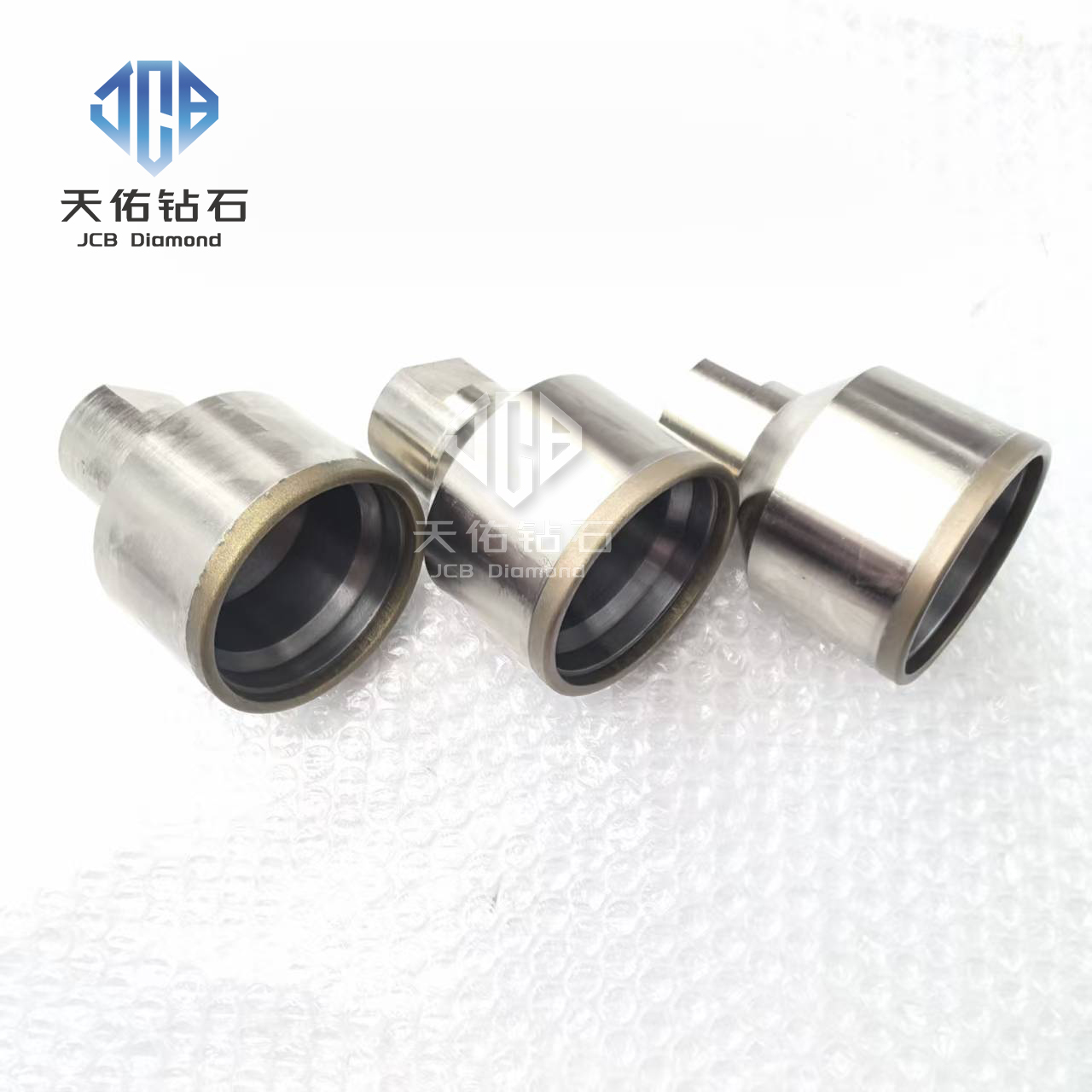

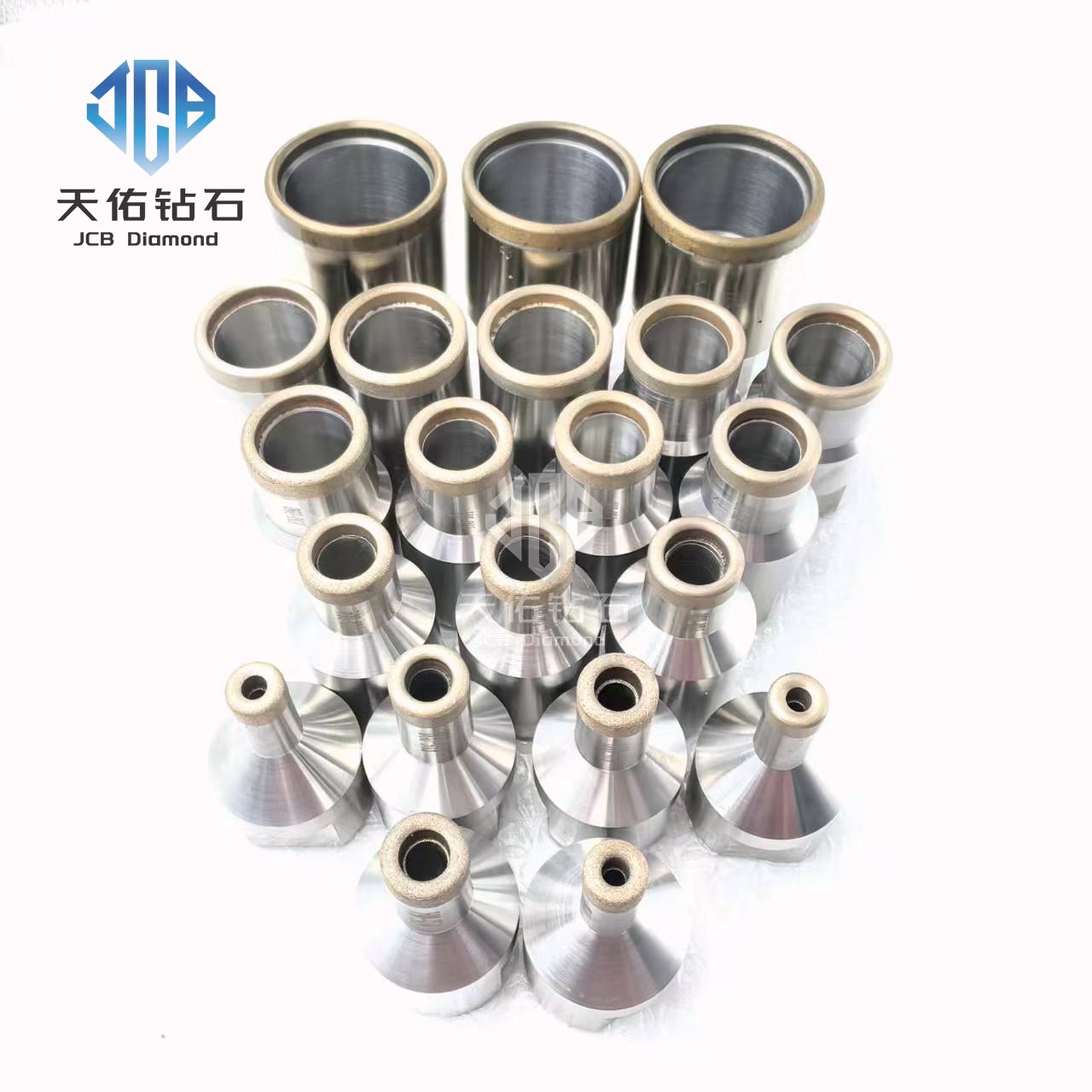

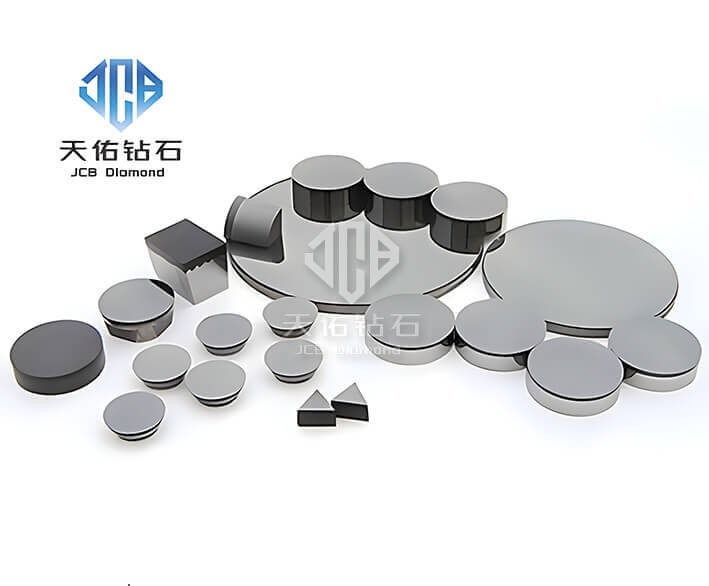

Manufacturing Process

This product utilizes advanced diamond sintering technology, where precisely graded polycrystalline diamond particles are permanently bonded with special metal binders through high-temperature and high-pressure processes. Controlled sintering curves and atmosphere protection ensure metallurgical-grade bonding strength between the diamond particles and the substrate. The working layer of the grinding head is precision-trimmed with high-precision CNC dressing technology to guarantee a radial runout of ≤0.01 mm. The tool body is made of special alloy steel treated with unique heat treatment processes, ensuring exceptional rigidity and balance during high-speed rotation.

Product Features

Exceptional Machining Precision

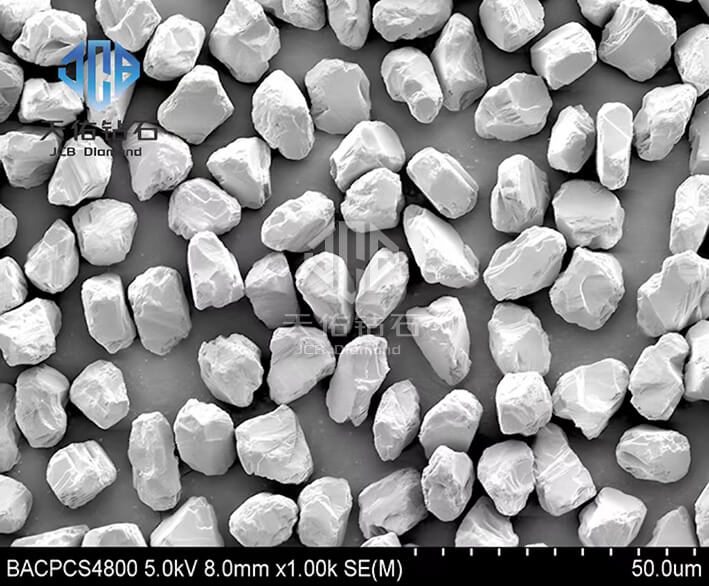

The diamond concentration in the working layer can be customized, with grit sizes ranging from 80# to 1200#, enabling a complete process chain from rough to fine grinding. Achievable surface roughness: Ra 0.1 μm.

Significantly Extended Service Life

Offers 8-10 times longer lifespan compared to traditional resin grinding heads. Maintains stable material removal rates during continuous processing, effectively reducing equipment downtime for tool changes.

Optimized Cutting Dynamics Design

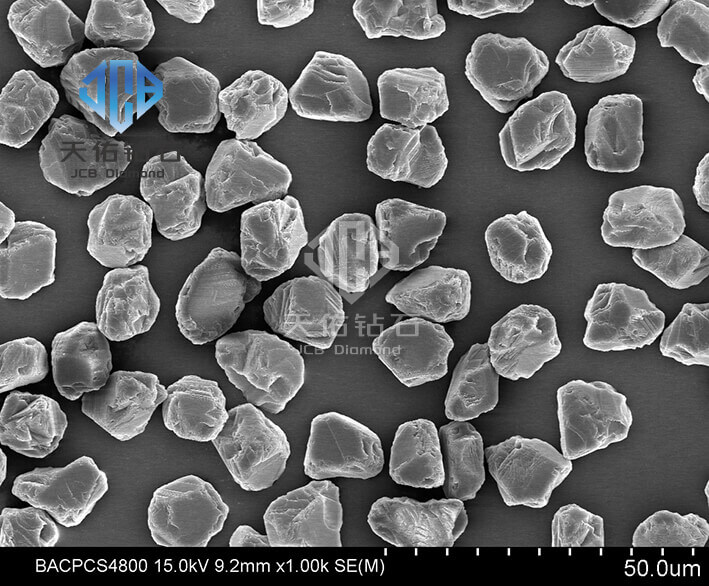

Unique 3D interleaved arrangement technology ensures gradient distribution of diamond particles, balancing sharpness and wear resistance. Cutting force is reduced by 30% compared to conventional products.

Broad Environmental Adaptability

Optimized for optical glass processing environments, suitable for various working conditions such as water-based coolants and oil-based cutting fluids, while maintaining stable chemical inertness.

Professional Applications

Precision Optical Component Forming: Suitable for contour grinding of hard and brittle materials such as sapphire glass, glass-ceramics, and optical crystals.

Fine Machining of Optoelectronic Components: Specifically designed for chamfering camera lenses, VR optical lenses, laser collimators, and other components.

Display Panel Processing: Ideal for special-shaped hole machining and edge finishing of OLED substrate glass and cover glass.

Instrument and Gauge Manufacturing: Suitable for step-hole grinding of high-precision optical instrument windows and observation lenses.

With its unique structural design and optimized material formulation, this product delivers excellent cutting performance while effectively addressing common issues in optical glass processing, such as chipping and micro-cracks. It is an ideal solution for efficient and precision machining of high-value optical components.