What are CVD seed crystals? Simply put, they serve as the “seed” substrate guiding the epitaxial growth of diamond crystals during the chemical vapor deposition (CVD) process for producing synthetic diamonds. Serving as the core reference for diamond growth, CVD seeds are typically precision-machined from high-quality natural diamonds or high-pressure high-temperature (HPHT)synthetic diamonds. They provide a stable crystalline structure template for subsequent crystal growth, with their quality directly determining the performance and quality of the final diamond product. As such, they represent the foundational critical material at the source of the synthetic diamond supply chain.

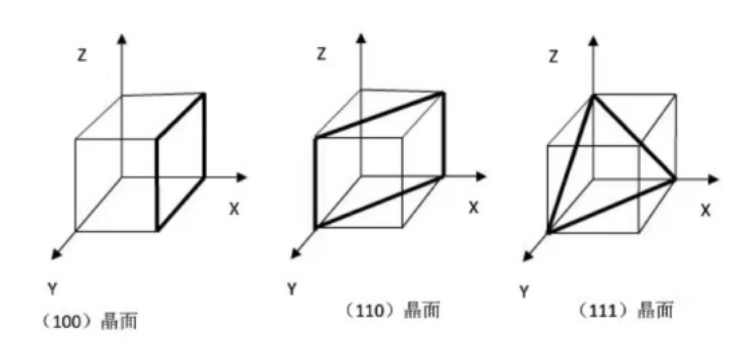

Crystal orientation is a core critical property of CVD seed crystals, referring to the direction of atomic arrangement within the crystal. It plays a decisive role in determining the morphology and properties of diamond growth.CVD seed crystals exhibit crystal orientations of (100), (110), and (111), each suited for distinct applications: (100) and (110) orientations are used for growing jewelry-grade rough diamonds, while industrial single crystals require no specific orientation.

The production of high-quality CVD seed crystals involves extremely high barriers to entry, requiring multiple precise and rigorous manufacturing processes. The core workflow can be divided into three steps.

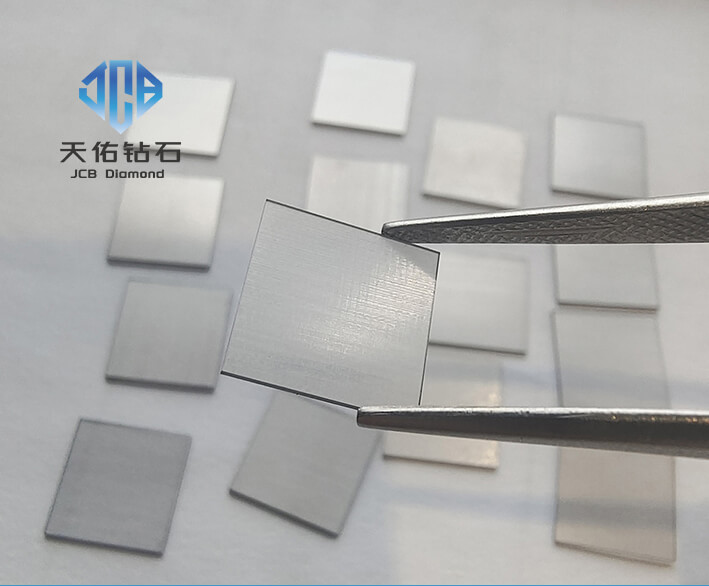

The first step is raw material selection, prioritizing natural diamonds or high-pressure high-temperature (HPHT) synthetic diamonds with high purity and minimal defects as the substrate. This is fundamental to ensuring the seed crystal's foundational quality. The second step involves directional machining. Through precision techniques like laser cutting and grinding, the substrate is processed into predetermined dimensions—currently, mainstream industrial-grade CVD seeds measure 5-15mm square. Producing oversized seeds (20mm+) is a key technical challenge in large-diamond fabrication. This stage also demands precise control over crystal orientation to prevent subsequent growth defects. The third step involves precision polishing and inspection. The processed seed crystal undergoes nanoscale polishing to ensure surface roughness meets standards, preventing interference with epitaxial growth. Subsequently, specialized inspection equipment is used for impurity detection and crystal orientation calibration. Furthermore, thickness control is critical, with conventional thicknesses ranging from 0.3 to 0.6 mm. This must balance structural integrity during growth with sufficient allowance for subsequent machining.