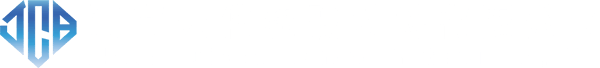

Optical cold working

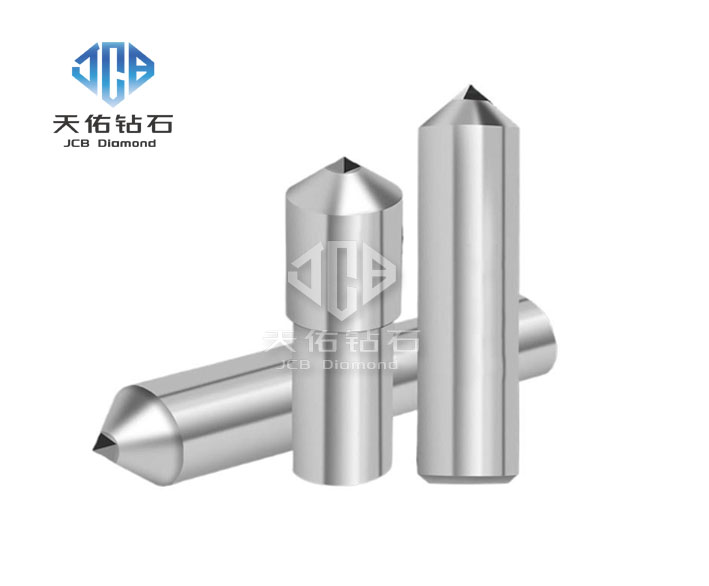

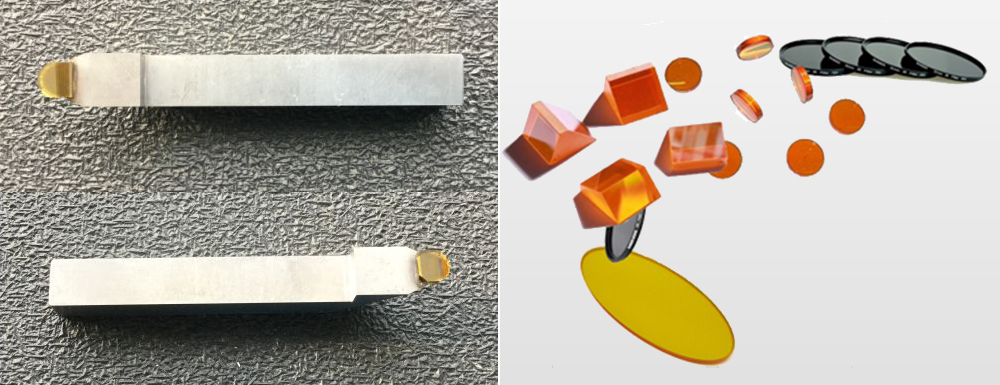

The diamond single crystal cutter developed by us is widely used in ultra-precision turning and milling of sapphire, zinc selenide, zinc sulfide, silicon, Ge, calcium fluoride, barium fluoride, optical glass, ceramic crystal and other optical materials, with the characteristics of high machining precision, high efficiency, high surface quality, long service life and so on.

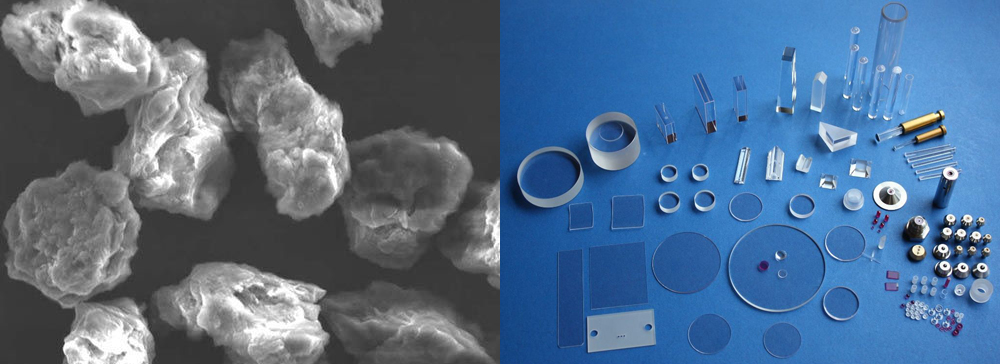

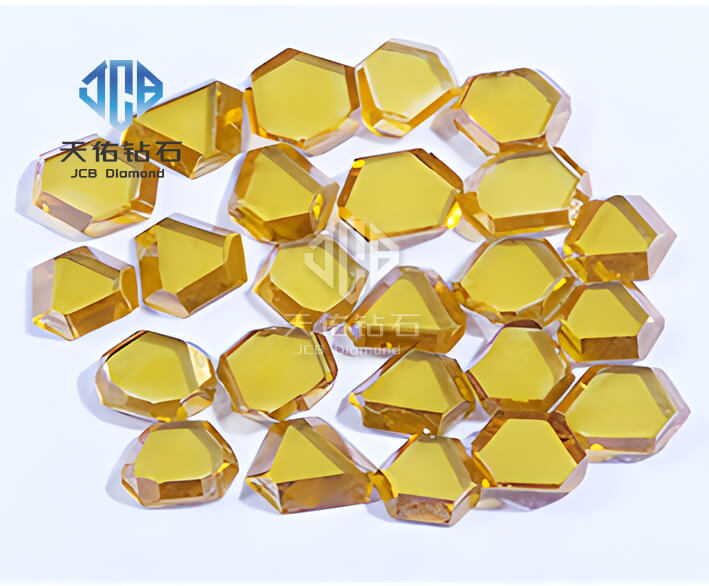

Our JPDM, polycrystalline diamond micropowder, is a nano-diamond polymer synthesized by transient ultra-high pressure and high temperature explosion, which is similar to carbonados found in a small number of meteorites in nature. It is a polycrystal composed of cubic diamond and hexagonal diamond, with high toughness, high self-sharpness and high hardness and other characteristics, as a new grinding material, sapphire grinding processing has other materials ideal advantages. The grinding efficiency is 2 to 4 times that of single crystal diamond, and it does not produce scratches and has a high finish.