service life more than 10 times that of traditional PCD dies, without the need for polishing maintenance.

Mechanical Optimization of Hole Type Design

Straight-hole types (taper series), with their flat working cone surfaces and clearly defined zones, reduce drawing force by 20% and increase service life by 3–5 times compared to curved types (R series). By extending the lubrication and working zones and enhancing the "wedge effect," a more stable lubricating film can be formed during high-speed drawing.

Temperature Control Technology for Improved Material Deformation

Recent studies show that applying heating control to the die (e.g., Warm Die Technology WD), raising the wire surface temperature to 300°C, can optimize the deformation uniformity of materials like TWIP steel by adjusting the stacking fault energy (SFE), improving drawability by 33%.

Industry Challenges and Future Development Directions

Technical Bottlenecks

PCD Die Inserts: Graphitization of cobalt at high temperatures limits their application in extreme conditions.

CVD Die Inserts: Insufficient toughness leads to poor crack resistance, and processing precision requirements are stringent.

Conclusion: Technological Synergy Drives Industry Transformation

The competition and complementarity among PCD, CVD, and single-crystal diamond die inserts are advancing wire drawing dies from "general-purpose tools" to "customized solutions." In the future, through the integration of material innovations (e.g., nanocoatings, composite substrates), structural optimizations (e.g., straight-hole designs, temperature-controlled systems), and intelligent detection technologies, wire drawing die inserts are expected to achieve greater breakthroughs in high-end fields such as aerospace wires and micro-fine wires for electronic devices, injecting new momentum into global manufacturing.