Advanced sintering techniques and microstructure engineering unlock new possibilities for tailored cutter solutions in oil & gas, geothermal, and mining applications.

The choice between thick (e.g., 2–4 mm diamond layer) and thin (e.g., 0.5–0.7 mm) PDC cutters hinges on a trade-off between impact resistance and abrasive wear resistance. Thicker diamond layers, achieved through advanced high-pressure sintering (up to 8 GPa), excel in hard, abrasive formations like granite or interbedded rocks. For example, Stinger™-shaped thick cutters reduce average cutting force by 46.14% and energy consumption by 34.09% compared to conventional PDC cutters, leveraging tensile stress rather than shear stress for rock fragmentation. In contrast, thinner cutters, often using finer diamond grits, prioritize wear resistance for consistent performance in homogeneous, less challenging formations.

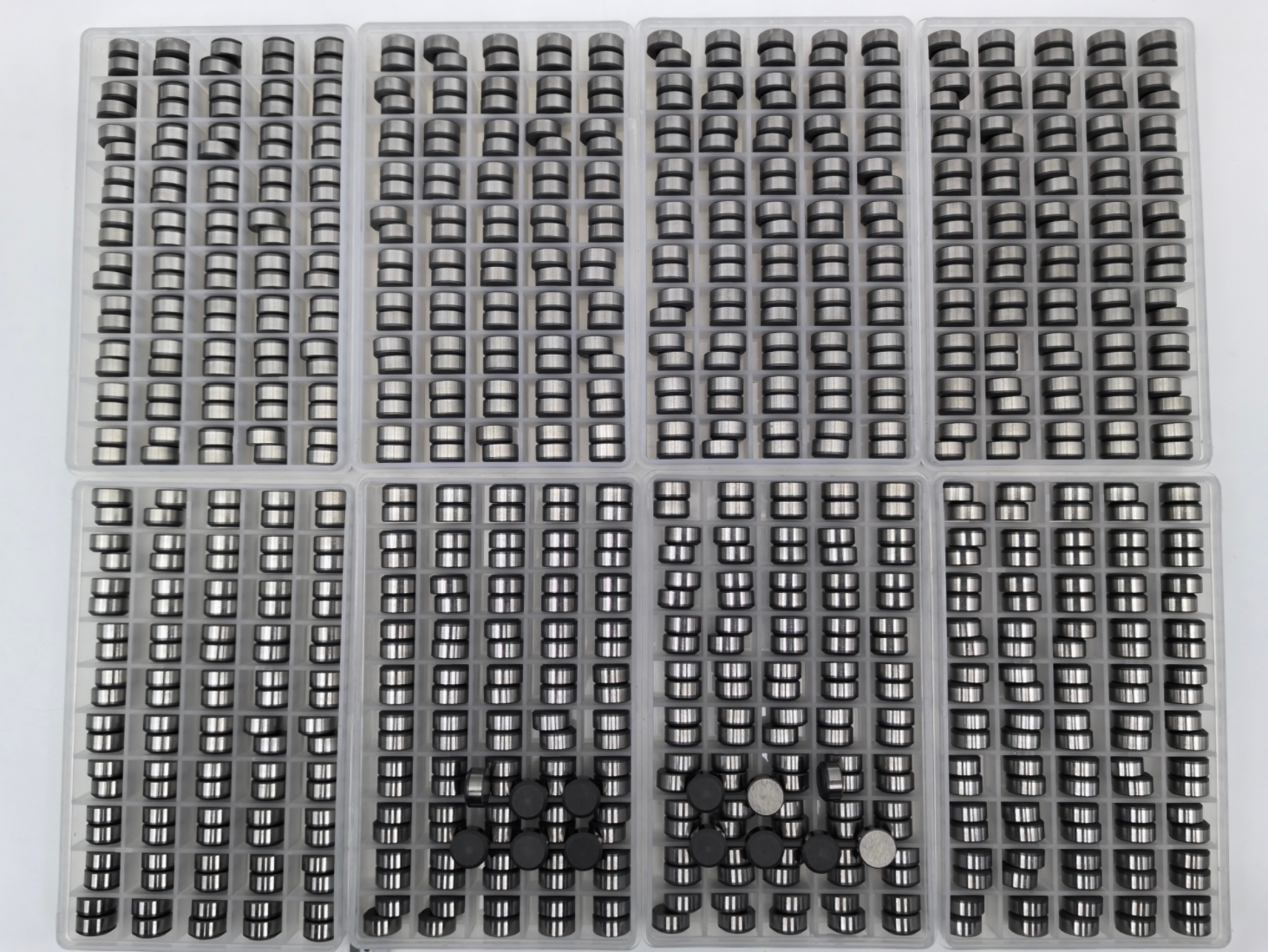

PDC cutter production begins with synthesizing diamond micropowder (0.5–30 μm) and binders (e.g., Co, TiC, or ceramic additives) under extreme conditions:

High-Pressure Sintering: At 5–10 GPa and 1,000–2,000°C, diamond particles form a D-D bond structure with metallic binders filling interstitial spaces. Thicker layers require higher pressures (up to 8 GPa) to enhance diamond density and interparticle bonding, though this may increase residual stress.

Post-Sintering Processing: Critical steps include electrical discharge machining (EDM) for shaping, vacuum brazing (below 700°C) to prevent graphitization, and diamond grinding with resin-bonded wheels or EDG technology to achieve edge sharpness (Ra ≤0.4 μm).

Microstructure Engineering: Innovations like multi-modal diamond mixes, non-planar interfaces, and leaching (removing cobalt to reduce thermal degradation) optimize both impact and wear resistance. For instance, layered diamond tables combine coarse-grained cores (for toughness) with fine-grained surfaces (for wear resistance).

Thermal Management: Thicker cutters with leached diamond layers withstand temperatures exceeding 800°C, mitigating microcrack propagation and graphite formation. Polished surfaces further reduce friction heat, extending tool life.

Cutting Mechanisms: Thick, shaped cutters (e.g., Stinger designs) produce larger rock chips and "V"-shaped trajectories, reducing mechanical specific energy (MSE). In geothermal drilling, they emulate roller-cone crushing while maintaining PDC-style shearing, boosting ROP in high-WOB environments.

Trade-Offs: Thinner cutters, though less impact-resistant, minimize residual stresses and are ideal for steady-state drilling in uniform formations.

Oil & Gas Drilling: PDC bits, comprising 75–80% of the global drill bit market, leverage thick cutters for deep, hard-rock formations (e.g., offshore and shale reservoirs). Thinner variants dominate in softer, consistent strata.

Geothermal and Mining: Thick PDC cutters demonstrate superior performance in high-vibration environments, such as geothermal wells, where impact resistance is critical. In mining, medium-thickness cutters balance speed and durability for Casing Cutting operations.

Emerging Uses: Hybrid designs (e.g., Crush & Shear bits) combine thick and thin cutters to address complex lithologies, while nano-coated variants enhance thermal stability for ultra-deep drilling.

The PDC cutter market (projected to reach $1.43 billion by 2032) will prioritize application-specific designs. Key trends include:

Advanced Materials: Nano-polycrystalline diamond (NPD) and tailored diamond grit distributions to simultaneously boost wear and impact resistance.

Digital Integration: AI-driven modeling of cutter-rock interactions for optimized bit designs.

Sustainability: Cutters for geothermal and ESG-focused drilling, reducing energy consumption via lower MSE.

Conclusion

The thick-versus-thin PDC cutter debate is not about superiority but contextual fit. As sintering technologies and microstructure engineering evolve, the industry moves toward hybrid solutions that dissolve traditional trade-offs, enabling unprecedented efficiency in the energy and mining sectors.