How to Manufacture PCBN Inserts

The production process of PCBN (Polycrystalline Cubic Boron Nitride) inserts is a sophisticated integration of material purification, high-temperature high-pressure sintering, precision machining, and performance optimization. The core stages are detailed below:

I. Raw Material Preparation and Purification

The core materials for PCBN inserts are cubic boron nitride (CBN) micropowder, supplemented with binders (metallic or ceramic) and a carbide substrate.

Material Selection: CBN micropowder must meet requirements for high purity (≥99.9%) and uniform particle size (typically 0.5~30μm; finer grains for finishing, coarser grains for high-wear resistance applications). Binders are categorized into metallic types (e.g., Co, Ni, Ti) and ceramic types (e.g., TiN, TiC, Al₂O₃). Metallic binders enhance toughness, while ceramic binders improve high-temperature stability.

Purification Treatment: Impurities in CBN micropowder, such as pyrophyllite, graphite, metallic impurities, and adsorbed oxygen/moisture, must be removed through multi-step chemical processing:

Treatment with NaOH at approximately 300°C to remove pyrophyllite and hexagonal boron nitride (HBN).

Boiling with perchloric acid to remove graphite.

Boiling with HCl to remove metallic impurities, followed by rinsing with distilled water until neutral. Binders (e.g., Co, Ni, Al) undergo hydrogen reduction to remove surface oxides.

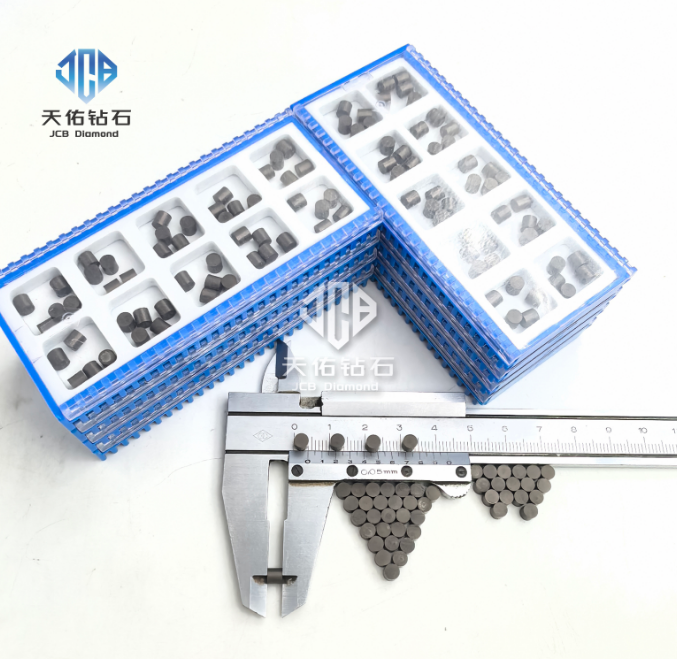

![]()

II. High-Temperature High-Pressure Sintering Process

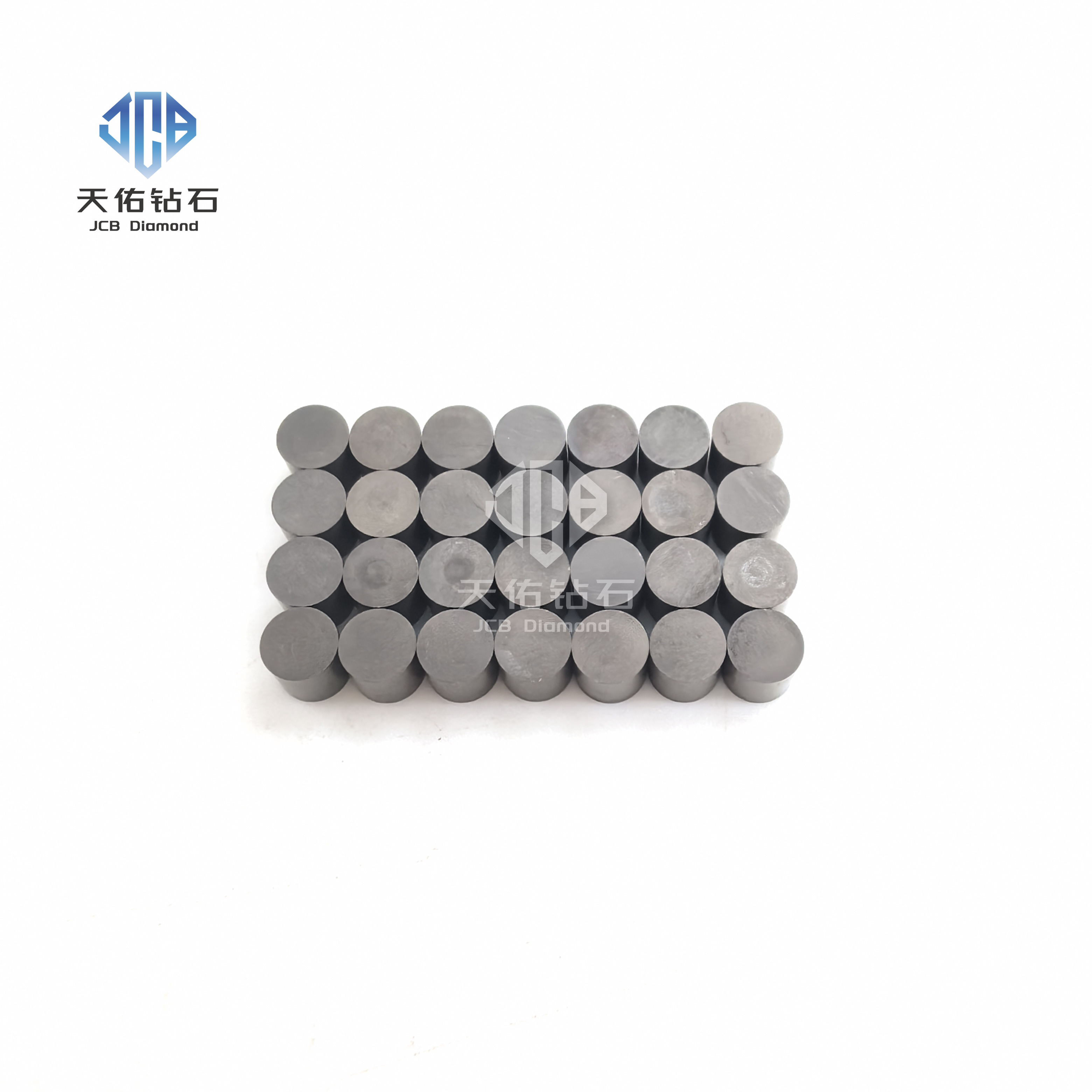

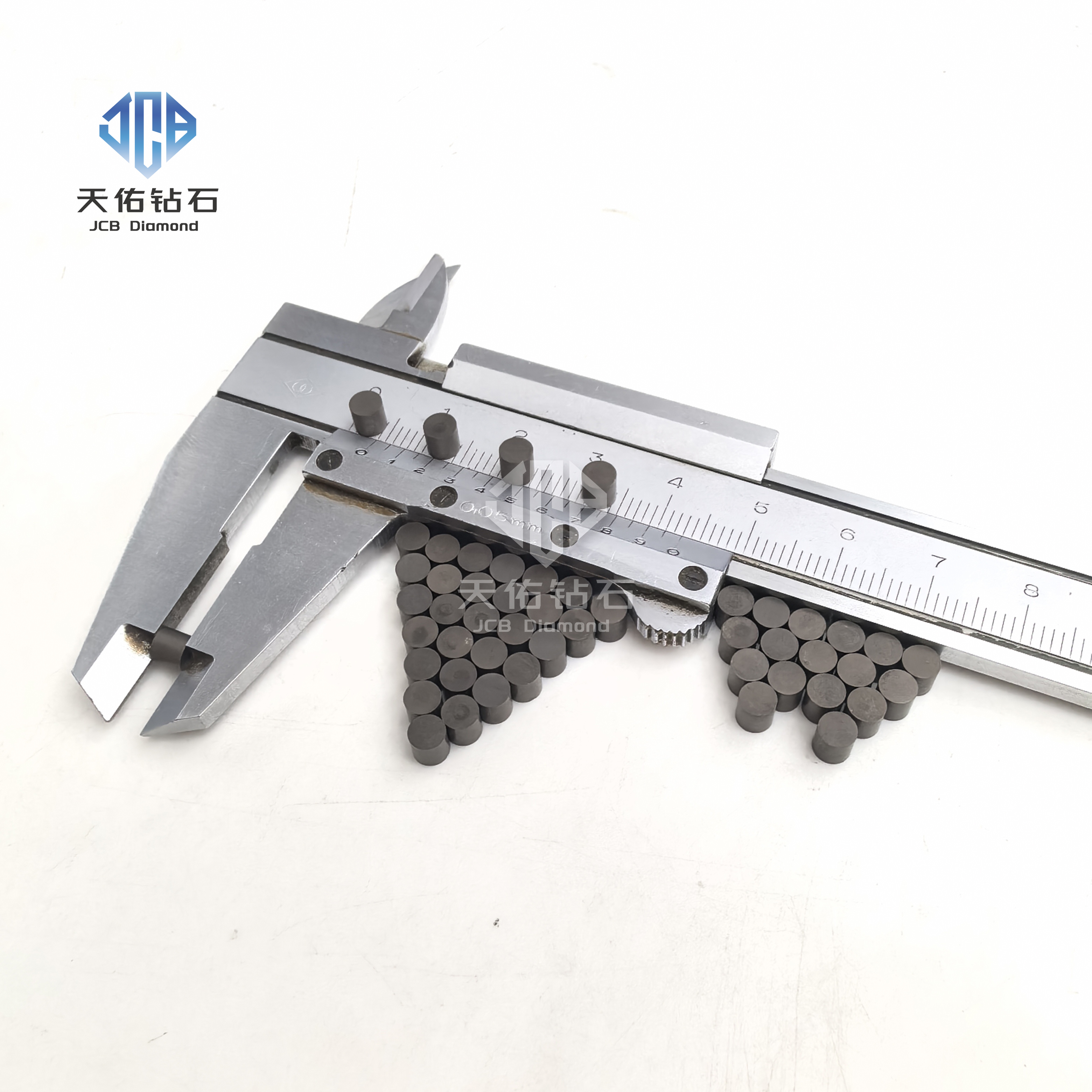

This is the critical step for forming PCBN inserts, divided into composite sintering (bonding the CBN layer to the carbide substrate) and solid sintering (pure CBN without a substrate). The mainstream process is the secondary consolidation method:

Mold Loading: Purified CBN micropowder and binder are mixed in proportion (binder content typically 10%~15%) and loaded into a graphite mold. For composite blanks, a carbide substrate (e.g., cobalt-containing tungsten carbide alloy) must be placed beneath the CBN layer.

Sintering Conditions: Using a specialized press (six-anvil or two-anvil), apply a pressure of 5~8 GPa and heat to 1200~1800°C, holding for several minutes to hours. During this process, CBN grains form covalent bonds or achieve densification via liquid-phase diffusion of the binder.

If metallic binders (e.g., Co) are added, the sintering temperature can be moderately lowered, and Co from the carbide substrate may infiltrate the CBN grain boundaries, strengthening the interlayer bond.

For pure CBN sintering (binderless), densification relies on the recrystallization and growth of CBN grains, resulting in extremely high hardness but poorer toughness.

III. Precision Machining and Edge Grinding

The sintered blank requires multiple processing steps to become a finished insert:

Cutting and Brazing: Composite blank are first cut into insert preforms, then brazed onto tool shanks; solid sintered blocks proceed directly to edge grinding.

Edge Grinding Process:

Rough Grinding: Uses 180~240 grit resin-bond diamond grinding wheels with a feed rate of 0.01mm/double stroke for preliminary shaping.

Fine Grinding: Uses W10~W14 grit wheels with a feed rate of 0.005mm/double stroke to improve surface accuracy.

Lapping: Uses W5~W3 diamond grinding wheels or lapping paste to achieve a cutting edge roughness of Ra 0.1~0.4μm, meeting the precision requirements for "hard turning instead of grinding".

IV. Coating Technology (Optional)

To further enhance performance, some PCBN inserts undergo coating treatment:

Coating Materials: Commonly used are TiN, Al₂O₃, AlTiN, CVD diamond, etc., with thicknesses of 2~30μm.

Coating Process:

Pre-treatment: Clean the insert surface of oil and contaminants.

Deposition: Use Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) technology to form a uniform coating on the insert surface.

Post-treatment: Heat treatment ensures strong bonding between the coating and substrate while preventing surface blackening (requires controlled temperature and atmosphere). Coatings significantly improve wear resistance, anti-adhesion properties, and tool life.

V. Testing and Quality Control

Performance Testing: Includes physical properties like hardness (HV 2600~3600), flexural strength, thermal conductivity, and cutting life tests under simulated working conditions.

Microscopic Inspection: Uses high-power electron microscopes (SEM, TEM) to observe the bonding state of CBN grains, checking for micro-cracks or impurities; the cutting edge must be free of microscopic defects invisible to the naked eye, otherwise chipping may occur.

Dimensional Accuracy: Checks geometric tolerances, surface roughness, M-value (key insert dimension), etc., to ensure compliance with machining requirements.

Through precise control of the above processes, PCBN inserts achieve a combination of high hardness, strong wear resistance, and excellent thermal stability, making them core tools for machining hardened materials above HRC 45 (such as hardened steels, chilled cast irons). Performance differences between models essentially result from the customized design of raw material ratios, sintering processes, and coating technologies.