Drilling and mining

Diamond drill bits are widely used in metallurgical, coal, petroleum and other geological exploration and exploitation fields. Because of its high hardness, it can drill through steel drilling through the hardest rock formations that are difficult to drill, and it is very durable, and the average footage is twice or even several times higher than the carbide drill bit, so the number of drilling can be greatly reduced. Drilling speed is fast, especially when drilling hard and dense rock. For example, drilling particularly hard class 10 rocks, small diameter diamond drilling can reach 1-2m/h, while steel drilling is only 0.2-0.3m/h. Small diameter diamond drilling can save steel, reduce labor intensity, reduce the accident rate, and the hole inclination is small, the hole bending is small, reduced to about one degree per meter; The core collection rate is high, generally up to 90%. The total cost of drilling is significantly lower than that of using carbide bits, generally reducing by 30%-40%.

In recent years, the quality and type of diamond composite PDC have changed greatly. Diamond composite PDC has been widely used in many fields such as geological exploration, coal mining and oil drilling, and various industries have put forward higher requirements for its performance, which further promotes the rapid development of diamond composite PDC technology. In recent years, due to its excellent performance characteristics, diamond composite PDC has gradually begun to play an important role in more new fields.

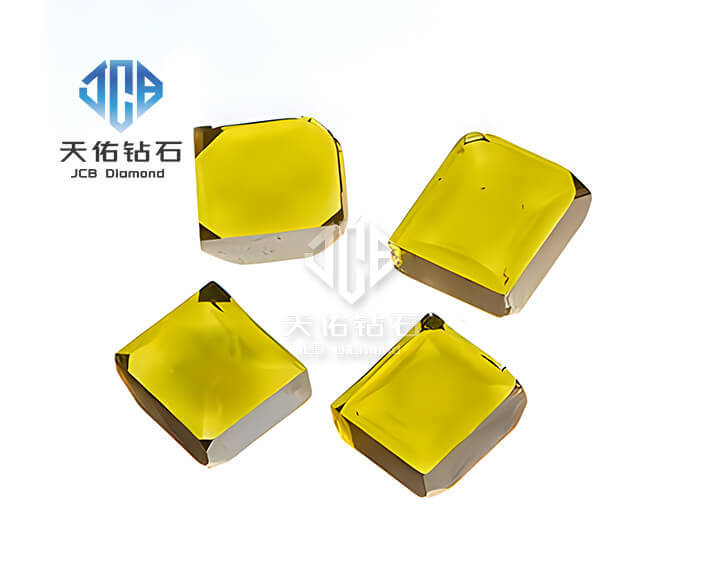

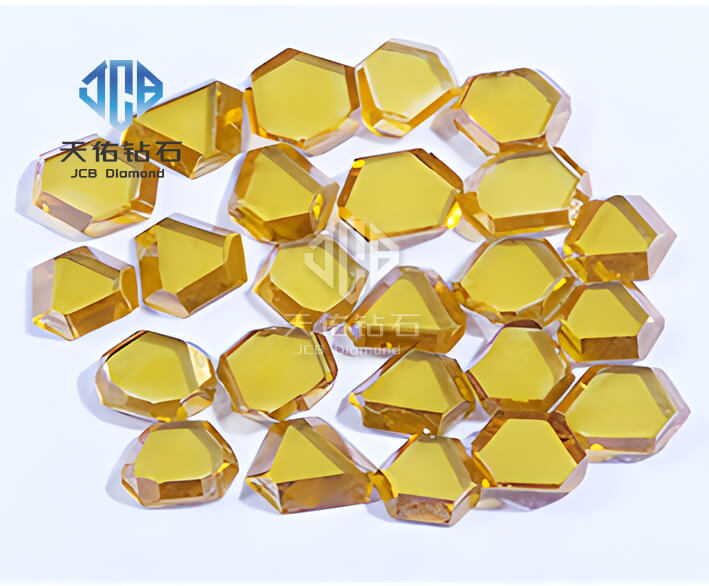

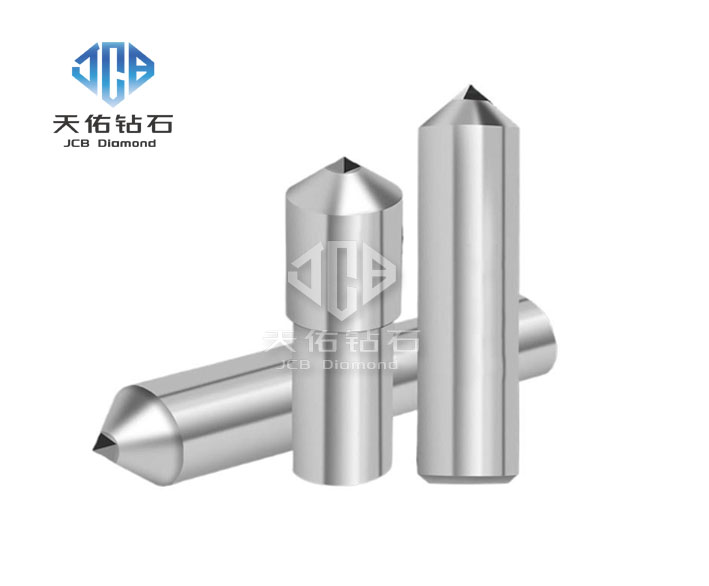

Our JSD synthetic diamond rough, coarse grained synthetic diamond, polycrystalline diamond, diamond composite PDC and TSP are widely used in drill bit manufacturing, oil and gas drilling, geological exploration, coal mining and stone processing.