1. Product Overview

Thediamond impregnated drill bit is a highly efficient and advanced rock drilling tool that utilizes diamond as the abrasive material. Unlike surface-set bits with large, exposed diamonds, the impregnated bit employs a more complex and efficient technology.

Structure & Working Principle:

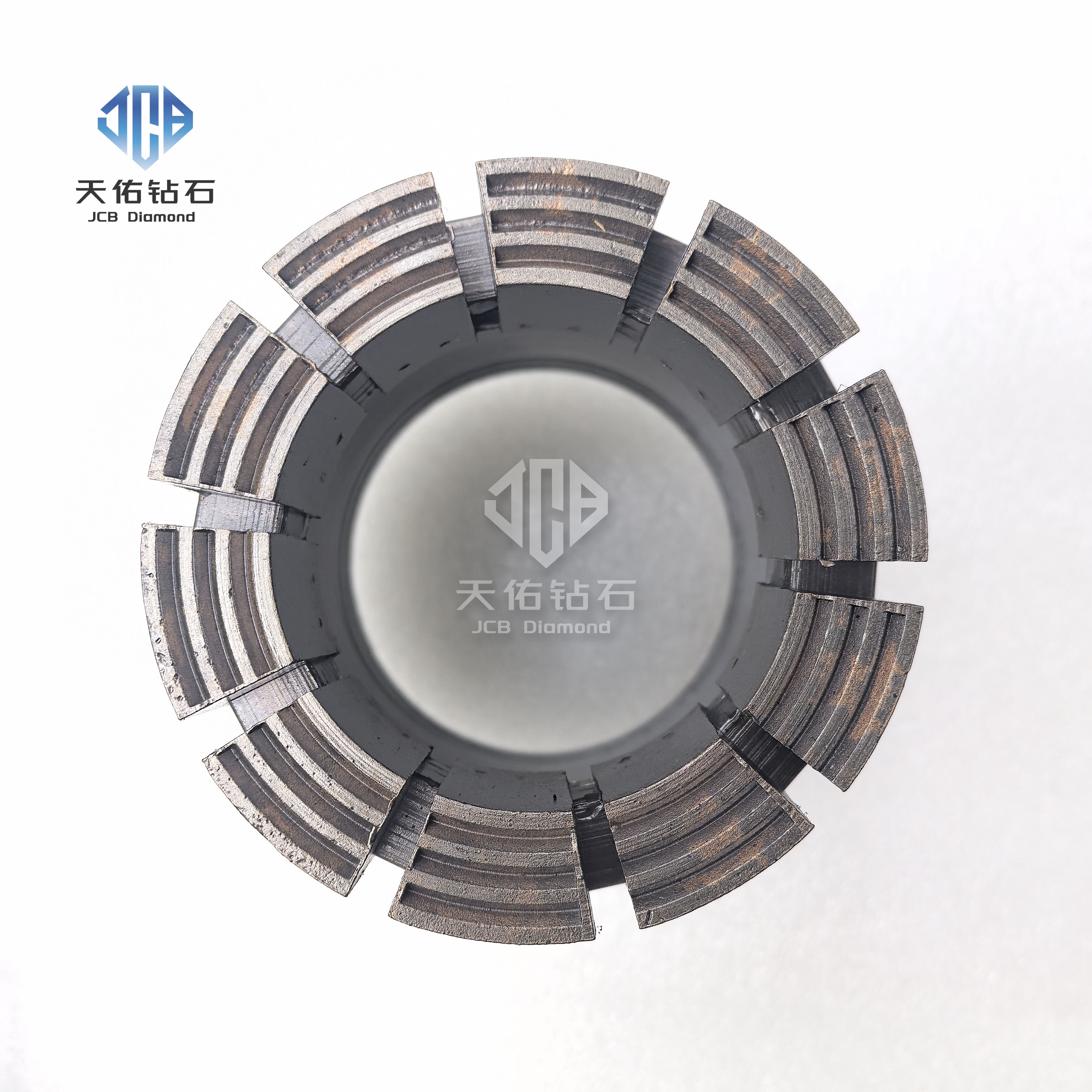

Structure:The bit consists of a steel body (black section) and a matrix (silver serrated crown section).

Steel Body:Provides structural support and connection to the drill string.

Matrix (Working Layer):A metal-based composite sintered from various metal powders (e.g., tungsten, cobalt, copper). Synthetic diamondmicroparticles are uniformly impregnated throughout the matrix rather than being surface-set.

Working Principle (Self-Sharpening Effect):During drilling, the matrix gradually wears away due to friction with the rock. This continuous wear exposes fresh, sharp diamond particles, maintaining an efficient cutting surface while shedding dulled grains. This self-sharpening mechanism ensures sustained performance and extended service life.

2. Key Features & Advantages

Exceptional Wear Resistance & Long Service Life:The diamond-impregnated matrix provides a thick, durable working layer, significantly outperforming surface-set bits in longevity.

High Penetration Rate:The self-sharpening effect ensures consistent drilling efficiency, particularly in medium-hard to extremely hard formations.

Smooth Operation & High-Quality Coring:Designed for core drilling, the bit enables stable cutting action, facilitating the recovery of intact, high-quality core samples.

Customizable Adaptability:By adjusting the matrix composition (hardness/wear resistance) and diamond concentration, the bit can be tailored for formations ranging from soft to extremely hard rock.

3. Technical Parameters (Estimated)

Outer Diameter:Designed for optimal core recovery, standard diameters range from 3.5 to 12.25 inches.

Cooling Channel Design:Impacts heat dissipation efficiency; minimum waterway width of 5.5mm enhances thermal shock rock-breaking effectiveness.

Diamond Concentration:Customized based on formation abrasiveness and hardness.

4. Primary Applications

This bit is essential in geological exploration, engineering surveys, and resource extraction:

Mineral Exploration:Retrieving core samples from metal (e.g., gold, copper, iron) and non-metal deposits (e.g., limestone, coal) for grade and reserve analysis.

Construction & Geohazard Investigation:Used in foundational surveys for bridges, tunnels, and slopes, assessing rock stability and landslide risks.

Water & Geothermal Well Drilling:Drilling deep bedrock wells for groundwater or geothermal energy extraction.

Scientific Drilling:Supports continental and environmental research by obtaining deep crustal samples.

5. Compatible Equipment & Usage Guidelines

Compatible Equipment:Requires pairing with core barrels, drill rods, and hydraulic core drilling rigs (portable or large-scale, depending on depth and diameter requirements).

Usage Guidelines:

Formation Matching:Select the appropriate matrix formula and diamond concentration based on rock hardness, abrasiveness, and integrity.

Parameter Optimization:Optimize weight on bit, rotation speed, and flushing fluid flow to maximize efficiency and bit protection.

Cooling & Cuttings Removal:Ensure sufficient flushing fluid (water or mud) circulates through the bit to cool the matrix and remove debris.