Materials used for manufacturing wire drawing dies include: alloy steel, cemented carbide, natural diamond, synthetic single-crystal diamond, synthetic polycrystalline diamond, ceramics, and dies produced through various chemical heat treatments, chemical vapor deposition, and physical vapor deposition methods.

(1) Synthetic Single-Crystal Diamond (MCD) Dies

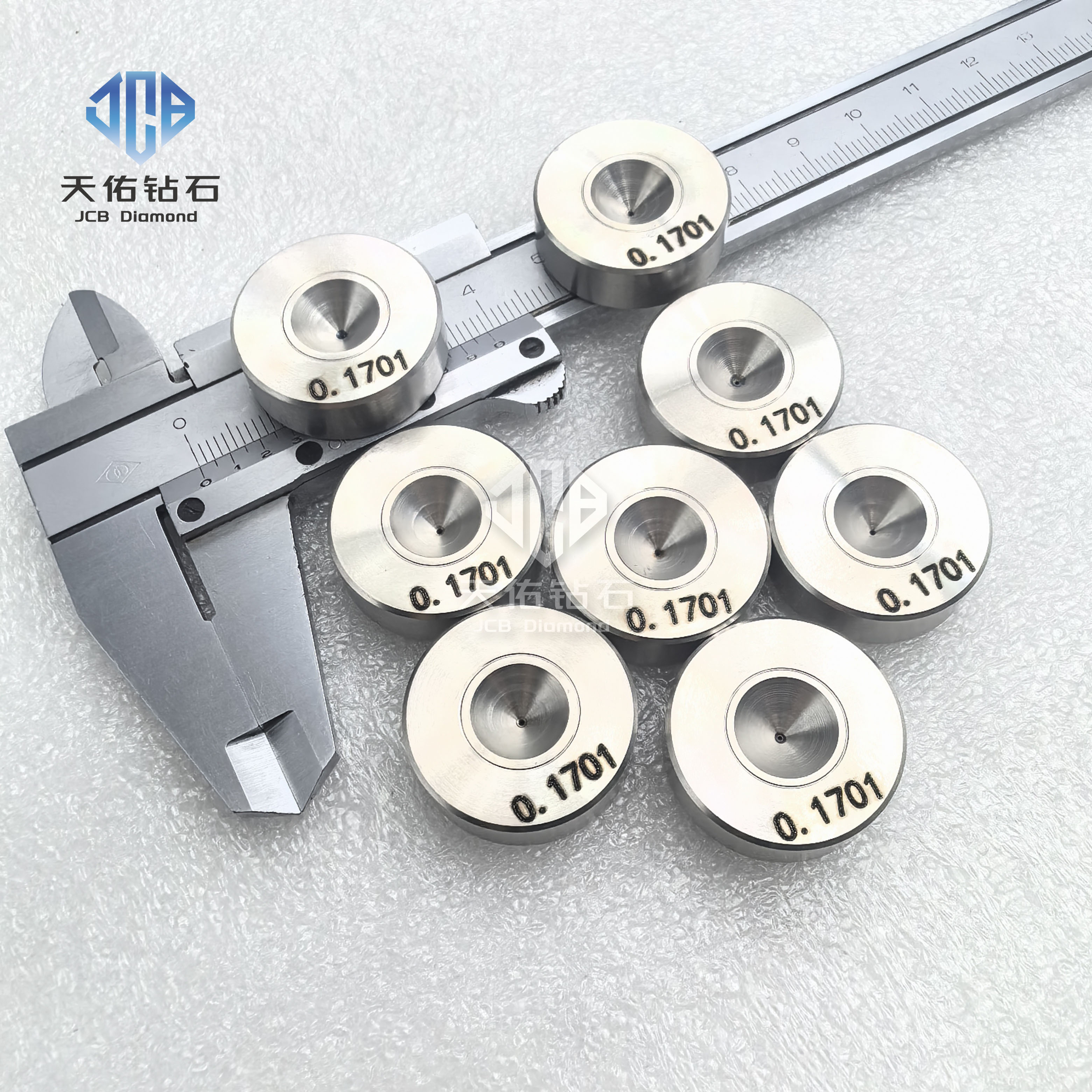

In the late 1980s, De Beers of the UK collaborated with Sumitomo Electric Industries of Japan to develop a novel diamond die blank. It possesses the characteristics of natural diamond, features an absolutely regular diamond surface, performs exceptionally well under operational conditions, and exhibits strong wear resistance. Its applicability is equivalent to natural diamond with diameters below 0.5mm.

Given that natural diamonds and high-quality synthetic polycrystalline diamonds are significantly more expensive than cemented carbide, various methods have been employed over the years to modify the alloy composition of cemented carbide wire drawing die surfaces and the structure of the dies themselves. This aims to extend their service life and meet the demands of high-speed wire drawing.

Between 1968 and 1978, boron diffusion into cemented carbide began worldwide. China conducted boron diffusion trials at Tianjin First Steel Rope Factory in 1978. Comparative tests under identical conditions generally showed a 2-3 times increase in average performance. However, boron diffusion poses challenges during cleaning. In 1986, the international community adopted physical vapor deposition (PVD) and chemical vapor deposition (CVD) methods under vacuum conditions to coat wire drawing die holes with titanium carbide or titanium nitride. This approach enhances die hole hardness, wear resistance, and density. However, this method requires specialized, costly equipment and strict process control to achieve optimal results.

In recent years, with the increasing maturity of chemical vapor deposition (CVD) diamond film technology, a more reasonable approach—considering both die cost and performance—has been to coat the inner surface of carbide wire drawing dies with a uniform diamond film layer that meets adhesion requirements. Some researchers have also focused on extending die life by modifying die structures, such as developing rotary dies and detachable assembly dies.

Generally, selecting wire drawing die materials requires simultaneous consideration of both the die material and the material of the item being drawn. While ensuring the drawn item achieves a relatively glossy surface finish, it is also crucial to maximize die service life. Furthermore, the wear resistance of both materials should not differ excessively to prevent excessive wear that could lead to product failure or die damage/scrap. Economic factors must also be considered to maximize profitability while minimizing costs, all while ensuring normal production operations.